Catalog excerpts

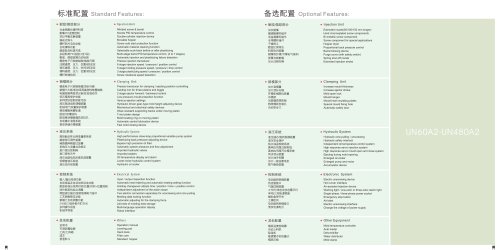

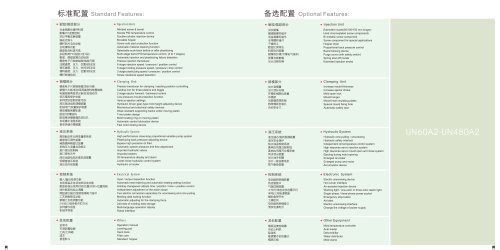

te)ftiBB Standard Features: • Injection Unit Nitrided screw & barrel Nozzle PID temperature control Double-cylinder injection device Movable hopper Screw cold start protection function Automatic material cleaning function Selectable suck-back before or after plasticizing Multi-stage barrel PID temperature control. (4 to 7 stages) Automatic injection and plasticizing failure detection Precise injection transducer 6 stage injection speed / pressure / position control 5 stage holding pressure speed / pressure / time control 3 stage plasticizing speed / pressure / position control Screw rotational speed detection • Clamping Unit Precise transducer for clamping / ejecting position controlling Casting iron for three platens and toggle 2 stage ejector forward / backward control Low pressure mould protection function Various ejection settings Hydraulic driven gear-type mold height adjusting device Mechanical and electrical safety devices Wear-resistant supporting tracks under moving platen T-slot platen design Mold locating ring on moving platen Automatic central lubrication device Fast mold closing device • Hydraulic System High performance close-loop proportional variable pump system Plasticizing back pressure adjusting device Bypass high precision oil filter Automatic system pressure and flow adjustment Imported hydraulic valves Imported sealers Oil temperature display and alarm Lower-noise hydraulic control system • Electrical System Input / output inspection function Automatic heat retaining and automatic heating setting function Holding changeover adopts time / position / time + position control Independent adjustment of the action slope Two electric connectors separately for unscrewing and core pulling Molding data locking function Automatic adjusting for the clamping force 240 sets of molding data storage Multi-language operation display Robot interface SflfcES • Others XMJXM& Hand tools Standard hopper Optional Features: Injection Unit Hard chromeplated screw components Bi-metallic screw component Screw component for special applications Hopper dryer Proportional back pressure control Barrel blowing device Purge cover (with safety switch) Spring shut-off nozzle Extended injection stroke iUj\^tMM Increase mould thickness iW^MWfj^S. Increase ejector stroke JF«*l«P8fi3e« Mold open lock JP^SWIfflKtft Mould heat insulating plates iffBMS^SSifL Special mould fixing hole § 3fj$±n Automatic safety door Hydraulic System Hydraulic core-pulling / unscrewing Hydraulic safety interlock Independent oil temperature control system High response servo injection system High response servo mould open and close system Ejecting during mold opening Enlarged pump and motor Accumulator device • Electronic System Electric unscrewing device Air-assisted injection device Working light / one-color or three-color alarm light Single-phase / three-phase power socket Emergency stop button Electric unscrewing interface Change the voltage of power supply • SffeKfi • Other Equipment Mold temperature controller HfcSfll Dehumidifier !Sare>£SPaE*it Water distributor

Open the catalog to page 1All Yizumi catalogs and technical brochures

-

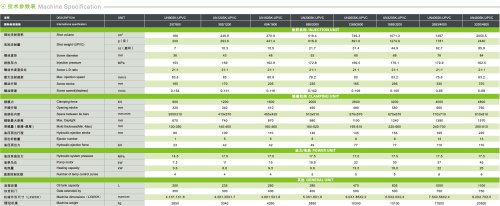

DP specification

7 Pages

-

upvc specification

1 Pages

-

FE specifications

2 Pages

-

A2 features

1 Pages