Catalog excerpts

A WIRTGEN GROUP COMPANY A WIRTGEN GROUP COMPANY A strong team for economical concrete paving Slipform Paver SP1500/SP1500 L

Open the catalog to page 1

TRACK UNITSBOTTOM-LAYER CONCRETE PAVER SP 1500PIVOTING LEGS Pivoting legs for full adjustment of the track units to the conditions prevailing on site. Hydraulically driven, separately height-adjustable and steerable track units for precise driving behaviour and high-precision concrete paving. As bottom-layer concrete paver in dual-layer concrete paving, the SP 1500 paves the bottom concrete layer. As top-layer concrete paver in dual-layer concrete paving, the SP 1500 paves the top concrete layer "wet-in-wet". Super smoother for a perfectly smooth surface finish. Eccentrically driven...

Open the catalog to page 2

Ergonomically designed, walkthrough operator’s platform for non-tiring, productive working. POWER UNIT High-powered, fuel-efficient diesel engine for concrete paving in the optimum performance and torque ranges. TELESCOPING MACHINE FRAME Machine frame telescoping in longitudinal direction to allow full adjustment to site conditions. 2 | 8 | CONVEYING SYSTEM Conveying system for transport of the top-layer concrete in front of the top-layer concrete paver. INSET PAVING MOULD Inset paving mould integrated into the machine frame and mounted between the track units. CONCRETE SPREADING Spreading...

Open the catalog to page 3

Outstanding features of the SP 1500 L slipform paver BOTTOM-LAYER CONCRETE PAVER SP 1500 L TRACK UNITS As bottom-layer concrete paver in dual- layer concrete paving, the SP 1500 L paves the bottom concrete layer. Hydraulically driven, height-adjustable track units for precise driving b ehaviour and high-precision concrete paving. TOP-LAYER CONCRETE P AVER SP 1500 L 1 | As top-layer concrete paver in d ual-layer concrete paving, the SP 1500 L paves the top concrete layer “wet-in-wet”. SUPER SMOOTHER Super smoother for a perfectly smooth surface finish. OSCILLATING BEAM Eccentrically...

Open the catalog to page 4

OPERATOR’S PLATFORM Ergonomically designed, walkthrough operator’s platform for non-tiring, productive working. POWER UNIT High-powered, fuel-efficient diesel engine for concrete paving in the optimum performance and torque ranges. CONVEYING SYSTEM Conveying system for transport of the top-layer concrete in front of the top-layer concrete paver. INSET PAVING MOULD Inset paving mould integrated into the machine frame and mounted between the track units. Automated insertion of dowel bars to maintain the surface levels of neighbouring concrete slabs. Electrically driven vibrators for reliable...

Open the catalog to page 5

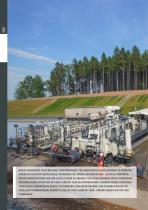

ROAD TRANSPORT IS INCREASING CONTINUOUSLY. TECHNOLOGICAL DEVELOPMENT IS FORGING AHEAD AT AN EVER FASTER PACE. OFFERING YOU MORE OPPORTUNITIES - ALSO IN CONCRETE ROAD CONSTRUCTION. WE ARE A KEY PLAYER IN DRIVING THIS DEVELOPMENT WITH PIONEERING TECHNOLOGIES. WITH THE SP 1500 L AND SP 1500 SLIPFORM PAVER. A MOBILE ROAD CONSTRUCTION PLANT. EXPERTISE IN HIGHLY AUTOMATED CONCRETE PAVING. FOR DURABLE ROADS OF EXCELLENT DIMENSIONAL STABILITY. THE SP 1500 L AND SP 1500 – PREDESTINED FOR TOP PERFORM

Open the catalog to page 6

Intelligence in concrete paving: this paving train is a high-speed train HIGH-QUALITY DUAL-LAYER CONCRETE PAVEMENTS WIRTGEN uses an efficient, tried-and-tested process for the production of dual-layer concrete pavements: the paving train consists of three separate units comprising the b ottom-layer paver, op-layer paver and TCM t texture curing machine. In the paving process, the SP 1500 / SP 1500 L slipform paver can be used as ottom-layer paver or top-layer paver b in accordance with customer specifications. The intelligent concrete paving process and resulting high daily...

Open the catalog to page 8

1 | Efficient: bottom- layer concrete and top-layer concrete are paved in immediate succession. 2 | The SP 1500 L and SP 1500 are used as either bottom-layer paver or top-layer paver in accordance with requirem

Open the catalog to page 9

Use as required: concrete paving with the SP 1500 or SP 1500 L CHOICE OF DIFFERENT COMBINATIONS: TWO OR FOUR TRACK UNITS Depending on requirements, customers can use the SP 1500 with four or the SP 1500 L with two track units as the bottom-layer or top-layer concrete paver. The two-tracked SP 1500 L slipform paver model offers the advantages of lower machine weight and shorter transport length. The our-tracked SP 1500, on the other hand, offers a significantly larger contact surface, thus effectively pref venting the machine from sinking in on soft ground. In addition, each of the...

Open the catalog to page 10

Top-layer concrete paver

Open the catalog to page 11

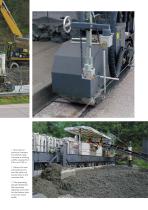

Save time and money starting with the bottom concrete layer A RELIABLE PAVING METHOD FOR SUPERIOR RESULTS Deposit the concrete for the bottom layer in front of the SP 1500 / SP 1500 L, and the machine will take care of the rest virtually automatically: a truck dumps the concrete in front of the ottom-layer paver, which spreads it b evenly across the entire width using a spreading plough. A eavy-duty mould paves the concrete in the h correct vertical and horizontal position while the paver keeps moving forward. Electrically driven vibrators then compact the concrete using igh-frequency...

Open the catalog to page 12

1 | Economical paving of inexpensive bottom-layer concrete at working widths ranging from 5.0 m to 15.25 m. 2 | Sensor for level and steering control; the track unit travels close to the concrete slab. 3 | The spreading plough distributes the previously deposited concrete for the bottom layer across the entire

Open the catalog to page 13

No need to interrupt production: automated insertion of dowel bars TOTAL AUTOMATION HELPS YOU EXPLOIT ALL OST-CUTTING POTENTIAL C The SP 1500 / SP 1500 L has yet another trump card to offer: automated insertion of dowel bars and tie bars into the concrete layer. The dowel bars are inserted parallel, the tie bars perpendicular to the concrete slab by means of vibration. Highlight of the process: the dowel bar inserter mounted on the machine can move in the direction of paving, meaning that it remains above the paving site without interrupting machine travel until the dowel bars have been...

Open the catalog to page 14All Wirtgen catalogs and technical brochures

-

COLD MILLING MACHINE W 210 F (i)

44 Pages

-

Cold Milling Machine W 200 Hi

52 Pages

-

COLD MILLING MACHINE W 200 F i

46 Pages

-

W 35 Ri COLD MILLING MACHINE

32 Pages

-

SP 64 / SP 64i

24 Pages

-

Slipform paver SP 1200

24 Pages

-

Side Feeder ISF 94 / ISF 94i

20 Pages

-

4200 SM

40 Pages

-

Cold Milling Machine W 210 XP

56 Pages

-

W 205 Cold Milling Machine

20 Pages

-

Foamed bitumen

28 Pages

-

S-Pack

8 Pages

-

Job reports and references

8 Pages

-

Surface Miner 2200 SM 3.8

36 Pages

-

Surface Miner 2200 SM

40 Pages

-

Cold milling

32 Pages

-

Cold Milling Machine W 1900

24 Pages

-

Side feeder ISF 850

8 Pages

-

Cold recycler 3800 CR

26 Pages

-

Slipform paver SP 1600

8 Pages

-

Surface Miner 2500 SM

22 Pages

-

Cold milling machine W 60i

20 Pages

-

Cold milling machine W 50 DC

32 Pages

-

Cold milling machine W 50

24 Pages

-

Cold milling machine W 35 DC

24 Pages

-

Dinting machine 2600

8 Pages

-

Slipform paver SP 150

20 Pages

-

Binding agent spreaders

20 Pages

-

Cold recycler 2200 CR

32 Pages

-

Recycler/Stabilizer WR 2000

28 Pages

Archived catalogs

-

Cold Milling Machine W35 Ri 2020

36 Pages