Catalog excerpts

INNOVATIVE BOARD-LEVEL SHIELDING Acquired from W.L. Gore & Associates TECHNICAL SUMMARY XGR Technologies SnapShot EMI Shields are revolutionary, multi-cavity shields that solve many of the problems associated with today’s existing shielding technologies. The shields consist of a lightweight, metallized plastic material that is thermoformed to virtually any design. The shields are attached to your PCB via a patented attachment mechanism utilizing individual BGA solder spheres. The shields are metallized with tin on the outside surface only, resulting in narrower ground traces, reduced space between components, and reduced shield heights when compared to existing shielding solutions(no air gap needed). XGR SnapShot EMI Shields are multi-cavity, board evel EMI l shielding solution. The product installs after the SMT reflow process, allowing for easy component inspection or rework, and is readily removed by hand without damaging the board or resoldering. FEATURES AND BENEFITS • Superior shielding performance • ightweight, metallized plastic material L In addition to custom contoured design and manufacturing flexibility, XGR SnapShot EMI Shields have superior shielding performance when compared to perforated, soldered metal cans. • Easy BGA attachment mechanism • nstalls after SMT reflow and inspection I processes • Complete design flexibility • Easily removable by hand TYPICAL APPLICATIONS SNAPSHOT EMI SHIELDS TYPICAL PROPERTIES1 • Broadband data center routers Shield Material Property Metallization Adhesion Metallization Thickness Dielectric Strength • Commercial communication devices • Military handheld radios Shielding Effectiveness Surface Resistivity • Industrial barcode scanners Surface Resistivity • Mobile consumer electronics ROHS STATUS RoHS Material* Pass / Fail Hexavalent Chromium (Cr6) Content Bromine Compounds * GR Technologies declares that we do not intentionally add substances listed in X EU Directive 2011/65/EU (RoHS Recast). Vicat Softening Temp. B Solder Sphere Property Sphere-to-Sphere Spacing Sphere Diameter V alues are for reference only and are not inten

Open the catalog to page 1

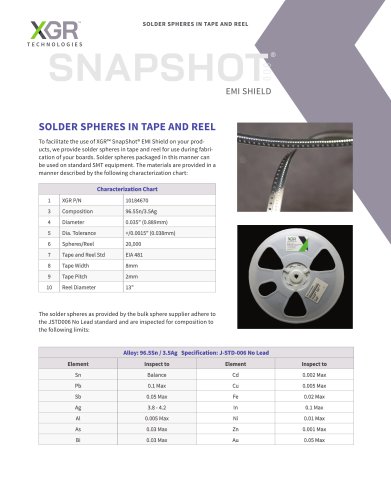

INNOVATIVE BOARD-LEVEL SHIELDING SOLDER SPHERE INSTALLATION There are different methods of installation currently available. Acquired from W.L. Gore & Associates DC RESISTANCE BETWEEN SOLDER SPHERE AND SHIELD PRE VS POST 5 DAY ALT AT 85°C, 85% RH Solder spheres can be supplied in accordance with the current ANSI/ EIA-481 standard compliant tape and-reel format to work seamlessly with existing SMT equipment. An alternative to tape-and-reel is to use a bulk feeder with your SMT equipment. This solution is less expensive than tape-and-reel. RELIABILITY TESTING The DC resistance across each...

Open the catalog to page 2