Catalog excerpts

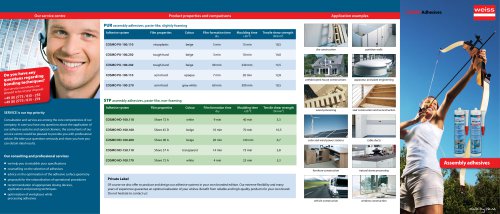

Technical Data Sheet 1-C-PUR-Assembly adhesive Examples for Application Special Properties ▪ Window and door construction ▪ tough-elastic adhesive joint ▪ Stair construction and building trade ▪ With many assembly bonding processes ▪ Thixotropic, does not drop off ▪ Automotive and vehicle body manufacturing ▪ Expands (foams) during the curing process! ▪ Diverse industrial fields ▪ Particularly fast reaction time ▪ Fast and homogeneous, full hardening ▪ Good adhesion characteristics to several types of wood, and building material, ceramics, metal, duroplast and thermoplastic after appropriate preparation of the surface. ▪ Good bonding strength at heat ▪ Good weather-proofness ▪ Can be over-coated with many paint systems ▪ Can be ground when hard-dry ▪ Low flame-spread characteristics when hard-dry Certificates / Test reports BG Verkehr, Dienststelle Schiffssicherheit / Ship Safety Division Approved for the application on ships in accordance with module B Approval No.: 118131-03 Applied quantity: max 230 g/m2 * year of manufacture The fire test as per IMO FTPC and approval of the system COSMO PU-100.200 were executed without pre-treatment of the surfaces to be glued with COSMO primers. French VOC-Emission class A+ Technical Data Basis Colour hard-dry medium viscous-pasty Skinning time - wet at +20 °C, sprayed with water; applied quantity 500 μm-PE/ PVC Functional strength depending on application at +20 °C Curing time at +20 °C, 50 % r. H. until it reaches the final strength Applied quantity depending on carrier material Processing temperatures adhesive and substrates Weiss Chemie + Technik GmbH & Co. KG Hansastraße 2 D-35708 Haiger

Open the catalog to page 1

Technical Data Sheet 1-C-PUR-Assembly adhesive General Information Paint the bonded workpieces only after the adhesive has cured completely; if they are painted too early, formation of paint bubbles cannot be excluded. If permanent humidity impact is expected, the bonded joints/bonded surfaces must additionally be sealed/protected using a "suitable sealant". Bonding of materials with different longitudinal extension must be assessed regarding their long-term behaviour, especially when they are exposed to fluctuating temperature ranges. The cured mass changes its colour due to UV radiation...

Open the catalog to page 2

Technical Data Sheet 1-C-PUR-Assembly adhesive Bonding of wood Bonding of larch: If larch is bonded outdoors, generally 1‑C‑PUR-adhesives may not be used. Substances, included in the wood or possibly generated, e.g. "Arabicum Galactan", considerably destroy/weak the bonding strength . No problems are known for PVAc- and EPOXI adhesives. If solid wood is bonded, the adhesive should preferably be applied on the two surfaces to be bonded. The press pressure shall be >1 N/mm². If solid wood is bonded for outdoor application, perform appropriate tests to achieve optimum bonding depending on wood...

Open the catalog to page 3All Weiss Chemie catalogs and technical brochures

-

COSMO®CL-300.140 SPECIAL

1 Pages

-

COSMO®HD-200.121

4 Pages

-

COSMO®HD-100.800

3 Pages

-

COSMO®HD-100.500

3 Pages

-

COSMO®HD-100.480

3 Pages

-

COSMO Adhesives

9 Pages

-

COSMOPU-190.110

3 Pages

-

COSMOPU-180.150

3 Pages

-

COSMOPU-100.250

3 Pages

-

COSMOPU-100.110

3 Pages

-

COSMO PU-100.110

2 Pages

-

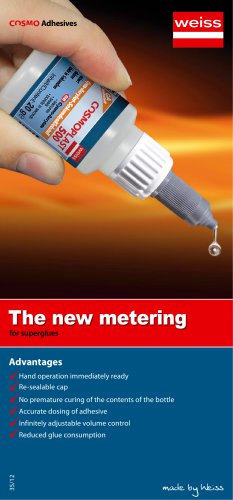

Cyanoacrylate Instant Glues

2 Pages

-

Airtight Bonding

20 Pages

-

COSMO ENERGY

2 Pages

-

COSMO Composite panels

2 Pages

-

Focus on Weiss

17 Pages

-

facade_elements

8 Pages

-

film lamination technology

2 Pages

-

COSMO Sandwich elements

2 Pages

-

beidseitig ALU, XPS-Kern

1 Pages

-

COSMO SL-660.110

3 Pages

-

COSMO CA-500.200

3 Pages

-

COSMO CA-500.170

3 Pages

-

COSMO CA-500.140

3 Pages

-

COSMO-ENERGY

2 Pages

-

Composite panels

2 Pages

-

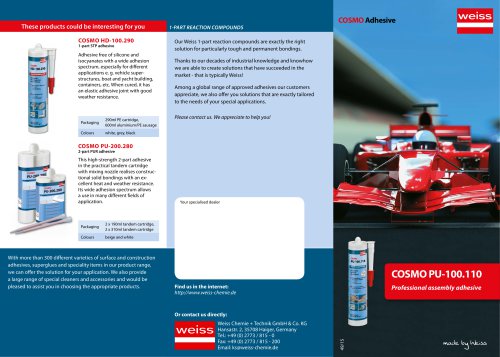

Assembly adhesives

2 Pages

-

COSMO FOAM - Composite panel

2 Pages

-

COSMO PU-100.200

2 Pages

-

PUR adhesives (1-part)

2 Pages

-

Adhesives for airproof bonding

16 Pages

-

CA adhesives

2 Pages

-

Facade elements

8 Pages

-

COSMO CA-500.120

3 Pages

-

COSMO CA-500.110

3 Pages

-

Composite panel

2 Pages

-

COSMOPLAN S

2 Pages

-

Window - Door - Façade

2 Pages

-

Cleaning & Care Service Sets

2 Pages

Archived catalogs

-

COSMO Sandwich elements 2018

2 Pages