Catalog excerpts

EASY from here on www.weller-tools.com The right iron for my application. www.weller.de/toolselector The right technology for my application. www.weller.de/applicationfinder Weller Tools GmbH Carl-Benz-Strasse 2 74354 Besigheim Germany Phone: +49 7143 580-0 E-mail: info@weller-tools.com

Open the catalog to page 2

Soldering technology Professional Filtration Filtration Dispensers Professional Electric Screwdriver Professional Precision Tools Side cutters and tip cutters, pliers, tweezers, special Erem tools, toolkits

Open the catalog to page 3

Soldering technology Solid Stations Low Voltage Soldering Iron Performance Line Magnastat Soldering Irons Technology Line Line Voltage Soldering Iron Heating Elements for Solder Robots96 Inert Gas Soldering Iron Soldering Irons Desoldering Irons Soldering iron and safety rest Performance Line Soldering tips and nozzles Soldering Tips Technology Line Desoldering Nozzle series Soldering Iron Desoldering Iron Preheating plates Soldering bathes Circuit board holder Temperature Measuring Filtration Volume fume extraction Exhaust hood Easy-Click 60 extraction arms Tip extraction Tip extraction...

Open the catalog to page 4

Electric Screwdriver Electronic screwdriver Precision Tools Side cutters and tip cutters Precision tweezers Locking gripping tweezers Wafer tweezers Tungsten-carbide cutters Cutting tweezers Special applications Stripping tweezers Extraction tweezers Pneumatic side and tip cutters 285 Distance cutters Stripping pliers Forming pliers Special tools IC and SMD tools High-precision tools for optical fibers325 Vacuum micromanipulator Tools Knives and blades Shear cutters and pliers Screwdriver and nutdriver sets Service kits and sets Tool cases

Open the catalog to page 5

INNOVATION, GLOBALIZATION, COLLABORATION 1941 WELLER SOLDERING GUN Carl E. Weller takes out the first patent. Carl E. Weller Founder facility opens in Besigheim, ermany G Weller manufacturing begins in aston, PA, USA E The patented Magnastatcontrolled soldering pencils and soldering stations are the core business.

Open the catalog to page 6

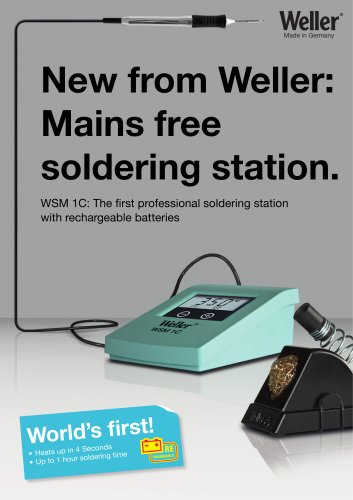

A name known round the world! For decades, the Weller name has stood for pioneering soldering solutions. Weller is the global leader in manual soldering technology and offers a complete, user-oriented customer and distribution service, with their own sites in over 30 countries. Innovation By answering our users’ demand for faster, flexible and more functional products, Weller continues to be the market leader in developing innovative, economical soldering solutions. Weller Tools is responding to the signs of the times and presenting the new temperature-controlled soldering station with...

Open the catalog to page 7

The complete solution for your WORKBENCH By expanding its product portfolio, Weller Tools is setting new benchmarks while laying the foundation for complete expert workbench solutions from a single source. Components in areas including classic soldering applications, extraction and filter systems, tweezers and pliers, screw and robot solutions as well as BGA/QFP and repair applications ensure a coordinated and highly productive electric desktop and installation solution. FIRST CHOICE FOR CUSTOMERS Weller continues to transform the results of successful collaboration with our customers and...

Open the catalog to page 8

Everything from a single source from Weller Like Swiss clockwork Erem tools feature craftsmanship of the best quality. Produced in Switzerland, Erem tools are the result of more than 40 years of consistent product development and expertise. Making the job easier With Weller Performance Line, only a single control unit is still required, which works as a benchtop controller. Traceability keeps your quality at the highest level. Potential equalization The soldering stations from Weller all have a unique option for potential equalization.

Open the catalog to page 9

PERFORMANCE LINE performance HIGH PERFORMANCE AT ITS BEST COMPLETE COMPATIBILITY HIGHEST PERFORMANCE Use as benchtop controller Integrated USB ports provide WX stations with a connection to and control over soldering fume extractors, preheat plates and programmable logic controllers (PLC). The connected tools feed back their parameters and status to the display. FIVE PROS – ANY CHALLENGE Safe manual soldering Weller WX stations make the manual soldering process safer, a crucial factor in the automotive, aerospace and medical technology industries. This is guaranteed by temperature and tool...

Open the catalog to page 10

TECHNOLOGY LINE technology THE CAN-DO SOLDERING STATIONS. Quick change system Unique LC display with a detailed overview of all functions. Adjustable background illumination. Power bar graph allows visual monitoring of the easily-readable output power from the station to the soldering iron tip. Passive tip system allows quick exchange of heating elements when the iron is hot. Can easily switch out tips. Tip replacement independent of the heating element. Stackable units The WT 1 / WT 1H soldering stations can be stacked on the WTHA 1 hot air station, or on each other, saving space on the...

Open the catalog to page 11

BENCHTOP Controller Integrated USB ports provide WX stations with a connection to and control over soldering fume extractors, pre-heat plates and programmable logic controllers (PLC). The connected tools feed back their parameters and status to the display. USB port Firmware updates and registration are quick and easy using USB sticks. Multifunctional tool detection Robot output All connected tools and accessories are detected automatically by the stations and their name(s) shown. A digital, optically decoupled robot connection comes standard. HIGHEST PERFORMANCE ONLY ONE CENTRAL CONTROL...

Open the catalog to page 12

TRACEability Traceable Process Control. WELL ER IS TRAC EAB IL IT Y QUAL IFIED The following workflow diagram depicts a serial number with bar code integrated PCB production using the Weller WX station. The workflow includes interaction by the operator and the dialog of the Traceability System with the WX-station. Control System TRACEABILITY WORKFLOW WELLER EQUIPMENT Begin processing of product: Scan PCB or product to be soldered. 4.b. Visual process control via Weller LED ring light on the iron. 2. Transmission of data to the Traceability System. 3.a. Prepare WX station: The...

Open the catalog to page 13All Weller catalogs and technical brochures

-

RTU

2 Pages

-

Weller FT Cataloge

52 Pages

-

WellerFT Laserline

4 Pages

-

FlowinSmart Brochure

2 Pages

-

Erem Image Brochure

8 Pages

-

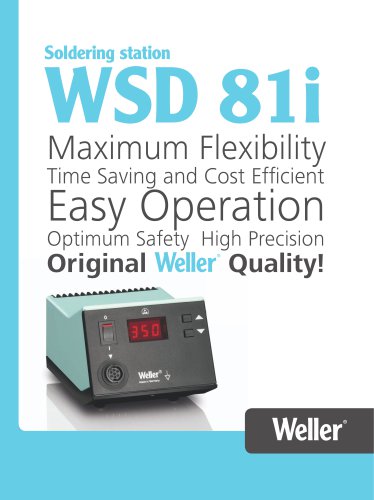

WSD 81i Brochure

12 Pages

-

Generation WT Brochure

13 Pages

-

WTQB 1000 Rework System

5 Pages

-

KDS834A

1 Pages

-

KDS141P

1 Pages

-

KDS14TNP

1 Pages

-

Fume Extraction Solutions

28 Pages

-

WR3M ? High - End Rework

28 Pages

-

wide band gas filter

2 Pages

-

WX2

2 Pages

-

WXD2

8 Pages

-

WAH35

1 Pages

-

Barrel for WSP 80

1 Pages

-

LT1

1 Pages

-

KDS824A

1 Pages

-

KDS301

1 Pages

-

KDS806V

1 Pages