Catalog excerpts

XI'AN YUNYI INSTRUMENT CO.,LTD. 1.Pressure Transmi�er 4.Dead Weight Tester 7.Temperature Transmi�er 2.Pressure Gauge 5. Level Transmi�er 8.Density Meter 3.Pressure Calibrator 6.Flow Transmi�er https://www.yunyiinstrume

Open the catalog to page 1

Orifice flowmeter This measurement method is based on the law of conservation of energy and mobility continuity equation. The relationship between differential pressure and flow can be determined by the following formula: Principle As fluid flow full of a pipeline flow through the throttle device in the pipeline, the flow beam will be partially contracted in the throttle device so that the flow velocity increase, static pressure decrease, and then Static pressure difference will be formed in front and back of the throttle device. The greater flow velocity of fluid is, the greater...

Open the catalog to page 2

1. Corner taps. (Figure 1) 2. Flange taps. (Figure 2) conditions change, will occur. Therefore, to allow, (flow coefficient for the constant) the measurement can be corrected with the following formula. 1. Changes of Pressure and temperature unit) Q1—reading flow (volume unit)(volume unit) R1—the designed weight of flow material R2—the actual weight flow material 2. Change of Pipe diameter 3. G2= G1α2ε2 /α1ε1 α 1 — The original design flow coefficient α 2 — The actual design flow coefficient ε 1 — The original design inflation coefficient ε 2—The actual design inflation coefficient 4....

Open the catalog to page 3

axis and gasket concentric, the misalignment should not exceed 0.002D / β. After clamping the gasket should not be into the internal pipeline. 2. Positive and negative direction of the orifice, upstream flange taps and downstream flange taps should be coincident with the direction of the dielectric flow. Position of the pressure tapping is determined by the flow characteristics and the transmitter installation status. 3. Connecting the pipeline to the throttle device, the non-orthogonality of the welding section and the pipe axis can not exceed 1 º. After the internal welding seam should be...

Open the catalog to page 4

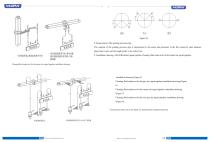

Figure IV 8. Requirement of the guiding pressure pipe. The material of the guiding pressure pipe is determined by the nature and parameter of the flow material, inner diameter larger than 6 mm, and the length prefer to be within 16m. 9. Installation drawing of the differential signal pipeline Cleaning fluid under test for the liquid, the signal pipeline Cleaning fluid under test for the steam, the signal pipeline installation drawing installation drawing (Figure 5) Cleaning fluid under test for the gas, the signal pipeline installation drawing (Figure 6) Cleaning fluid under test for the...

Open the catalog to page 5

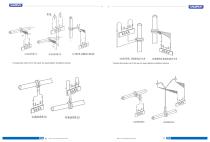

Cleaning fluid under test for the liquid, the signal pipeline installation drawing Cleaning fluid under test for the gas, the signal pipeline installation drawing

Open the catalog to page 6All Xi'an Yunyi Instrument Co. catalogs and technical brochures

-

K series

3 Pages

-

YX-2006B

2 Pages

-

XY-2002

1 Pages

-

YFM4800E

14 Pages

-

YD32

2 Pages

-

Temperature calibrator WT

2 Pages

-

Pt100 temperature sensor

3 Pages

-

Digital density meter JL-T

6 Pages

-

Process density sensor

8 Pages

-

Digital density meter YMF883

4 Pages

-

Digital density meter JL-YT

4 Pages

-

Digital density meter JL-LD

2 Pages

-

Digital density meter JL-SD

2 Pages

-

Digital density meter JL-GD

2 Pages

-

Portable pH meter K series

2 Pages

-

Leak calibrator XY-2006B

2 Pages

-

Deadweight tester JY

2 Pages

-

Pressure calibrator XY-2001A

2 Pages

-

Pressure calibrator YX-60

2 Pages

-

Leak calibrator YX-2001C

2 Pages

-

Dial pressure gauge YK-M4

2 Pages

-

Infrared flow meter YFM-4800

21 Pages

-

Mass flow meter YFU2000-B

4 Pages

-

Mass flow meter Coriolis

14 Pages

-

Mass flow meter MF4000

3 Pages

-

Mass flow meter

3 Pages

-

Vortex flow meter YFV

20 Pages

-

Ultrasonic flow meter YFU2000H

14 Pages

-

Turbine flow meter YFT

13 Pages

-

Mass flow meter YFV300

20 Pages

-

Mass flow meter YFT300D

13 Pages

-

Turbine flow meter

13 Pages

-

Mass flow meter MF5700

3 Pages

-

Liquids level gauge UHZ-10

1 Pages

-

Level measuring instrument

11 Pages

-

Liquids level gauge YLR68

12 Pages

-

Liquids level gauge

3 Pages

-

Radar level sensor

12 Pages

-

Diaphragm pressure switch

2 Pages

-

Digital pressure controller

2 Pages

-

YD31 series

4 Pages