Catalog excerpts

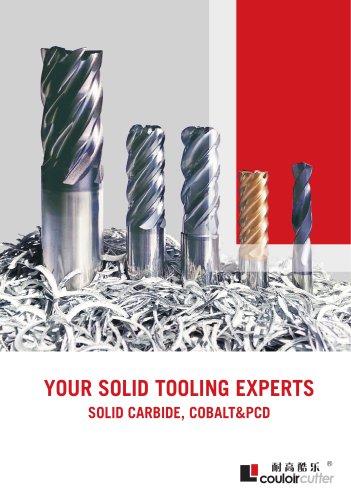

YOUR SOLID TOOLING EXPERTS SOLID CARBIDE, COBALT&PCD

Open the catalog to page 1

YOUR SOLID TOOLING EXPERTS A REQUIREMENT FOR US & A PROMISE TO OUR CLIENTS In the cutting tool industry , quality is always sought but not always achieved. No one in the industry pays more attention to consistency and quality than Couloir Cutter. It all begins in our dedicated engineering , manufacturing and test facilities and Our in-plant machining and metallurgical laboratories are just a few of the resources to help keep our promise.

Open the catalog to page 2

USA, France, Malaysia, China GRAND CANYON Golden Snake

Open the catalog to page 7

CFRP PCD CFRP ROUTERS

Open the catalog to page 8

END MILL GRAND CANYON 2.0 GRAND CANYON 2.0 M-STYLE M CASE STUDY GRAND CANYON 2.0 P-STYLE P ELITE SERIES HIGH PERFORMANCE 2 VFP&VFP FOR TITANIUM AND STAINLESS ELITE SERIES FOR ALUMINIUM

Open the catalog to page 9

ELITE SERIES FOR HARDEN STEEL

Open the catalog to page 10

ELITE SERIES FOR STAINLESS, STEEL ELITE SERIES DIAMOND COATED DIAN230S DIAN230B ELITE SERIES FOR CFRP CFRP CFRP

Open the catalog to page 11

ELITE SERIES FOR MICRO DECIMAL

Open the catalog to page 12

CHAMFER MILL CHAMFER MILL DRILL GOLDEN SNAKE GOLDEN SNAKE TRIPLE FLUTES GTA GOLDEN SNAKE P-STYLE GP GOLDEN SNAKE P-STYLE GP GP Series 3D GOLDEN SNAKE S-STYLE GS GS Series 3D GOLDEN SNAKE F-STYLE GF GOLDEN SNAKE F-STYLE GF

Open the catalog to page 13

GOLDEN SNAKE MQL DEPTH DRILL GOLDEN SNAKE DEPTH GENERAL PURPOSE DRILL MICRO DECIMAL CM Series

Open the catalog to page 14

WORKPIECE MATERIAL CLASSIFICATION couloir material group CMG 、 ISO Strutural steel Ordinary carbon steels with low to medium carbon content (<0.5%C) ( 0.5%) Carbon steels with high carbon content(>0.5%) ( 0.5%) Ordinary low-alloy steels Ferritic and martensitic stainless steels Free-cutting steels Very soft carbon steels Purely ferritic steels Normal tool steels Harder steels for toughening Martensitic stainless steels Difficult tool steels High-alloy steels with high hardness Martensitic stainless steels Difficult high-strength steels with 42 to 56 HRC hardness HRC42-56 A128 Grade A...

Open the catalog to page 15

END MILL CODE KEY COULOIR Product Family Tool shape PRODUCT FAMILY COULOIR code Overall length GCM540 160 D 20 092 C040 X .3010 Cutting diameter Length of cut Chamfer Coating Example: GCM=Grand Canyon M Style 5=5 Flutes 40=40 CUTTING DIAMETER Example: 160=16mm TOOL SHAPE (Dc=dmm) OVERALL LENGTH Example: 20=2*Cutting Diameter 05=0.5*Cutting Diameter Corner radius S=SQUARE END B=BALL NOSE R=RADIUS C=CHAMFER 45 For example: R075=0.75MM Radius DESCRIPTION COATING Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar A...

Open the catalog to page 17

DRILL CODE KEY COULOIR Product Family Tool shape PRODUCT FAMILY Overall length COULOIR code Example: GS=Golden Snake S Series CUTTING DIAMETER Example: 0300=3mm DIAMETER OF SHANK TOOL SHAPE (Dc=dmm) OVERALL LENGTH Example: 062=62MM DESCRIPTION COATING Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar Microkevlar A ALCrN B ALTIN C Nano TiALN D/L TiALN E Multi ALCrN F TiN G Blueshield H TiALN-based K TiB2 N CVD Diamond P Nano ALTIN Example: E=Microkevlar E=Multi ALCrN

Open the catalog to page 18

TECHNICAL DATA SYMBOL KEY TOOL MATERIAL - SUBSTRATE 8%

Open the catalog to page 19

TOOL SELECTION GUIDE We can help you increase your productivity, enhance your performance and reduce your costs with our wide range of tools for every application. Every job needs a different tool, and we offer suggestions on tool selection based on types and material. Please take a look and decide which tool best suits your needs. , , PROVIDED SOLUTIONS FOR ANY APPLICATION END MILL Grand Canyon Series Elite Series C Series Economy Golden Snake C Series

Open the catalog to page 20

APPLICATION RAMGE 、 2.0 GRAND CANYON CRABIDE END MILL A ELITE A SERIES CARBIDE END MILL HSU ELITE HSU SERIES CARBIDE END MILL 。 。 Extotic materials like stainless,Nickel alloys and Titanium.Heavy and Silent cutting.Variable Leads,Couloir's patent. 、 、 。 Specially designed for aviation and aerospace purposes.For Titanium, stainless heavy cutting rough and self-finish. 、 。 Specially designed for every aluminium alloy cutting. HRC50~HRC70 、 、 。 High Harden Steels HRC 50 to HRC 70, High Spdde Machining.DRY Cutting. 。 High feed machining for every material. SN EILTE SN SERIES CARBIDE END MILL S...

Open the catalog to page 21

APPLICATION RAMGE 。 For multiple composite material milling. CFRP、GFRP 。 For aerospace material millingCFRP、 GFRP. GENERAL PURPOSES 。 General use micro decimal end mill. 。 Conventional general purposes end mill. CFRP ELITE CFRP SERIES END MICRO DECIMAL END MILL COATDE GENERAL PURPOSES END MILL. C SERIES AND ESERIES CHAMFER MILL General purposes chamfer and de-burr end

Open the catalog to page 22

APPLICATION RAMGE 。 、 、 。 Castiron, steel and alloy steel high feed drilling.3D,5D,with cooling. 、 。 HRc30~HRc50, , , , / 。 Castiron,steel,alloy steel and easy-cut, stainless drilling.HRc30~50.3D,5D,8D with cooling or without. GOLDEN SNAKE-T STYLE FOR HIGH FEED TRIPLE FLUTES P GOLDEN SNAKE-P STYLE FOR GENERAL PURPOSES DRILLS S GOLDEN SNAKE-S TYPLE FOR TOUGH MATERIAL F GOLDEN SNAKE -F STYLE MQL GOLDEN SNAKE-MQL STYLE FOR DEEP HOLLE 、 。 , , 。 Tough material like stainless steel, Nickel alloy and titanium.3D,5D with cooling or without. 180 , 。 Flat drill print,for cross hole,inclined hole, or...

Open the catalog to page 23

、 GRAND CANYON 2.0 M-STYLE High Efficiency Machining with Titanium&Inconel Alloys Excellent tools for aerospace industry & power generation For roughing,semi-finishing and also finishing difficult-to-machine materials COULOIR advanced coating technology “Microkevlar”makes better Resistance against wear Double core design reduces tool deflection when finishing and improves chipping when roughing , , , Grand Canyon 2.0 M-style "Offers a high performance metal removal rate with secured and Chatter-free machining in semi-finishing and finishing." Excellent chip evacuation Double core geometry...

Open the catalog to page 26

、 GRAND CANYON 2.0 M-STYLE CASE STUDY-1 Cutting Edges 70 Total Milling Length : 17.25m Total Milling Length : 16.11m Total Milling Length : 16.04m Cutting Length(m) Cutting Conditions Feed Slotting Cutting Depth - DIN: Ti6AI4V (Titanium) Coolant - WR: 3.7165.1 Overhang Φ12 Φ12 26 83 R1 Machine 1591 rev./min Milling Method Work Material Size RPM 254 mm/min 12mm (Axial Depth) Wet Cut 36 mm Machining Center CASE STUDY-2 Cutting Edges Cutting Length(m) Milling Method Work Material Size RPM Cutting Conditions Feed Down & Side Cutting Axial Depth - DIN: Ti6AI4V (Titanium) Radial Depth - WR:...

Open the catalog to page 27All XIAN COULOIR CUTTER CO. catalogs and technical brochures

-

GT1803E

226 Pages

-

YOUR SOLID TOOLING EXPERTS

346 Pages

-

HSS-PM DRILL

10 Pages