Website:

ZUMBACH Electronic AG

Website:

ZUMBACH Electronic AG

Catalog excerpts

In-Line straightness measurement using precise non-contact laser diameter gauges

Open the catalog to page 1

BENDCHECK – Straightness measurement of Bars and Pipes This non-contact measuring solution opens tremendous potential to tube and bar manufacturers for in-line quality assurance and is achieved without laborious, manual measurements. Many manufacturers of pipe and steel bar are constantly challenged to respect straightness specifications that are significant criteria's of quality. Manual inspection stations are offering only punctual checks without having the entire production under control. ZUMBACH's BENDCHECK system is installed in-line and measures the straightness of every single...

Open the catalog to page 2

SYSTEMS COMPONENTS The BENDCHECK system is available in different combinations depending on the integration into the production process and on the product dimension. BENDCHECK – Complete measuring and display system with 5 measuring stations (including head and tail bending) USYS BARMASTER BENDCHECK – Complete measuring and display system with 3 measuring stations USYS BARMASTER BENDCHECK – Measuring system with Ethernet communication port For OEM's a simplified setup is available with BENDCHECK measuring station and BENDCORE processor. BENDCORE is offering an Ethernet communication port...

Open the catalog to page 3

USYS BARMASTER DISPLAY The relevant measurements such as bending, bend angle, diameter and ovality (optionally head and tail bending) are visible at a glance. The USYS BARMASTER can collect statistical information of each piece, but also collect complete lot statistics. Operation is menu-driven via a separate touch screen with a clearly arranged and easy-to-use user interface for the entry/selection of the parameters. The measured values are displayed both numerically and graphically. Line layouts with pictograms of the connected devices are user configurable. Time or length-based trending...

Open the catalog to page 4All ZUMBACH Electronic AG catalogs and technical brochures

-

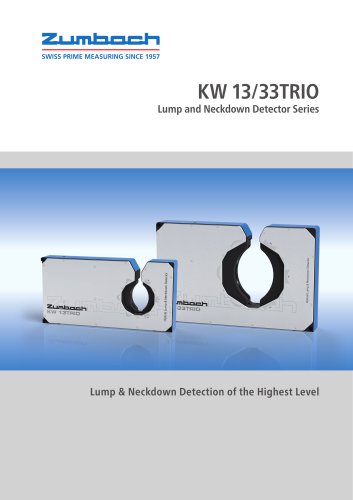

KW 13/33TRIO

4 Pages

-

UMAC® RZ35/65

2 Pages

-

UMAC® CI

2 Pages

-

UMAC® - WALLMASTER

6 Pages

-

ODAC® 34XY

4 Pages

-

ODAC® 64XY

4 Pages

-

ODAC® 2J/16J

4 Pages

-

ODAC® 13TRIO

4 Pages

-

ODAC® 33TRIO

4 Pages

-

ODAC® 63TRIO

4 Pages

-

ODAC® 14XY

4 Pages

-

ODAC® 18XY Micro

4 Pages

-

PREHEATER WST8/16/25

4 Pages

-

CELLMASTER®

4 Pages

-

PROFILEMASTER SPS 800

4 Pages

-

ODAC-USYS

6 Pages

-

ZUMBACH Electronic AG - General

32 Pages

-

CAPAC® HS

4 Pages

-

ODEX® 10

4 Pages

-

RAYEX® D XT

6 Pages

-

RAYEX® S

4 Pages

-

SIMAC® 40/70/120

2 Pages

-

LSV 1100 / 2100

2 Pages

-

PROFILEMASTER® PMM Series

4 Pages

-

USYS Touch

4 Pages

-

USYS IPCe

6 Pages

-

USYS 200

4 Pages

-

ODAC® 110XY

4 Pages

-

STEELMASTER SMR 230-400

6 Pages

-

ODAC® 550

4 Pages

-

ODAC® 310

4 Pages

-

ODAC® 230

4 Pages

-

ODAC® 160

4 Pages

-

ODAC® 100

4 Pages

-

ODAC® 60J

4 Pages

-

ODAC® 113TRIO

4 Pages

-

VISU-Touch

1 Pages

-

USYS 20

4 Pages

-

CALIBRATOR SP 40A

1 Pages

-

DVO 2

2 Pages

-

DVW 1

2 Pages

-

MSD 50 /100 /200

4 Pages

-

SPARKTESTER AST

4 Pages

-

STEELMASTER SMO

6 Pages

-

STEELMASTER SMS

6 Pages

-

STEELMASTER SMR

6 Pages

-

AUTAC 300

2 Pages

-

ECOGAUGE

4 Pages