Website:

WOMA GmbH

Website:

WOMA GmbH

Group: Kärcher Group

Catalog excerpts

WOMA® HIGH-PRESSURE PUMPS Reliable and powerful plunger pumps from 250 – 3,000

Open the catalog to page 1

WATER AS A TOOL WOMA high-pressure plunger pumps are characterised by their solid construction and excellent workmanship. The diverse range of pumps offers the right high-pressure pump for almost every high-pressure application, especially in the field of high-pressure water jet technology. Among the numerous options available for WOMA pumps is the Twin-Concept. In the range of gearbox sizes 150 to 700, this concept allows a second pump of a smaller or equal size to be connected to the free end of the drive shaft. In addition, all pumps apart from the 3-series are available as ATEX versions...

Open the catalog to page 2

Content M-series (3,000 bar) with extremely high pressures. Z-series (1,500 bar) for industrial cleaning. Y-series (1,000 bar) for compact systems. 2-series (750 bar) for harsh environments. ARP-series (400 bar) for high flow rates and contaminated water. 3-series (250 bar) for cleaning and rinsing.

Open the catalog to page 3

M-SERIES (3,000 BAR) Power packs with extremely high pressures. In combination with the wide range of WOMA water tools, the M-series high- pressure plunger pump with its operating pressures of up to 3,000 bar is the right choice for cutting, dismantling or decoating work.

Open the catalog to page 4

The M-series offers a suitable high-pressure pump for applications requiring ultra-high-pressures. The range starts with the compact 70M with a required driving power of 45 kW through to the 500M pump, which demands a corresponding driving power of 402 kW. What all the pumps from the M-series have in common is extreme stability due to their premium quality materials in combination with accurate manufacturing and a well thought-out design. The robust carbide plungers are leaded in precise guide rings, cooled by the sealing water system, and protected against dirt or damage for a long service...

Open the catalog to page 5

TECHNICAL DATA Performance data 70M Pinion shaft 750 1/min 825 1/min Gear ratio 1.00 1.00

Open the catalog to page 6

Cleaning of ships and buoys The cleaning applications of ships and buoys in ultra-high-pressure water jetting are manifold. Starting with the simple surface cleaning, over to the removal of algae, shells and other deposits up to the paint removal – WOMA offers the suitable solution for each task. Concrete repair With the help of ultra-high-pressure technology, concrete can be removed quickly and safely. When concrete is removed using ultra-high-pressure water jets, it creates only very minimal vibrations in the construction. The steel reinforcement is exposed with accuracy, precision and...

Open the catalog to page 7

Z-SERIES (1,500 BAR) Power packs for industrial cleaning. Energy efficiency and resource protection are challenges in industrial cleaning and decoating that can be successfully mastered by the WOMA Z-series.

Open the catalog to page 8

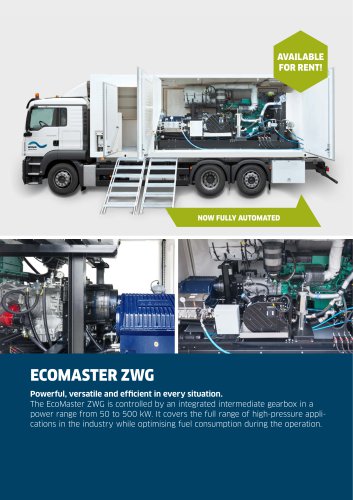

With operating pressures up to 1,500 bar and nominal flow rates up to 435 l/min, the Z-series is extremely flexible in a wide range of applications. In particular as the centrepiece of the WOMA EcoMaster ZWG with an integrated intermediate gear, these high-pressure pumps are the general purpose solution for almost every application. Good plunger guidance ensures a long service life for the sealing system. The pumps are fitted with plungers made of different materials depending on the requirements. Pumps with an operating pressure from 1,000 bar, for example, have robust carbide plungers for...

Open the catalog to page 9

Tank and vessel cleaning Tanks and containers must be periodically cleaned from the inside to remove all contaminants. The tank cleaning heads from the TankMaster series ensure optimum interior cleaning results at minimal cleaning times. Pipe cleaning Pipes are the veins of plants in all industrial areas and must therefore always be free from deposits. The cleaning of pipes with high-pressure water even enables getting into hard to reach places.

Open the catalog to page 11

Y-SERIES (1,000 BAR) Power packs for compact systems. The high-pressure pumps from the Y-series are exceedingly compact. Their small size and low weight make them especially suitable for use in compact high-pressure units.

Open the catalog to page 12

With operating pressures of up to 1,000 bar, the Y-series is outstandingly suited to many different cleaning tasks, e.g. in the chemical industry, oil and gas industry, as well as for marine applications. Depending on the fluid being used, the standard carbide plunger in the 70Y pump can be replaced by a fluid-resistant ceramic plunger. It is also possible to fit the pump with a suction valve lift for unpressurised circulation of the water within the pump head. The newly developed 30Y high-pressure pump extends the performance spectrum of the Y-series even further. With a required driving...

Open the catalog to page 13

2-SERIES (750 BAR) Power packs for harsh environments. The robust, yet inexpensive high-pressure pumps from the 2-series generate up to 750 bar. This makes them the preferred choice in particular for cleaning pipes, tube bundles and vessels.

Open the catalog to page 14

Regardless of how harsh the day-to-day working conditions may be, the pumps from the 2-series are ideally equipped to handle them, and in doing so offer outstanding value for money. They are particularly easy to maintain and offer a long service life. The 2-series pumps are build with ceramic plungers, which are extremely resistant to alkaline and acidic liquids. Specially coated steel plungers that are extremely hard- wearing and highly resistant to temperature shocks are available as an option. The plungers are additionally protected against contamination and damage by the newly...

Open the catalog to page 15

TECHNICAL DATA Performance data 702 Pinion shaft 750 1/min 1,000 1/min Gear ratio 1.00 1.00

Open the catalog to page 16

Tank and silo cleaning The internal cleaning is the central task of tank and silo maintenance. To keep production down times as little as possible, a quick and thorough cleaning is crucial. The dense spray pattern of the TankMaster cleaning heads guarantee optimum results in short times. Heat exchanger cleaning The processes in heat exchangers often lead to the formation of stubborn deposits, which, depending on the type, harden and reduce the flow or even completely block them. Regular and residue-free cleaning with high- ressure is p therefore essential for the necessary process...

Open the catalog to page 17All WOMA GmbH catalogs and technical brochures

-

WOMA EcoTherm Hot Water Unit

2 Pages

-

WOMA EcoMaster 700Z ZWG

2 Pages

-

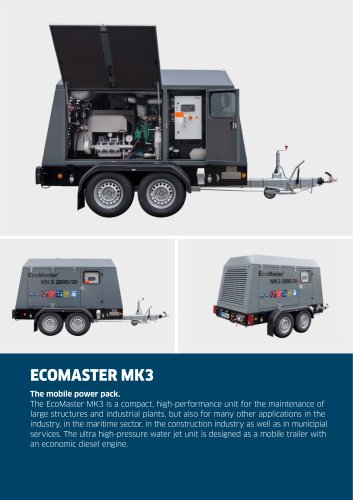

WOMA EcoMaster MK3

2 Pages

-

INDIVIDUAL SYSTEMS

2 Pages

-

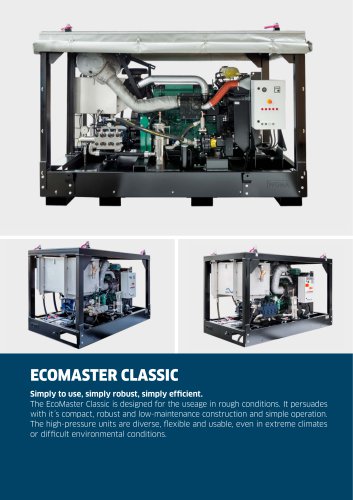

ECOMASTER CLASSIC

2 Pages

-

ECOMASTER ZWG

2 Pages

Archived catalogs

-

WOMA Waterjetting Tools

5 Pages

-

WOMA Ultra-High-Pressure Units

20 Pages