Catalog excerpts

EMI SHIELDING TECH NOLO GY REVOLUTIONARY BOARD LEVEL EMI SHIELDING FOR SUPERIOR PERFORMANCE AND TOTAL DESIGN FLEXIBILITY.

Open the catalog to page 1

Who’s Behind SnapShot? William Candy President | XGR Technologies SnapShot® was launched into the market by W.L. Gore & Associates in 2002 and has over 18 years of proven success in hundreds of applications in medical, military, industrial, aerospace and computing. XGR Technologies was founded in 2018 by one of the original SnapShot® inventors and former W.L. Gore & Associates engineer, Mr. William Candy. In 2018, Mr. Candy partnered with a group of technology investors and acquired all of the SnapShot manufacturing, intellectual property and business assets from W.L. Gore & Associates....

Open the catalog to page 2

Get a closer look at what makes SnapShot® EMI shielding so special SnapShot® EMI Shields are revolutionary, single or multi-cavity shields that answer many challenges associated with today’s existing shielding technologies. The light-weight, metallized plastic material is thermoformed to virtually any design and offers superior shielding performance compared to perforated or frame and lid style metal cans

Open the catalog to page 3

A Peek Inside SnapShot's Superior Build Lightweight metallized plastic and revolutionary "snap-in-place" set the SnapShot apart. | Metalized Plastic • Conductive outer surface (Tin) • Non-conductive inner surface (PEI) | Attaches by “snapping” over Solder Spheres • Manual or automated with the use of installation tooling • Creates strong electromechanical connection + SnapShot® EMI Shields Typical Properties Shield Material Property Metalization Adhesion Metalization Thickness Dielectric Strength Thickness Planar Shielding Surface Resistivity Vicat Softening Temp. B

Open the catalog to page 4

+ Design Flexibility Each application is custom designed to meet the unique size and shape requirements of the board layout. Shields are thermoformed to virtually any shape | Single or multi-cavity for high density board design | Multiple height profiles within a single shield | Low profile with zero clearance required between components and inner shield surface | With or without perforations | “Dog house” capable for superior shielding of board edge connectors + Extremely Rugged and Durable Proven to withstand shock, vibration, moisture, and aging, SnapShot is ideal for industrial and...

Open the catalog to page 5

+ Installs After Reflow Easy installation after the reflow process allows for unobstructed inspection and rework. | Removable and replaceable by hand without damage to the board and no need for resoldering | Easy BGA attachment mechanism using solder spheres as individual mechanical snap features | Allows for Automated Optical Inspection Solder Spheres attached during reflow SnapShot® Shield Attached after reflow + Very Lightweight Ideal for applications where grams matter. | Specialized thermoplastic material is extremely lightweight | Thin, non-ferrous engineered polymer is metallized...

Open the catalog to page 6

+ Superior Shielding Effectiveness | SnapShot® outperforms competitive options in shielding effectiveness from below 1 GHz to 12 GHz | Extremely consistent isolation across a wide frequency range | Non-conductive interior surface reduces electromagnetic coupling with circuit traces, minimizes overall volume, and eliminates shorting threats Relative Shielding Effectiveness of XGR SnapShot EMI Shields Versus Traditional Metal Cans (10 dB per Division

Open the catalog to page 7

MEDICAL ELECTRONICS NETWORK COMPUTING

Open the catalog to page 8

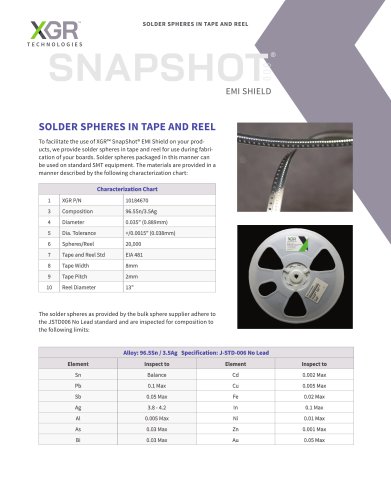

Complete the Perfect Shielding Package with Solder Spheres To facilitate the use of XGR SnapShot EMI Shield on your product, XGR is proud to provide solder spheres in tape and reel packaging. Solder spheres packaged in this manner can be used on standard SMT equipment, are RoHS and REACH compliant. Composition Diameter Tape Width Tape Pitch Reel Diameter

Open the catalog to page 9

Ready to get on board? For more information, to discuss your specific application needs, or to receive a free sample of our products, please get in touch with your Sales Representative or contact XGR Technologies directly. We’ll be happy to help you find a SnapShot® solution that solves your shielding challenges. 110 Executive Drive, Suite 1A Newark DE 19702 p: 1-302-669-9554 | f: 1-302-298-1504 | e: sales@xgrtec.com www.xgrtec.c

Open the catalog to page 10All XGR Technologies catalogs and technical brochures

-

XGR SnapShot Tech Summary

2 Pages