Catalog excerpts

Technical Data Sheet Special Properties ▪ Aluminium window and door manufacturing for bonding of corner connectors ▪ semi-hard adhesive joint ▪ Window and door construction ▪ Board joint bonding of cassettes in the wood, window and front door area ▪ Thixotropic, does not drop off ▪ Stair construction and building trade ▪ With many assembly bonding processes ▪ Thin layers are transparent ▪ Compatible with natural stone ▪ Expands (foams) during the curing process! ▪ Joint filling ▪ Diverse industrial fields ▪ Good adhesion characteristics to several types of wood, and building material, ceramics, metal, duroplast and thermoplastic after appropriate preparation of the surface. ▪ Meets the requirements as per DIN EN 14257 (WATT 91) ▪ Good bonding strength ▪ Good bonding strength at heat ▪ Can subsequently be powder-coated (30 min/+200 °C) Certificates / Test reports ift Rosenheim If wood is glued to wood, it achieves the durability class D4 as per DIN EN 204. Test report No.: 505 25079/2 Technical Data Basis Colour hard-dry Skinning time - dry at +20 °C, 50 % r. H., applied quantity 500 μm-PE/PVC Skinning time - wet at +20 °C, sprayed with water; applied quantity 500 μm-PE/ PVC Curing time at +20 °C, 50 % r. H. until ~75 % Curing time at +20 °C, 50 % r. H. until it reaches the final strength Functional strength depending on application at +20 °C Applied quantity depending on carrier material Processing temperatures adhesive and substrates General Information Paint the bonded workpieces only after the adhesive has cured completely; if they are painted too early, formation of paint bubbles cannot be excluded. If permanent humidity impact is expected, the bonded joints/bonded surfaces must additionally be sealed/protected using a "suitable sealant". Weiss Chemie + Technik GmbH & Co. KG Hansastraße 2 D-35708 Haiger

Open the catalog to page 1

Technical Data Sheet 1-C-PUR-Adhesive Bonding of materials with different longitudinal extension must be assessed regarding their long-term behaviour, especially when they are exposed to fluctuating temperature ranges. The cured mass changes its colour due to UV radiation but not its strength in the cured bonded joint. Caution: the viscosity of the 1‑C‑PUR adhesives is approximately twice as high at +15 °C as at +25 °C. Skinning, joining times, as well as the required press and following processing times can only be determined accurately by selftests because they depend on material,...

Open the catalog to page 2

Technical Data Sheet 1-C-PUR-Adhesive Bonding of wood Bonding of larch: If larch is bonded outdoors, generally 1‑C‑PUR-adhesives may not be used. Substances, included in the wood or possibly generated, e.g. "Arabicum Galactan", considerably destroy/weak the bonding strength . No problems are known for PVAc- and EPOXI adhesives. If solid wood is bonded, the adhesive should preferably be applied on the two surfaces to be bonded. The press pressure shall be >1 N/mm². If solid wood is bonded for outdoor application, perform appropriate tests to achieve optimum bonding depending on wood type,...

Open the catalog to page 3All Weiss Chemie catalogs and technical brochures

-

COSMO®CL-300.140 SPECIAL

1 Pages

-

COSMO®HD-200.121

4 Pages

-

COSMO®HD-100.800

3 Pages

-

COSMO®HD-100.500

3 Pages

-

COSMO®HD-100.480

3 Pages

-

COSMO Adhesives

9 Pages

-

COSMOPU-190.110

3 Pages

-

COSMOPU-100.200

3 Pages

-

COSMOPU-100.250

3 Pages

-

COSMOPU-100.110

3 Pages

-

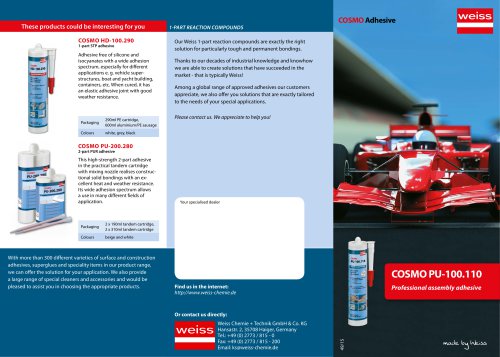

COSMO PU-100.110

2 Pages

-

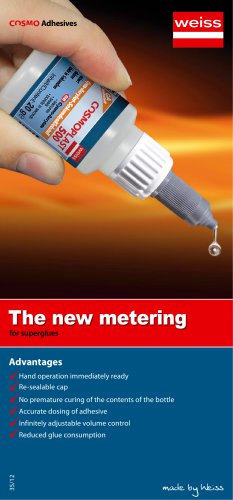

Cyanoacrylate Instant Glues

2 Pages

-

Airtight Bonding

20 Pages

-

COSMO ENERGY

2 Pages

-

COSMO Composite panels

2 Pages

-

Focus on Weiss

17 Pages

-

facade_elements

8 Pages

-

film lamination technology

2 Pages

-

COSMO Sandwich elements

2 Pages

-

beidseitig ALU, XPS-Kern

1 Pages

-

COSMO SL-660.110

3 Pages

-

COSMO CA-500.200

3 Pages

-

COSMO CA-500.170

3 Pages

-

COSMO CA-500.140

3 Pages

-

COSMO-ENERGY

2 Pages

-

Composite panels

2 Pages

-

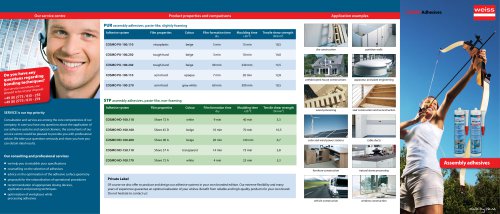

Assembly adhesives

2 Pages

-

COSMO FOAM - Composite panel

2 Pages

-

COSMO PU-100.200

2 Pages

-

PUR adhesives (1-part)

2 Pages

-

Adhesives for airproof bonding

16 Pages

-

CA adhesives

2 Pages

-

Facade elements

8 Pages

-

COSMO CA-500.120

3 Pages

-

COSMO CA-500.110

3 Pages

-

Composite panel

2 Pages

-

COSMOPLAN S

2 Pages

-

Window - Door - Façade

2 Pages

-

Cleaning & Care Service Sets

2 Pages

Archived catalogs

-

COSMO Sandwich elements 2018

2 Pages