Catalog excerpts

3.Standard automatic operation bow can realize the automatic con-trol of temperature, liquid medicine pH (optional), bow speed (optional) etc. key technological parameters, so as to guarantee the stability and reliability of continuous counter-current extracting technology. 4.Near-infrared online detection system can be allocated for the realtime measurement of content of effective components of tradition-al Chinese medicine for the convenience of optimizing the technological parameters. 5.Advanced traditional Chinese medicine manufacturing process analysis software platform and database management system can be allocated. Application Examples Tank unit type counter-current extracting technology for soluble salvianolic acids Comparison project Tank group counter current extraction Danshensu extract content (mg/g) Amount of solvent used per gram of medicinal material (ml) Compared with the hot reflux extraction process, the extraction rate is increased by 19.4% and the solvent usage is reduced by 3/4. Tank unit type counter-current extracting technology for total panax notoginseng saponins Tank group counter current extraction room temperature Ethanol concentration (%) Number of extraction tanks Comparison project Soxhlet Ultrasonic extraction extraction Concentrator Pharmacy Extraction time per gram of medicine (min) Amount of solvent used per gram of medicinal material (ml)

Open the catalog to page 1

New Energy Saving And Environmental Protection Concentrator Main efficacy description The products are mainly adapted to the concentrated production process of traditional Chinese medicine, health care products, natural seasonings, food additives, food, chemical and other industries. It can provide different proportions of extracts for different drying production methods. It has wide application range, and has advantages of easy operation and low maintenance rate. SJN series concentrator is a new generation of high-efficiency and energy-saving multifunctional concentrator successfully, redesigned...

Open the catalog to page 2

Technical Parameter Relative density Outline dimension (Length * width * height) ( m ) Recycling water consumption ( L/h ) Evaporation temperature℃ Steam pressure (Mpa) Container class First type (Single-effect heater) 1.The diversion trench circulative evaporation technology is adopted: Compared with traditional structure, the evaporation efficiency is increased by about 15%. Meanwhile, it can effectively prevent bubbles from being produced during material evaporation and can avoid foam entrainment. 2.The flat bottom evaporation technology is adopted: Compared with traditional conical bottom...

Open the catalog to page 3

Product features and description The company has extensively combined the advantages of concentrating equipment and other industry concentrating equipment, and combined with the characteristics of traditional Chinese medicine extracts, designed and developed a series of LJN three-effect (double-effect, single-effect) falling film continuous feed concentrator. The features of the device are as follows: 1.Continuous feeding and discharging, the system is stable and easy to operate. When working in this series of equipment, it only needs to adjust various parameters as required at the initial...

Open the catalog to page 4

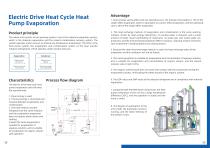

Electric Drive Heat Cycle Heat Pump Evaporation Product principle 2. The heat exchange medium of evaporation and condensation is the same working medium, driven by clean energy (electricity), no cooling water is required, and a small amount of boiler steam (preheating of materials), no waste gas and waste water are produced, and the environmental protection effect is obvious, reducing Carbon emissions save investment in building boilers and cooling towers. The whole unit consists of two working systems: one is the material evaporation system, which is the material evaporation and the solvent...

Open the catalog to page 5

QN Circular Concentration Can Product features and description Protection Concentrator Engineering Case The spherical concentrating tank is mainly composed of four parts: a concentrated main body, a condenser, a vapor-liquid separator and a liquid receiving tank. It can be used in the processes of concentration, distillation and recovery of organic solvent in the pharmaceutical, food, chemical and other industries. Due to the concentration under reduced pressure, the concentration time is short and the effective components of the heat sensitive material are not destroyed. The contact between...

Open the catalog to page 6All Wenzhou Jinbang Light Ind Machinery Co. catalogs and technical brochures

-

Molecular Distillation

2 Pages

-

Vacuum Belt Dryer

7 Pages

-

Separation

2 Pages

-

Falling Film Evaporator

1 Pages

-

Extraction

3 Pages

-

Distillation Column

2 Pages

-

Containers

4 Pages

-

Case

6 Pages

-

Jinbang catalog

47 Pages