Catalog excerpts

DISA Trading (Shanghai) Co. Ltd. Room A901-903, Far East International Plaza No.319 Xian Xia Road Shanghai 200051 – PR China T: +86 21 6113 1799 F: +86 21 6113 1788 E: info.shanghai@wheelabratorgroup.com.cn Belgium Wheelabrator Group N.V. Airport Ring Center Maalbeekweg 61, B-1930 Zaventem T: +32 27190140 F: +32 27190145 E: info@wheelabratorgroup.be Canada Wheelabrator Group 1219 Corporate Drive Burlington, Ontario L7L 5V5 T: +1 (800) 845 8508 • T: +1 (905) 319 7930 F: +1 (905) 319 7561 E: info@wheelabratorgroup.com Czech Republic & Slovakia DISA Industries s.r.o. Za Balonkou 269 CZ-260 01 Príbram 1 T: +420 318 479 111 F: +420 318 479 333 E: pribram@wheelabratorgroup.com France Wheelabrator Group 28-30 Rue de Tournenfils, BP 19 91541 Mennecy-Cedex T: +33 (0) 1 64 57 21 21 F: +33 (0) 1 64 57 05 59 E: contact@wheelabratorgroup.fr Wheelabrator Group (Technology Centre) 24, rue Camille Didier BP 39 F-08001 Charleville-Mézières Cédex T: +33 (0) 324 33 63 21 F: +33 (0) 324 37 39 37 E: charleville@wheelabratorgroup.com Germany Wheelabrator Group GmbH Ferdinand-Porsche Str. 23 D- 51149 Köln T: +49(0) 2203 297 51 0 F: +49(0) 2203 297 51 60 E: info@wheelabratorgroup.de Wheelabrator Group GmbH (Technology Centre) Heinrich-Schlick-Strasse 2 D-48629 Metelen T: +49(0) 25 5688 0 F: +49(0) 25 5688 150 E: kontakt@wheelabratorgroup.de Hong Kong Wheelabrator Group Ltd. Unit 03, 11th Floor., Futura Plaza, 111-113 How Ming Street, Kwun Tong, Kowloon, Hong Kong SAR T: +852 2827 1927 F: +852 2877 6839 E: info@wheelabratorgroup.com.hk For more information please contact: Wheelabrator Group Ltd. 41 Craven Road, Altrincham, UK WA14 5HJ Norican Group is the parent company of DISA and Wheelabrator T: +44 (0)161 928 6388 F: +44 (0)161 929 0381 E: uk-info@wheelabratorgroup.co.uk www.wheelabratorgroup.com India DISA India Ltd. 5TH Floor, Kushal Garden Arcade 1A Peenya Industrial Area Peenya 2nd Phase, Bangalore 560058 T : +91 80 4020 1400 (01/02/03/04) F: +91 80 2839 1661 E: bangalore@disagroup.com Wheelabrator Group Ltd. 701 Blossoms, 36/100 Gidney Park, Salisbury Park, Pune 411037 - India T: +91 937 247 3560 F: +91 202 426 7623 E: info@wheelabratorgroup.com.hk Russia Wheelabrator Group Ul. Malakhitovaya 27, Building 1 129128 Moscow T: +7 495 1815548 F: +7 495 1815571 E: info@wheelabratorgroup.ru Spain Wheelabrator Group S.L.U. Gran Via de les Corts Catalanes, 133 - 8º B E-08014 Barcelona T: + 34 93 421 1266 F: + 34 93 422 3137 E: contact@wheelabratorgroup.es Japan DISA K.K. 4F, Sumitomo Shoji Nagoya Marunouchi Bld., 3-5-10 Marunouchi Naka-ku Nagoya 460-0002 Japan T: +81 52 950 7260 F: +81 52 971 9450 Switzerland DISA Industrie AG Kasernenstrasse 1 CH-8184 Bachenbülach Switzerland T: +41 44 815 40 00 F: +41 44 815 40 01 E: zurich@wheelabratorgroup.com Mexico WG Plus Mexico S. De R.L. de C.V. Av. Universidad 1290, Local #19, Colonia Casa Bella San Nicolas de los Garza, Mexico 66428 T: +52 81 8302 3631 F: +52 81 8302 3632 E: mexico@wheelabratorgroup.com United Kingdom Wheelabrator Group Ltd. 41 Craven Road Altrincham, UK WA14 5HJ T: +44 (0) 161 928 6388 F: +44 (0) 161 929 0381 E: uk-info@wheelabratorgroup.co.uk Poland Wheelabrator Group ul. Wiertnicza 115 PL-02-952 Warszawa T: +48 (0) 22 6 51 70 91 F: +48 (0) 22 6 51 70 92 E: info@wheelabratorgroup.pl USA Wheelabrator Group 1606 Executive Drive LaGrange, GA 30240 T: +1 (800) 544 4144 • T: +1 (706) 884 6884 F: +1 (706) 884 0568 E: info@wheelabratorgroup.com Subject to technical alteration • 10/09 • © wheelabrator China Wheelabrator Group Ltd. Room 1823, Block 2, Bright China Chang An Building, No.7 Jianguomen Nei Avenue, Dongcheng District, Beijing 100005 - PR China T: +86 10 5911 1811 - 12/13 F: +86 10 5911 1810 E: info.beijing@wheelabratorgroup.com.cn Surface preparation

Open the catalog to page 1

Shipyard Solutions Wheelabrator offers the widest range of surface preparation and engineering solutions.The sheer size of components and steel plates found in the shipping industry demands quite specic engineering capability. Wheelabrator‘s expertise has been tried and tested over many years, and many manufacturers have come to depend on the know-how, reliability and high quality service provided by Wheelabrator Group. This brochure is intended to give a brief overview of the many technologies and applications available. 2 3

Open the catalog to page 2

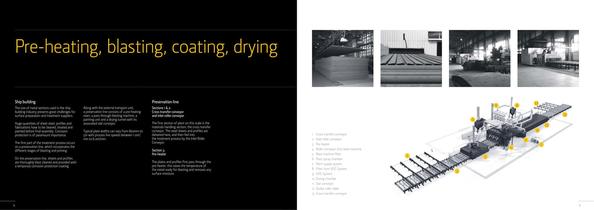

Pre-heating, blasting, coating, drying Ship building The size of metal sections used in the ship building industry presents great challenges for surface preparation and treatment suppliers. Huge quantities of sheet steel, profiles and fabrications have to be cleaned, treated and painted before final assembly. Corrosion protection is of paramount importance. The first part of the treatment process occurs on a preservation line, which incorporates the different stages of blasting and priming. On the preservation line, sheets and profiles are thoroughly blast cleaned and provided with a...

Open the catalog to page 3

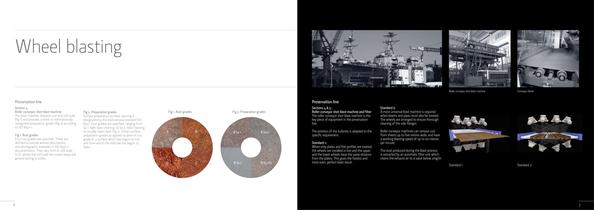

Wheel blasting Roller conveyor shot blast machine Preservation line Section 4: Roller conveyor shot blast machine The blast chamber removes rust and mill scale (fig 1) and provides a finish to internationally recognised preparation grades (fig 2) according to ISO 8501-1. Fig 1. Rust grades Four rust grades are specified. These are defined by precise written descriptions and photographic examples in ISO 8501-1 documentation. They vary from A: mill scale, to D: where the mill scale has rusted away and general pitting is visible. Standard 1 Standard 2 Preservation line Fig 2. Preparation...

Open the catalog to page 4

Quality control Quality control Quality control The controlled removal of rust and scale, and the generation of a consistent surface profile are critical to the successful bonding of coatings that follow. Throughout these processes the strict application of exhaustive quality controls is mandatory. Priming Sections 6-9: Paint spray chamber, voc-system and filter The various plate and profile widths are automatically identified and are coated in a continuous process with a weld-primer coating thickness of approximately 15 - 25μm. Paint dust and solvents (if no water based paint is used) are...

Open the catalog to page 5All Wheelabrator catalogs and technical brochures

-

MB Tumblast Machines

4 Pages

-

Compact Blast Machines

1 Pages

-

CFX 200 Peening cell

1 Pages

-

CFX 200 LC Peening cell

1 Pages

-

CFX 400 LC Peening cell

1 Pages

-

CFX 600 Peening cell

1 Pages

-

MP 600 Peening system

1 Pages

Archived catalogs

-

Steel construction

6 Pages

-

Aerospace NEWS

12 Pages

-

TITAN turbine

2 Pages