Catalog excerpts

Technical Information Mirror bonding COSMO® HD-100.400, COSMO® HD-100.450 & COSMO® HD-100.800 Bonding of mirrors on glass surfaces coated as per DIN EN 1306 need adhesive systems that meet the requirements made in the Technische Richtlinie des Glaserhandwerks Nr.11 (Technical regulation of the glazing trade), current edition. Always the aging-resistant, compatible bonding of the rear side of the mirror is in the focus. If unsuitable systems are used or the mirror bonding method is bad, this can cause problems like ▪ Shining through of the adhesive bead ▪ Tarnishing of the mirror ▪ Peeling off of the coating from the glass ▪ Adhesion loss up to the complete peeling off of the adhesive from the mirror surface ▪ Boundary changing effects . Observing the generally applicable instructions for use and the use of the products ▪ COSMO® HD-100.400 (1-C-MS-adhesive) ▪ COSMO® HD-100.450 (1-C-MS-assembly adhesive) ▪ COSMO® HD-100.800 (1-C-MS-assembly adhesive) ▪ COSMO® CL-300.150 (cleaning agent) we could obtain the best results in our tests referring the aging-resistant bonding of rear sides of mirrors. Also after intensive weathering and aging tests, no adverse effects could be determined. Instructions for use Preparation of the glued surface on the rear side of the mirror: The lacquer coat on the rear side may not be damaged. Mechanical influences, e.g. sanding of the lacquer coat, or scratches caused by sharp objects are to be avoided. Residue, dust and oily pollutions are removed using the cleaning agent COSMO® CL-300.150. Preparation of glued surface - substrate: The different substrates must be clean, stable and free from oil, grease and ingredients with strong migration ability, like softeners. Preparation of materials: The glued mirrors or the substrate should be climatically adapted to the room climate to avoid tension in the later joint. Geometry of adhesive joints In living rooms, or for mirror surfaces whose height is shorter than 1 m: Generally, a minimum distance between the mirror and the substrate of 5 mm must be kept to provide for sufficient rear ventilation. In wet rooms, or for mirror surfaces higher than 1 m: The minimum distance between mirror and substrate is here at least 10 mm. Furniture production: Depending on the design, the mirror should have a minimum distance to the furniture surface of at least 0.2 mm. Length of bonded joints: The length of the applied beads shall not exceed 200 mm. The distances between the beads of approx. 200 mm are to be kept. Alignment of bonded joints: The adhesive beads or the fixation aids are always to be applied VERTICALLY! Weiss Chemie + Technik GmbH & Co. KG Hansastraße 2 D-35708 Haiger

Open the catalog to page 1

Technical Information Mirror bonding COSMO® HD-100.400, COSMO® HD-100.450 & COSMO® HD-100.800 No oversized and/or horizontal beads, no adhesive bead in X-arrangement as well Per 1 kg of mirror weight, an adhesive surface of 10 cm3 with adhesive applied as a bead is preferred. Ambient temperature: Please find the application temperature of the adhesive in the corresponding Technical Data Sheet. Application temperatures higher than +15 °C are ideal. Too high application temperatures or above +27 °C essentially reduce the pot life of the adhesive and adhesion problems (missing coating effect)...

Open the catalog to page 2All Weiss Chemie catalogs and technical brochures

-

COSMO®CL-300.140 SPECIAL

1 Pages

-

COSMO®HD-200.121

4 Pages

-

COSMO®HD-100.800

3 Pages

-

COSMO®HD-100.500

3 Pages

-

COSMO®HD-100.480

3 Pages

-

COSMO Adhesives

9 Pages

-

COSMOPU-190.110

3 Pages

-

COSMOPU-180.150

3 Pages

-

COSMOPU-100.200

3 Pages

-

COSMOPU-100.250

3 Pages

-

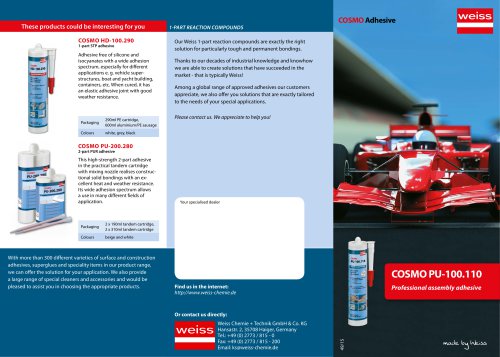

COSMOPU-100.110

3 Pages

-

COSMO PU-100.110

2 Pages

-

Cyanoacrylate Instant Glues

2 Pages

-

Airtight Bonding

20 Pages

-

COSMO ENERGY

2 Pages

-

COSMO Composite panels

2 Pages

-

Focus on Weiss

17 Pages

-

facade_elements

8 Pages

-

film lamination technology

2 Pages

-

COSMO Sandwich elements

2 Pages

-

beidseitig ALU, XPS-Kern

1 Pages

-

COSMO SL-660.110

3 Pages

-

COSMO CA-500.200

3 Pages

-

COSMO CA-500.170

3 Pages

-

COSMO CA-500.140

3 Pages

-

COSMO-ENERGY

2 Pages

-

Composite panels

2 Pages

-

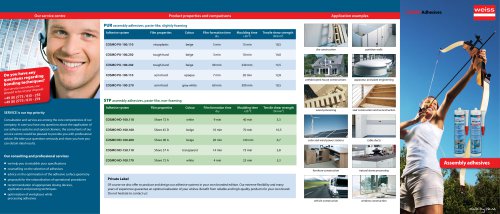

Assembly adhesives

2 Pages

-

COSMO FOAM - Composite panel

2 Pages

-

COSMO PU-100.200

2 Pages

-

PUR adhesives (1-part)

2 Pages

-

Adhesives for airproof bonding

16 Pages

-

CA adhesives

2 Pages

-

Facade elements

8 Pages

-

COSMO CA-500.120

3 Pages

-

COSMO CA-500.110

3 Pages

-

Composite panel

2 Pages

-

COSMOPLAN S

2 Pages

-

Window - Door - Façade

2 Pages

-

Cleaning & Care Service Sets

2 Pages

Archived catalogs

-

COSMO Sandwich elements 2018

2 Pages