Catalog excerpts

engineering adhesives Deadlocking permanent 83-21 BLOCCANTE RAP IDO ALTA RESISTENZA RETAINER EAST SETTING HIGH STRENGTH esivo Istantaneo hesif Instantane tant Adhesive kundenkleber condelijm abblim irtiglim Technical Information www.loxeal.com

Open the catalog to page 1

Made in Loxeal Loxeal® Engineering Adhesives is an Italian Company supplying a full range of high quality Adhesives and Sealants and providing industrial solutions for over 30 years. The Company Quality System was certified in 1993 and has been improved since then, granting the high quality level of our products. Our Anaerobic, Epoxy, Structural Acrylic, UV-light curing, Polyurethane Adhesives and other Complementary Products have been acknowledged to perform at the highest requirements. Many products have been tested by international Laboratories and certified according to regulations in...

Open the catalog to page 2

“Made in Loxeal” ensures a high quality for all our products, which is based on research, professionality and expertise. The best warranty of the quality of our products comes from all the international certifications and approvals that we achieved through the years in many different fields. Wide range of high quality products Development of customized formulations In-house prototype testing Sales and technical support to provide an ongoing application assistance Complete in-house manufacturing cycl

Open the catalog to page 3

CONTENTS Anaerobic Adhesives pag. 1 Liquid resins designed to cure when air is absent and metal surfaces are present. The adhesive fills all imperfections and gaps, providing better stress distribution on the full joint surface. The cured adhesive provides an excellent sealing against water, gas, oils, industrial fluid and chemicals. Fixture time depends on: gaps between surfaces, kind of metals, surface treatment and temperature. Operating temperature: -55°C/+150°C, up to +250°C for special grades. To replace traditional thread sealing materials such as hemp, PTFE tape, etc. Approved...

Open the catalog to page 4

Threadsealing Anaerobic threadsealing adhesives seal and lock threaded connections against pressure of gas, air, water, oils, hydrocarbons and many chemicals. They replace hemp and PTFE tapes and are available in various grades of locking strength with resistance to various chemicals. Certified according to various international standards, e.g. DVGW, NSF, WRAS, KTW, BAM, WATER MARK. LOCKING TORQUE BOLT M10 X 20 ZINC - QUALITY 8.8 NUT = 0,8 d STANDARD ISO 10964 CLASS OF LOCKING BROOKFIELD VISCOSITY 1 = LOW STRENGTH - EASY TO DISMANTLE HT = HIGH THIXOTROPY 2 = MEDIUM STRENGTH - POSSIBLE...

Open the catalog to page 5

Threadlocking Anaerobic threadlockers lock studs, nuts, screws and any threaded fasteners. The adhesive prevents loosening caused by vibration, mechanical and thermal shock. Threadlocking adhesive also inhibits fretting corrosion and prevents the seizure and galling. LOCKING TORQUE BOLT M10 X 20 ZINC - QUALITY 8.8 NUT = 0,8 d STANDARD ISO 10964 CLASS OF LOCKING BROOKFIELD VISCOSITY 1 = LOW STRENGTH - EASY TO DISMANTLE HT = HIGH THIXOTROPY 2 = MEDIUM STRENGTH - POSSIBLE TO DISMANTLE MT = MEDIUM THIXOTROPY 3 = HIGH STRENGTH - PERMANENT LOCKING LT = LOW THIXOTROPY F = Fluorescent:...

Open the catalog to page 6

Liquid Gasketing Gasketing anaerobic adhesive seals flat mating surfaces and joins flanges on pumps, gearboxes and differential housings. It replaces preformed gaskets and allows contact between metal parts forming a seal which is not prone to creep or relaxation. It forms a flexible and / or elastic gasket resistant to vibration, heat, oil and other industrial fluids. Parts can be disassembled using normal tools. LOCKING TORQUE BOLT M10 X 20 ZINC - QUALITY 8.8 NUT = 0,8 d STANDARD ISO 10964 CLASS OF LOCKING BROOKFIELD VISCOSITY 1 = LOW STRENGTH - EASY TO DISMANTLE HT = HIGH...

Open the catalog to page 7

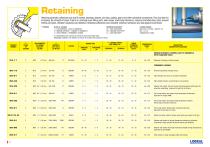

Retaining Retaining anaerobic adhesives lock and fit bushes, bearings, sleeves, pin hubs, pulleys, gears and other cylindrical components. They are ideal for increasing the strength of press fit parts or retaining loose fitting parts, allow larger machining tolerances, reducing manufacturing costs, prevent fretting corrosion, vibration loosening and distortion. Retaining adhesives have excellent chemical resistance and seal against most fluids. '*REMARK CLASS OF LOCKING 1 = LOW STRENGTH - EASY TO DISMANTLE 2 = MEDIUM STRENGTH - POSSIBLE TO DISMANTLE 3 = HIGH STRENGTH - PERMANENT LOCKING...

Open the catalog to page 8

Instant Adhesives Cyanacrylate adhesives are for instant and structural bonding of rubber, metals, ceramic, leather and a variety of plastics. Best results can be obtained with joint gaps of less than 0.1mm up to 0.2mm for special grades. The service temperature range is between -50°C and +80°C, although new high-temperature resistant formulations are available for use up to 180°C. For porous surfaces or for vertical application a gel grade is available. (1) ISO 4587 Standard (2) ISO 10123 Standard (*) Relative setting time (5= max, 1 = min.)

Open the catalog to page 9

Activators & Surface Conditioners for Anaerobic Adhesives, Acrylic Adhesives, Cyanoacrylate Adhesives The activators are specially designed products to speed up the cure of Anaerobic Adhesives. Typical conditions of use are low temperatures, large gaps, inactive or passive surfaces. CLEANER 10 Fast drying cleaner and degreaser to optimally prepare the surfaces to be bonded. Suitable for metal, ceramics, rubbers and plastics. Available in aerosol form. CR 1 CA remover solvent based. To remove and clean from cured CA adhesive and to debond parts cured with CA adhesives. CR 5 Low odor, low...

Open the catalog to page 10

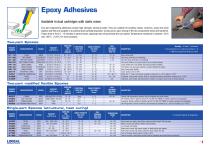

Epoxy Adhesives Available in dual cartridges with static mixer. Two-part engineering adhesives provide high strength, structural joints. They are suitable for bonding metals, ceramics, wood and some plastics and they are supplied in a practical dual cartridge dispenser. Curing occurs upon mixing of the two components (resin and hardener). Fixture time is from 5 - 10 minutes to several hours. Applying heat will accelerate the cure speed. Temperature resistance is between -30°C and +80°C, +120°C for some products. Two-part Epoxies

Open the catalog to page 11All Wekem catalogs and technical brochures

-

Wekem Catalog 2016

70 Pages