Catalog excerpts

MONITOR ANY AREA OF CONCERN ON YOUR CNC MACHINE TOOL OR FIXTURE SMART MANUFACTURING SOLUTIONS Sensor/Software Monitoring Suite DTect-IT combines high-precision sensor technology with advanced analysis capability to monitor, detect, and (depending on the application), correct anomalies occurring in the machining process. Using sensors for vibration, strain, high-resolution power, and/or analog (connecting any sensor with a 0 to ± 10 VDC signal), the user can monitor specific parameters to alarm and signal the CNC when irregularities are present. All data is recorded and accessible in the historical viewer to analyze and trend monitored data over time. PROMINENT APPLICATIONS Bar Feeder Vibration Detection Tool Wear and Breakage Detection Tool Clamping Integrity Surface Roughness Measurement Vibration Analysis Collet Clamping Force Detection Tapping Operations Probe Surface Scanning Spindle Bearing Analysis Signature Analysis Machine Health and Preventative Maintenance MONITORING AND ANALYSIS MODES FAULT DETECTION LIMIT ANALYSIS Limits can be learned automatically or set manually using the adjustable sliders DTect-IT recognizes when set upper and lower limits are exceeded, identifying an excessive condition (e.g. machine impact, overheating, extreme vibration) Work (area under the curve) limits can be enabled to calculate tool wear Indicates and time stamps machine faults and records data on either side of the fault for analysis Stop Monitor BEARING ANALYSIS DTect-IT measures spindle vibration to monitor bearing health for analysis Vibration signal is analyzed for the (1) Acceleration signature which tells the health of the bearings, (2) Velocity signature which detects misalignment, imbalance and looseness FREQUENCY ANALYSIS Set magnitude limits to monitor and detect anomalies within specific frequency bands Alarms and notifications are generated when magnitude limits (in decibels) are exceeded

Open the catalog to page 1

FEATURES Vibration Level History View Ideal for monitoring up to 4 tools Run multiple analyses simultaneously with a single sensor Application runs standalone or easily integrates with the CNC control Monitoring can be initialized from the user interface, CNC control, or digital input Collects raw data from any sensor (up to 62,500 data points/sec) Easily detects excessive bar feeder vibration (i.e. bent bar), and signals the CNC to Analyze historical monitoring data using the Analysis Viewer! automatically adjust spindle RPM, if needed SENSOR SPECIFICATIONS VIBRATION Vibration Sensor...

Open the catalog to page 2All Wolfram Manufacturing Technologies catalogs and technical brochures

-

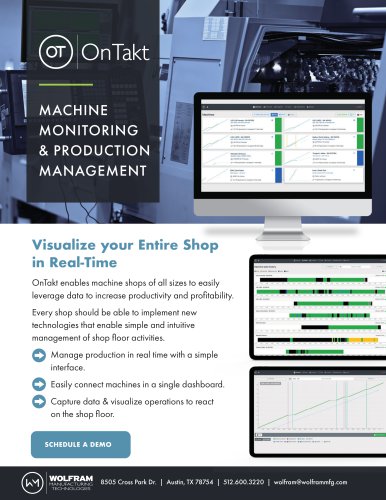

OnTakt

2 Pages

-

ToolConnect-Brochure

2 Pages

-

CEI-Smart-Light-Brochure

2 Pages