Catalog excerpts

NJEX® Odorant Injection System Models 6300 and 6302 NJEX 6300 and 6302 odorant injection systems inject precise amounts of liquid odorant into cubic feet or meters, of gas that flows down a pipeline to ensure detectability. Ideal for lower flow applications, these proven systems provide proportional-to-flow odorant injection, onboard metering of the odorant injected, system monitoring and alarm notification. Additionally the system will document and verify the performance of each system component, parameter changes, alarms and injection rates. Available in a single or dual-unit configuration, the systems are capable of accurately injecting up to 6.7 liters/day (1.76 gallons/day). Patented, pneumatically-actuated, positive-displacement plunger pump 6.7 liters/day (1.76 gallons/day) maximum odorant output Versatile, electronic controller for proportional-to-flow or time-based injection Real-time system monitoring and alarm notifications Remote communication via ModBus or Sentry4 Software Intrinsically safe electronics Single or Dual Configuration to meet application requirements Weatherproof enclosure for protection from the elements. Specifications Maximum odorant output Maximum operating pressure Operating temperature range Power supply Standard SPS-12 solar panel Optional LPS 120/240 volt, 50/60 Hz AC charger Battery reserve Gas flow rate input signal At temperatures below 0°C (32°F) conditioning of the actuation gas supply may be required. © 2015 Accudyne Industries. All rights

Open the catalog to page 1

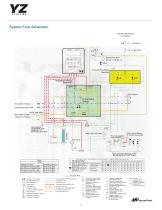

an Accudyne Industries brand System Flow Schematic Table 1 6300 Pipeline Pressure 100-200 psi (6.89-13.8 Bar) 200-500 psi (13.89-34.5 Bar) 500-900 psi (34.5-62.1 Bar) 900-1400 psi (62.1-96.5 Bar) © 2015 Accudyne Industries. All rights Reserved.

Open the catalog to page 2All YZ Systems catalogs and technical brochures

-

NJEX 7300G

129 Pages

-

Cyclone 4400

36 Pages

-

njex-6300-datasheet

129 Pages

-

YZ Connect

1 Pages

-

Crude Oil Sampling Systems

2 Pages

-

Odorization Systems

8 Pages