Catalog excerpts

HIGH-END EQUIPMENT Preform Production Equipment (U Product Description MCVD is the abbreviation of Modified Chemical Vapor Deposition, which is translated as improved chemical vapor deposition. The production method of prefabricated rod was first proposed by Bell Laboratories in the United States and Southampton University in the early 1970s, and invented by Bell Laboratories in the United States in 1973. In view of the strong flexibility of MCVD equipment in preparing different kinds of preforms, it has become one of the four main methods to produce high-quality preforms for communication optical fibers, and has a wide range of applications in the field of manufacturing special optical fiber preforms for sensing and laser. MCVD method can deposit higher purity silicon dioxide (SiCh) on the inner wall of quartz tube (commonly called liner) with high quality (high purity, low moisture and low impurities), Other high-purity substances that can change the refractive index or vitreous viscosity, such as germanium dioxide (Ge02), phosphorus pentoxide (P2O5), silicon oxide fluoride (SiOrsF), etc., are doped to form cores and cladding with different refractive indices, so as to achieve total reflection, low loss and high capacity when optical signals propagate in the fiber core. 2$: Product Features • MCVD technology can be used to produce a variety of products Communication fiber (SM, DSF, NZ-DSF, GI multimode, step index single mode fiber, etc.); Sensor fiber and amplifier fiber with different components and materials; Other special optical fibers with wide applications. * MCVD rod making system has precise parametric process setting; • The modular structure design adopted by MCVD rod making system can adapt to the manufacturing requirements of various silicon-based fiber preforms; • MCVD rod making system has simple equipment, low investment cost and wide application range; • MCVD rod making system can provide precise heating bubbling chamber and process line for preform production; • All gases in MCVD rod making system are controlled by local particle filtration (0.003 micron) and pressure regulation, and dual-mass flow controller is adopted according to the latest MFCs digital technical standard to improve the control accuracy of its process line; • MCVD lathe provides thermal protection cover: to ensure thermal radiation, eliminate hot air, safety in case of large leakage and mechanical failure, ensure the cleanliness of the workshop and protect the health of workers; * The MCVD rod making system uses humanized man-machine operation interface, which is simple and friendly to operate and can be customized according to customer requirements; • MCVD bar making system can provide lathes of different lengths: 2100 to 3000mm; • MCVD lathes can provide a variety of quartz and stainless steel burners of different sizes and models. @ Product Specification

Open the catalog to page 1All Yangtze Optical Electronic Company Ltd. catalogs and technical brochures

-

FCA-5-T Heat-cured Adhesive

1 Pages

-

Adhesive for FOG Coil

1 Pages

-

Fiber Cleanging Machine

1 Pages

-

Fiber Coloring Machine

1 Pages

-

Pigtail Fixed-length Cutter

1 Pages

-

Sectional Fiber Marker

1 Pages

-

Fiber Bragg Grating Etcher

1 Pages

-

Compact Fiber Rewinder

1 Pages

-

Fiber Defect Detector

1 Pages

-

UV curing system

1 Pages

-

Fiber optic drawing frame

1 Pages

-

Custom optical cable

1 Pages

-

Air core optical cable

1 Pages

-

Optical beam splitter

1 Pages

-

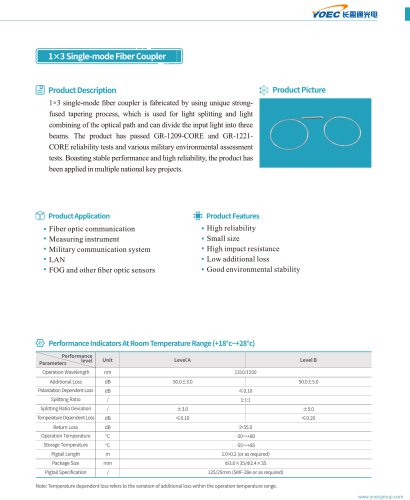

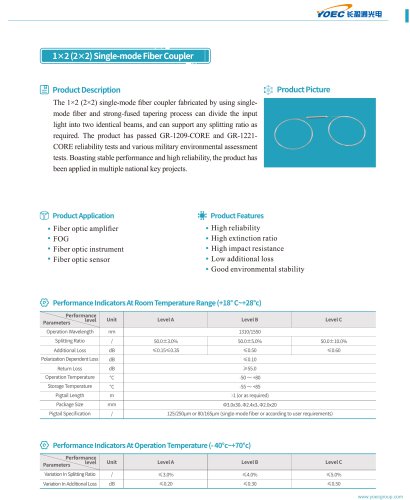

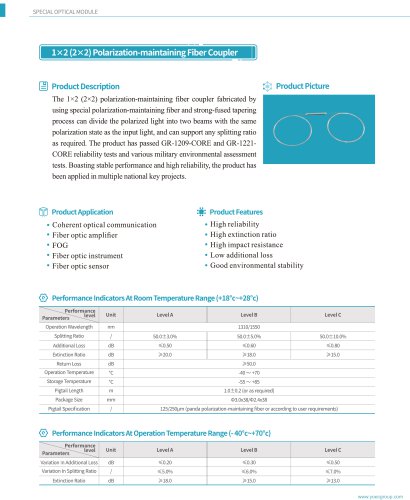

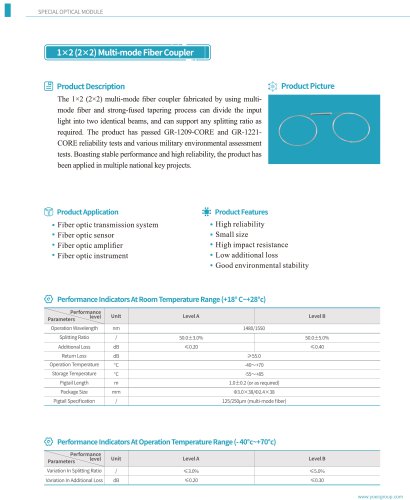

Fiber optic coupler

1 Pages

-

water-sensitive coil

1 Pages

-

Fiber optic coil

1 Pages

-

fiber optic coil

1 Pages

-

Communication Delay Coil

1 Pages

-

Ase Module

1 Pages

-

98-Series FOG Optical Module

1 Pages

-

70-Series FOG Optical Module

1 Pages

-

50-Series FOG Optical Module

1 Pages

-

42-Series FOG Optical Module

1 Pages

-

37-Series FOG Optical Module

1 Pages

-

32-series FOG optical module

1 Pages

Archived catalogs

-

Optical Fiber Arranger

1 Pages

-

Multi-core optical cable

1 Pages