Catalog excerpts

PMA KS 800 8-channel controller in housing for rail mounting CAN/ CANopen, PROFIBUS-DP, DeviceNet, RS 485/422 Connection of Engineering Tool or local operation Self-Tuning to the setpoint without oscillation Automatic start-up circuit Switch-over to output “hold ”on sensor break Monitoring for heating current and actuator 3 configurable alarm outputs or relays 8 analog outputs (option) Direct connection of melt pressure sensors (option) GENERAL The microprocessor-controlled KS 800 ensures precise, low-cost multi-loop control of temperature, and features an interface for bus or field-bus. Standard functions such as “set-point lowering” and “heating/cooling with four alarms” make the KS 800 ideally suited for temperature control of plastics processing machines, heated moulds, packaging machines, tempering units, and other similar thermal processes. Furthermore, with high-power heating elements (e.g. in hot-runner moulds), the selectable functions “output hold ”in case of sensor break, and “start-up circuit ”ensure increased element life and prevent interruptions during Production. The self-tuning feature guarantees very short start-up times. For implementing continuous and split-range controllers, the KS 800 can be fitted with 8 additional analog control outputs. DESCRIPTION The following description is based on the fact that every one of the 8 control loops contains a completely independent controller. Input circuit monitoring Incase of a fault in sensor or leads, the built-in monitor provides increased operational safety. The controller output ac- tion after monitor triggering can be configured for: Ø downscale (min. output) Ø upscale (max. output) Ø outputs switched off Ø switch-over to average output value Thermocouple input The monitor is triggered by wrong sensor polarity or TC break. Resistive input The input is monitored for a break or a short circuit in the sensor and leads. Measurement value correction for thermocouples, Pt 100, linear input The correcting function is used to change or scale he measurement value. It can be applied either for zero offset (b)or for gain adjustment (m), or both, according o he equation “mx +b ”. For this, the controller computes the values for m and b from two input values (x1in, x2in)and two set-points (x1out, x2out). Easy calibration is possible online via an operating page of the engineering tool. Heating current monitoring and alarm The KS 800 has an input for an external current transformer, whereby rectification of the input signal is done on board. All the connected heating leads of the KS 800 ’s controllers are passed through the current transformer. If the monitoring function has been activated, the heating outputs of all the con- advanced line Multiple temperature controller trol loops are switched on briefly in succession, and the heating current is measured. If the measured current is lower than a defined limit value, this information can be signalled to one of the alarm outputs or transmitted via the field bus. Similarly, the heating output can be monitored for a short-circuited actuator (SSR).In this case, the heating current is measured when the heating output is switched off. If the measured current exceeds 3% of the selected range, an alarm is triggered. In addition to checking for exceeded heating current limits, the actuator (solid state relays) is checked for short circuit. With the outputs switched off, the heating current must not exceed 1,5% of the selected heating current measuring range. With detected errors, the relevant channel number is also output by KS 800. Leakage current monitoring Heating elements with a high leakage current (e.g. due to penetrated moisture) are detected by this circuit. Monitoring is carried out with the heating output switched off. An external current relay monitors the difference between the phase currents and the current in the neutral lead. If the difference exceeds a pre-defined value of 10...100 mA, the system transmits a 24 V DC alarm signal to the controller module. Through cyclical activation of the heating circuits and corresponding scanning, a single current relay can be used for all 8

Open the catalog to page 1

control loops. The leakage current moni- tor is coupled internally to the heating current monitor. Controller and positioner functions as a two-point or three-point controller, three-point controller with water evapo- ration cooling, as a master controller or as a three-point stepping controller. Al- ternatively, two and three-point control- lers can be configured for continuous or split-range control. All versions feature auto/manual switch-over, also via the in- In manual operation, the output has an adjustable duty cycle of 0...100%. With cascaded operation, the slave controllers can...

Open the catalog to page 2

of the heating elements, the duty cycle is reduced to 14 during start-up. The start-up set-point (e.g.95°C)is main- tained during the selected start-up hold- ng time. Subsequently, the controller uses main set-point W. "Hold "function for output signal In order to continue with production in case of sensor break, the KS800 offers the possibility of maintaining the temper- ature a the last mean value of the output On sensor break, the KS 800 generates an according signal via the alarm outputs or via the field-bus, so that the sensor As soon as the KS 800 detects a valid in- put value after...

Open the catalog to page 3

Direct voltage nput span scalable via measurement Scanning frequency With thermocouple or Pt 100 input, all 8 nputs are scanned within 625 ms. Heating current input Connection of normal current transform- e.g. for PMA standard current trans- Digital inputs The 4 digital inputs can also be config- ured as digital outputs. Galvanic isolation Current sink (IEC 1131 type 1) The digital inputs are galvanically isolated from the other temperature inputs. Digital inputs for relay switching Current sink (IEC 1131 type 1) galvanically isolated Stand-alone temperature controller Stand-alone...

Open the catalog to page 4All West Control Solutions catalogs and technical brochures

-

Rail Line Brochure

6 Pages

-

Product Catalogue

52 Pages

-

KS98-2 Brochure

6 Pages

-

Dual Loop Temperature Controller

15 Pages

-

CAL Thermostats Brochure

4 Pages

-

CAL Controller Brochure

4 Pages

-

Company Profile

16 Pages

-

3-phase with heatsink

8 Pages

-

2-phase with heatsink

8 Pages

-

3-phase without heatsink

4 Pages

-

2-phase without heatsink

4 Pages

Archived catalogs

-

Special-RTD-Pt100

2 Pages

-

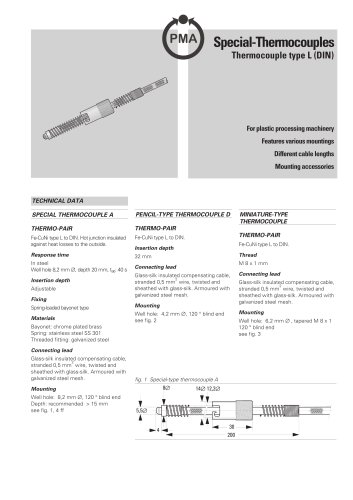

Special Thermocouple

2 Pages

-

Thermocouples

4 Pages