Catalog excerpts

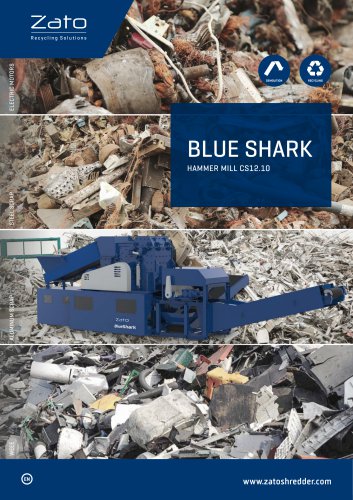

BLUE SHARK HAMMERMILLS

Open the catalog to page 1

HAMMERMILLS Blue Shark With Blue Shark series, we offer on the market an entire line of Hammermills designed for metal scrap shredding. Through a continuous process of product development, our shredding plants combine technical innovation and engineering excellent. Hammermills are available from 420 to 3,000 hp drive power and from 1,200 to 2,600 mm rotor diameters, they are designed to process volumes of scrap metals up to 15,000 tons per month range. Considering the actual market situation, where the over-capability of mega-shredder is applying a strong pressure on the profitability of...

Open the catalog to page 2

Applications Blue Shark offers the most efficient solution in shredding: • ELV: pre-cut / entire / baled • sorted domestic light scrap • white goods / household appliance • aluminum scrap, sheets and profiles • UBC, • brass, copper • WEEE electrical and electronic equipment • electric engines • waste ash from incineration plants • construction and demolition materials All the lines of Blue Shark Hammermills are designed to meet the latest environment regulations and can be applied both in scrap yard and steel works and foundries.

Open the catalog to page 3

All Hammermills’ manufactures suggest installing a pre-shredder upstream the Hammermill, as an essential tool to check on feeding speed, ensuring a smooth flow of processed material into the Hammermills and a higher density outproduct. We have developed an integrated solution, combining our Blue Devil Pre-shredder and Twin-Shaft Shredder GF series with our Blue Shark Hammermill: this ensures a greater efficiency, better output product and faster production, maintaining the Hammermill functionality and its duration. We offer on the market reliable solutions to the entire scrap recycling...

Open the catalog to page 4

Technical benefits that make Zato Hammermills Blue Shark series technology unique • Erection of the Hammermill in 3 weeks: The supporting structure of the Hammermill is completely pre-assembled in-house, before erecting it at the Customer premises. This feature allows an optimal checkup and to test entirely the functionality of the components and ensures a quicker erection then the traditional on-site erection, since it is possible to reduce unforeseen events. Moreover, this procedure allows the Customer to keep the costs of production of civil works under control. • Minimization of civil...

Open the catalog to page 5

• Hydraulic coupling: A hydraulic coupling made exclusively by us allows to gradually accelerate driven machines, limit torque, provide load sharing, and dampen torsional vibrations. In this way, the drive system is protected, even under extreme operating conditions and it is a safer protection for the engine. • 2 different system of feeding: Pushing Feeder (FP series); Infeed Conveyor & Roll (CS series).

Open the catalog to page 6

TECHNICAL DATA FP SERIES feeding pusher

Open the catalog to page 7

BLUE SHARK FP series The Blue Shark FP series hammermill’s greatest uniqueness is that the scrap is loaded into a feeding hopper, that, whilst containing the material provision, is also an extra impediment from projectiles expulsion coming from the shredding chamber. A hydraulic pushing feeder system allows an automatically controlled feeding of the hammermill avoiding all problems of overfeeding.

Open the catalog to page 8

BLUE SHARK CS series Hammermill Blue Shark CS series is characterized by the feeding system with conveyor and roll. Zato Blue Rex infeed conveyor is a heavy-duty conveyor engineered to withstand heavy shocks and impact loads. The loading area is a massive construction and thick steel plates sidewalls are disposed along the belt length. Provided with labyrinth seals to prevent lateral spillage and eliminate chain damage. All rollers and rails are manufactured from hardened steel alloy in order to reduce wear and ensure prolonged operational life. Being able to design the conveyor with a...

Open the catalog to page 9

Added Value INPUT MATERIALS INPUT MATERIALS Electric motors

Open the catalog to page 10

OUTPUT MATERIALS OUTPUT MATERIALS

Open the catalog to page 11

Zato srl Via Campi Grandi, 23 25080 Prevalle (BS) - Italy Tel. +39 030 6461800 Fax +39 030 6801897 e-mail info@zato.it

Open the catalog to page 12All ZATO srl Unipersonale catalogs and technical brochures

-

BLUE DEVIL

4 Pages

-

DYNAMITE ROTATING PULVERISER

4 Pages

-

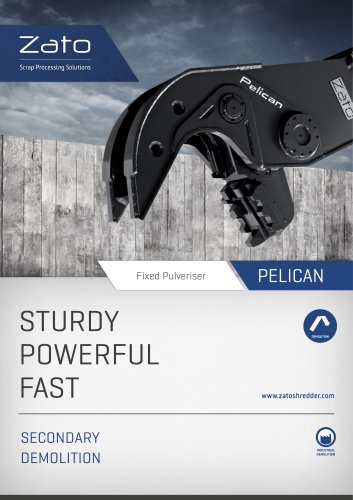

PELICAN

4 Pages

-

BLUE MARLIN

2 Pages

-

CAYMAN RAIL BREAKER

4 Pages

-

CAYMAN DEMOLITION SHEAR

6 Pages

-

BLUE SHARK 12-10 CS

2 Pages