Catalog excerpts

• The products within this catalog era defined as industrial robots per Japan's Industrial Safety & Health Ordinance. 0 The photographs appearing in this catalog were taken without safety enclosures and other safety devices end equipment required by the aforementioned ordinance, in order to more clearly illustrate products. 9 Before using the products described in this catalog, please carefully read all instruction manuals and other documentation provided, to ensure proper use. Yushin, through all of our business activities and the application of earth-friendly, ergonomic technologies, promotes a healthy coexistence with the planet. * The content of this catalog is subject to change without notice, for improvement purposes. YUSHIN PRECISION EQUIPMENT COt,LTDt 555 Kuzetonoshiro-cho, Minami-ku, Kyoto 601-8205 JAPAN LUSHkN TEL 075-933-9555 FAX 075-934-4033 Yushin FRA series High End Take-out Robot YUSHIN PRECISION EQUIPMENT CO., LTD.

Open the catalog to page 1

Plastic Injection Molding today has given today's world the opportunity and benefits for innovative technology solutions and has continued to make better products with higher speed and quality. Take-out robots are crucial tools for manufacturing quality products with high speed precision in the plastic injection molding industry. Like any other industry, the plastic injection molding industry continues to face its own challenges: the difficulty of molding intricate parts, high-mix, short-run production, and factory floor hazards. Our ultimate goal was to create a robot that directly...

Open the catalog to page 2

High Precision Take-out control Vibration Control Results in Shorter Timers A take-out robot varies its arm length as required by application. Exchanging a robot's end-of-arm tool alters the mass of the robot's load. To operate with high precision regardless of the arm position or end-of-arm tool, a robot must be aware of the degree of its own vibration. The FRA senses its own vibrations and eliminates them automatically. Our goal was to deliver peace of mind for high-precision applications such as insert molding, which demand repeatability. The FRA is equipped with the world's most...

Open the catalog to page 3

Increased Productivity yushiniot Equip even one FRA series robot to change your facility into an Intelligent Factory INTU® LINE Gaining Full Knowledge of your Production Floor Status Monitoring production status was always a troublesome, expensive endeavor, requiring investment in infrastructure, expertise in networks and security, or even hiring a system integrator. "INTU LINE," however, is designed to enlighten simply by activating loT service, with zero initial investment needed for installing systems or LAN cables in your facility. INTU LINE operates completely outside of your company...

Open the catalog to page 4

UiNTir Check your Robot's Status LINE with Ease - Any Time, Any Place Check Production Status Whenever & Wherever You Choose Check production counts, cycle times, etc. on your mobile device or PC. INTU LINE enables users to collect data without relying on people's handwritten daily reports or gathering data from molding machine memory. Collects a wide range of info on one screen, with easy controls and quick access to detailed data. patent pending Decrease Downtime Monitor robot operations via the cloud. INTU LINE connects directly with Yushin's Al trouble diagnostics system, to find...

Open the catalog to page 5

Global Standard safety Greater Ease of Use comfor In high-mix, short-run production, the need for meticulous robot teaching is greater than ever. Fortunately, the FRA controller was built to please anyone who has wanted to concentrate on robot teaching without constant distractions from a clunky user interface. The FRA's controller and software were shaped by the unending pursuit of ever simpler, ever more effective Safety must be the absolute highest priority of any production facility. Yushin built the FRA in strict accord with this belief, incorporating international safety standards...

Open the catalog to page 6

"High-mix, Short-run Production" Yushin knows the importance of providing our customers with the l| 1 ji versatile equipment needed to mold high value-added products. Designing robots with the ability to perform many operations beyond just pick and place makes integration with downstream equipment an easy task. Servo Wrist Unit patent pending End-of-arm units which add servo-powered flip and rotation axes, allowing the robot to rotate end-of-arm-tools vertically or horizontally as needed. Servo Wrist Units greatly enhance automation and production efficiency. Axes Controlled Up to 50%...

Open the catalog to page 7

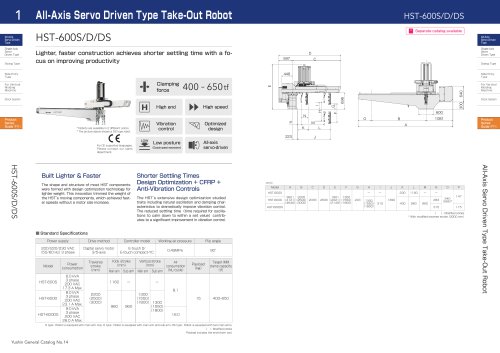

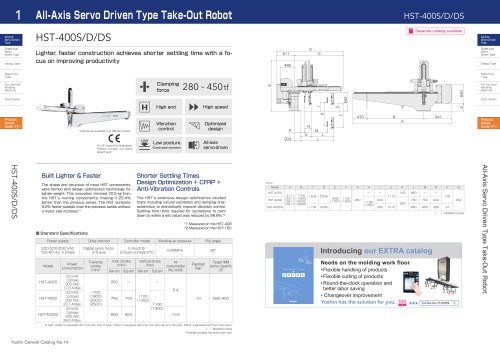

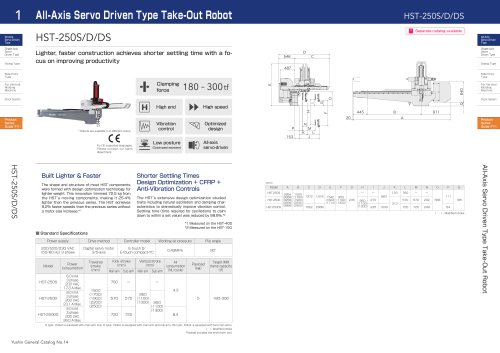

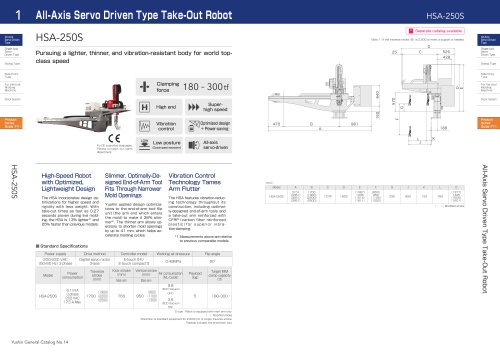

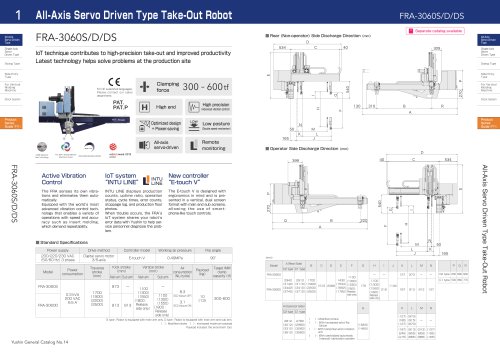

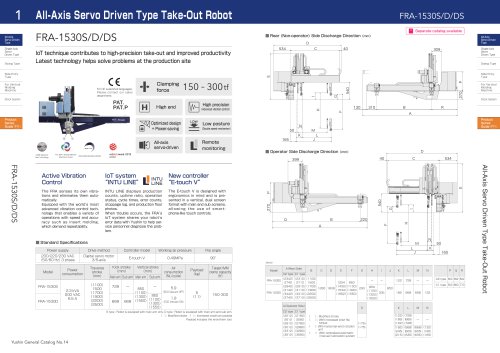

Payload includes weight of end-of-arm tool < ): Extended traverse stroke [ ]: Extended vertical stroke < >: Increased maximum payload A (Operator Discharge Direction) < )With increased wrist flip torque { } With horizontal wrist rotation unit ( >With centralized manual lubrication system * For more detail on C2 and Cl safety specifications, please see p. 10 * For more detail on C2 and Cl safety specifications, please see p. 10

Open the catalog to page 8