Website:

ZUMBACH Electronic AG

Website:

ZUMBACH Electronic AG

Catalog excerpts

Modular Single Axis Laser Measuring Head for Diameter, Width, Height. Measuring Field = 60 mm (2.36 in.). ODAC® 60J The ODAC® measuring head uses the latest laser scanning 60 technology. It is manufactured with a modular design. It is available with a support rail or as individual emitter and receiver parts when a maximum of flexibility is required to install the head in any position. The ODAC® 60 head can also be installed in constricted confines or several emitter/receiver pairs can be mounted in the same plane. The head is offered with a complete range of accessories and interface units for optimal integration into almost any process and thus can be used for all products. ODAC® 60 is available in following versions: – J version (standard version) – JP version (for profile measurement) – JN version (with narrow beam for contour measurement) These versions are also available in the JS version, i.e. for the external synchronization of 2 units by means of the CI 2JS/1J unit or of multiple axis systems like the STEELMASTER SMO or SMS systems. Typical Applications • Cable extrusion, hoses, profiles etc. • Metal / steel processes such as drawing, grinding, bar, tubing etc. • Testing (NDT) for all kinds of product • Food, packing, medical tubing etc. Advantages • Very high scan rate • Highest precision • Single scan Calibration CSS • Single scan monitoring • Data rate up to 333/s (depending on version of measuring head, number of transmitted measured values as well as the baud rate of the interface) • Compact and rugged design • Flexible mounting • Special beam geometries available: – Parallel beam for profiles and similar – Narrow beam for contour measurements • Different measuring modes, e.g. for diameter, gap, penetration, multiple measurement etc. Options / Accessories (see also page 3) F versions: – Double scan rates as the standard versions, i.e. more measurements per time unit – Maximum fault detection (lumps/neckdowns) at increased line speeds – FFT/SRL analysis with higher bandwidths • Diagnostic output • Synchronization* of multiple ODAC measuring heads • Computer interface CI 1J/EN-xx for RS-232/-422/-485, Profibus DP, Ethernet TCP/IP, Profinet IO, EtherNet/IP • Protection windows • Guides (upon customer specific request) * Signal processing with special USYS unit Flexible mounting With or without rail, different measuring distances Types of Measurement 1 Diameter measurement Slit width measurement Multiple measurement Dual scanning with large measuring field (synchronized) Penetration depth measurement 7 Dual scanning XY (synchronized) Height measurement Other types of measurement on request Special Applications Measurement of hot steel with STEELMASTER systems: SMO: Oscillating 2, 3, 4 or 6 axis systems SMS: Static 2, 4 or 6 axis sy

Open the catalog to page 1

ODAC 60J with the corresponding processors The measured signals are forwarded to the processor unit through a connection cable. Signal processing, automatic line or process control, tolerance limit monitoring and many additional functions are carried out by this processor. Dual head measuring systems with USYS processor A measuring system for a dual plane (XY) measurement configuration or for a larger measuring field can be set up with two ODAC 60JK, an USYS IPC 1e / 2e processor. Configurations with CI compact boxes Host interface ODAC 60J single head configuration with computer interface...

Open the catalog to page 2

ODAC 60JK ODAC 60JSK ODAC 60JPK ODAC 60JSPK ODAC 60JNK ODAC 60JSNK Laser position ODAC 60J..K with deviation unit ODAC 60-90° Laser position Connection cable between emitter and receiver ODAC 60J ODAC 60JS ODAC 60JP ODAC 60JSP ODAC 60JN ODAC 60JSN Laser position Dimensions in mm (inch)

Open the catalog to page 3

Technical Data Measurement Model(s) Version Measuring field M 1) Min. object ø Scanning frequency standard F version scans/s Scanning speed Width of laser beam 6) 60 mm ( 2.36 in.) 100 mm Repeatability (3 σ) ( 3.94 in.) at measuring 200 mm distance D ( 7.88 in.) and averaging 300 mm time (s) (11.81 in.) 400 mm (15.75 in.) Measurement error centric at measuring distance D 2) ODAC 60JS ODAC 60JSP ODAC 60JSN Same with synchronization input Profile measurement Measurement error within 2 x value of the centric measurement error (ODAC 60xxP: 4 x value of the centric measurement error) the...

Open the catalog to page 4All ZUMBACH Electronic AG catalogs and technical brochures

-

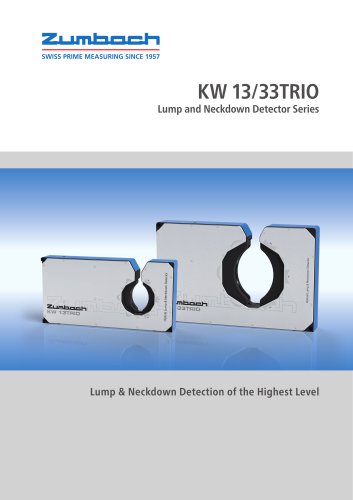

KW 13/33TRIO

4 Pages

-

UMAC® RZ35/65

2 Pages

-

UMAC® CI

2 Pages

-

UMAC® - WALLMASTER

6 Pages

-

ODAC® 34XY

4 Pages

-

ODAC® 64XY

4 Pages

-

ODAC® 2J/16J

4 Pages

-

ODAC® 13TRIO

4 Pages

-

ODAC® 33TRIO

4 Pages

-

ODAC® 63TRIO

4 Pages

-

ODAC® 14XY

4 Pages

-

ODAC® 18XY Micro

4 Pages

-

PREHEATER WST8/16/25

4 Pages

-

CELLMASTER®

4 Pages

-

PROFILEMASTER SPS 800

4 Pages

-

ODAC-USYS

6 Pages

-

ZUMBACH Electronic AG - General

32 Pages

-

CAPAC® HS

4 Pages

-

ODEX® 10

4 Pages

-

RAYEX® D XT

6 Pages

-

RAYEX® S

4 Pages

-

SIMAC® 40/70/120

2 Pages

-

LSV 1100 / 2100

2 Pages

-

PROFILEMASTER® PMM Series

4 Pages

-

USYS Touch

4 Pages

-

USYS IPCe

6 Pages

-

USYS 200

4 Pages

-

ODAC® 110XY

4 Pages

-

STEELMASTER SMR 230-400

6 Pages

-

ODAC® 550

4 Pages

-

ODAC® 310

4 Pages

-

ODAC® 230

4 Pages

-

ODAC® 160

4 Pages

-

ODAC® 100

4 Pages

-

ODAC® 113TRIO

4 Pages

-

VISU-Touch

1 Pages

-

USYS 20

4 Pages

-

CALIBRATOR SP 40A

1 Pages

-

BENDCHECK

4 Pages

-

DVO 2

2 Pages

-

DVW 1

2 Pages

-

MSD 50 /100 /200

4 Pages

-

SPARKTESTER AST

4 Pages

-

STEELMASTER SMO

6 Pages

-

STEELMASTER SMS

6 Pages

-

STEELMASTER SMR

6 Pages

-

AUTAC 300

2 Pages

-

ECOGAUGE

4 Pages