Catalog excerpts

PADDLE FINISHERZPF The two-stage ZPF Paddle Finisher filter permits eliminating thick pulp and refining the juice by means of a high speed paddle system and its regulation in the extraction phase. It has a control system to regulate humidity in waste and a general on-off panel. FILTERING SYSTEM HUMIDITY CONTROL NORMAL APPLICATIONS The three paddles on the inside that rotate at high speed, making the product pass through the perforated stainless steel mesh to achieve the desired result. The pulp refining degree can be varied according to the product needs by selecting the mesh perforation diameter Standard: 0.8 mm. Able to regulate the humidity in waste by means of a counterweight system in the extraction opening. Separation of pulp from extracted juice and recovery of soluble solids contained in the pulp (pulp washing). Adequate for all types of citrus juices and pomegranate juices. Recording and electronic control of all process parameters with temperature and power regulator. Motor (with reduction via pulley) Product input Product output Perforated mesh Bearings Cleaning Lower tank Belt Dimensions (length x width x height) Manufactured entirely of stainless steel 7.5 Kw / 1.450 r.p.m. (490 r.p.m. in paddles) DN50 DN50 0 0.8 mm Angular contact and rigid ball bearings CIP of outer mesh by means of inner mobile ring 50 l SPC 1.354 x 900 x 780 mm AISI 304 FOOD ENGINEERING Zumex Group, S.A. ■ Tel: +34 961 301 251 ■ Fax.+34 961 301 255 ■ foodengineering@zumex.com Zumex Service ■ Tel: +34 960 800 999 ■ service@zumex.com www.zumexfoodengineering.com

Open the catalog to page 1All Zumex Food Engineering catalogs and technical brochures

-

CIP SYSTEM

1 Pages

-

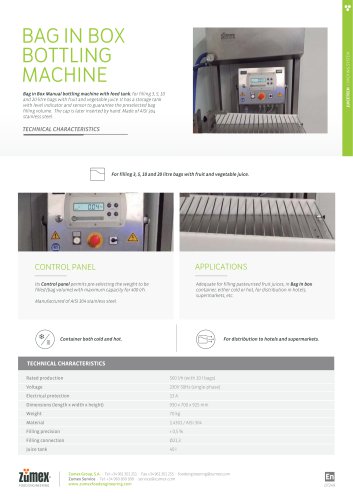

BAG IN BOX BOTTLING MACHINE

1 Pages

-

SCREW PRESS ZSP5

1 Pages

-

OIL EXTRACTOR ET6

1 Pages

-

PASTEURIZADOR FLASHZF1000

2 Pages

-

MASTERY

2 Pages

-

DEPULPER ZPD500

1 Pages

-

ELEVATOR CRUSHERZRC500

1 Pages

-

MULTIFRUIT ZMF400

1 Pages

-

CITRUS JUICE EXTRACTOR PJE

2 Pages

-

CITRUSZ450

1 Pages

-

ZPD500 / DEPULPER

1 Pages

-

Mastery Commercial Juicer

2 Pages

-

JuiceTech

7 Pages