Website:

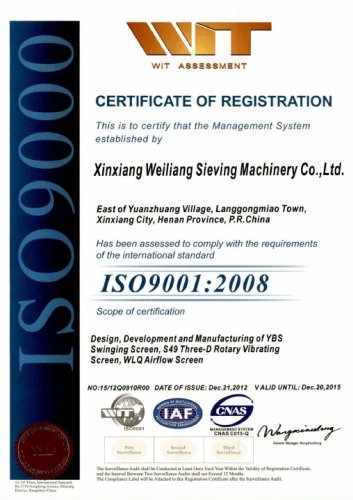

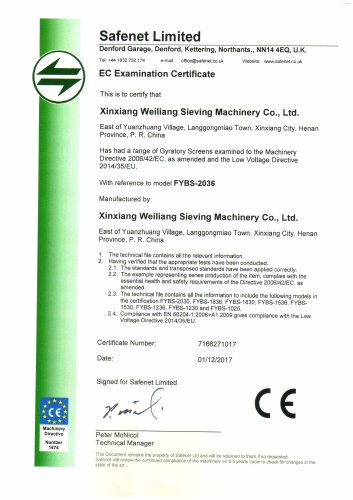

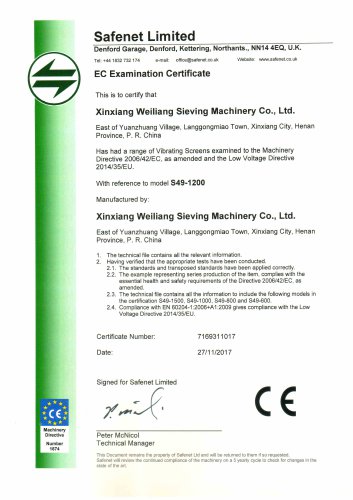

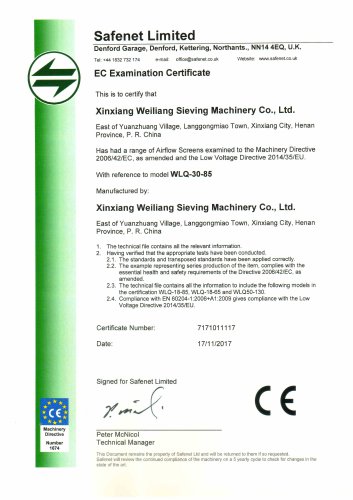

Xinxiang Weiliang Sieving Machinery

Website:

Xinxiang Weiliang Sieving Machinery

Catalog excerpts

Rotary brush cleaning Bouncing ball cleaning Ultrasonic cleaning Modular design and process optimization 1. Basic gyratory motion is similar to artificial screening. Eccentricity is adjustable from 25 to 40mm, low-speed V-belt drive is adjustable from 120 to 360rpm 2. Each products’ dwell time can be adjusted by the radial of swing screen and the angle towards the direction of drive axis. The process is repeated in each screen deck. 3. Therefore, establishing the horizontal and throwing three-dimensional rolling movement, materials are evenly dispersed on the entire screen surface from the center to the outer edge, and thus spread towards the axis by spiral movement. Small particles finished screening process. 4. The horizontal and vertical acceleration are increased with the movement of the particles, and then the particles which are close to wire mesh size will be successfully separated; The larger particles are transported to the exit, the flow can be controlled by a regulated oriented device at the exit, the oriented device is another factor which controls the dwell time of the materials. 5. The process repeated on each screen deck. » Pneumntic Device: Rotary brush cleaning device depend on the brushs rotating under the wire mesh, it’ s application for ball shape, crystal and brittle materials, the device support arms are drive by speed reducer and installed on the machine base. Placed under wire mesh and on the perforated plate, bouncing balls efficiently accomplish the cleaning operations by irregularly striking the wire mesh, which is widely applied. Ultrasonic cleaning is suitable for fine material processing. The high- frequency vibration caused by the ultrasonic generator not only effectively solves the blocking phenomena, but also greatly improves the production capacity. What’s more, Weiliang provides various kinds of ultrasonic devices to meet different screening Fine material Same mesh# on two decks, screening accuracy. Coarse material Fine material Double decks twice screening Fine’material Coarse'material Three decks screening Same mesh# on three decks, in order to achieve the highest screening efficiency. Weiliang special designed pneumatic devices make the constant replacement of materials and screen mesh specification more convenient. What’ s more, there is no need of any other hoisting equipment to accomplish this replacing process. Overall Diagram » Application: Chemical industry, food, spices, plastics, mining, pharmacy, wood, plywood, metallurgy, rubber, feed, fertilizer, sugar, salt, recycling industry etc. » Technical Parameters: Screening control chart Coarse material- Material: Metal silicon powder (2)and(3) deck with same mesh#, improve output and screening accuracy. Medium material Fine material Double decks with preliminary screening Double output screening Two layers of same screen mesh, each layer takes 50% feed capcaity Remark : instructions of cleaning codeQ)Bouncing ball cleaning(2)Rotary brush cleaning®Ultrasonic cleaning YBS Swing (Tumbler) Screen Swing screen is special designed to meet the requirements for large output and high precision, which effectively simulates the artificial screening principles, and suitable for all fine and superfine powder, as well as the unmanageable materials. » Characteristics^^M^^M Up to 5 times output per unit area; Accurate to 6 Level separation, screening efficiency is as high as 90% -95%; When using the silicone rubber balls, ultrasonic and rotary brush mesh-cleaning device system, the wire hole will not be blocked. Confined cleaning dust, safe operation; the acceleration is 4.5 times lower than vibrating screen, screen accessories increases the life expectancy and reduces maintenance; Noise <75 dB, ground-based dynamic load is low.

Open the catalog to page 1All Xinxiang Weiliang Sieving Machinery catalogs and technical brochures

-

Weiliang vibrating screener

1 Pages