Catalog excerpts

Technical Data Sheet Special Properties ▪ Used for bonding and sealing in automotive and vehicle body manufacture ▪ Skirting, laying of laminate and cable ducts ▪ Compatible with natural stone ▪ Stair construction and building trade ▪ Bonding of façades (cassette) - sandwich elements ▪ Glass bonding in furniture and display cabinet construction ▪ Good adhesion characteristics to different surfaces ▪ Surface can be smoothed well ▪ Apparatus and plant construction ▪ Compensates the expansion of different materials ▪ Diverse industrial fields ▪ Good weather resistance outdoors ▪ elastic adhesive joint ▪ Good UV-stability ▪ Can subsequently be powder-coated (annealing temperatures ≤ +200 °C) Certificates / Test reports GEV *Classified in the EMICODE class EC1 PLUS in compliance with the criterions of the GEV. Licence No.: 12410 French VOC-Emission class A+ Technical Data Basis Colour hard-dry Skin formation time - dry at +20 °C, 50 % r. H., applied quantity 500 μm-PE/PVC Curing time at +20 °C, 50 % r. H. until it reaches the final strength Operation temperature range -40 °C to +100 °C, temporary (powder coating) to +200 °C Processing temperatures adhesive and substrates Tensile shear strength as per DIN EN 1465, Alu/Alu, 0.2 mm joint at +20 °C Weiss Chemie + Technik GmbH & Co. KG Hansastraße 2 D-35708 Haiger

Open the catalog to page 1

Technical Data Sheet 1-C-MS-Adhesive General Information With increased air humidity or after the adhesive has been sprayed with water, the skinning time will be clearly shorter. Paint the bonded workpieces only after the adhesive has cured completely; if they are painted too early, formation of paint bubbles cannot be excluded. Bonding of materials with different longitudinal extension must be assessed regarding their long-term behaviour, especially when they are exposed to fluctuating temperature ranges. Skinning, joining times, as well as the required press and following processing times...

Open the catalog to page 2

Technical Data Sheet 1-C-MS-Adhesive For PVC-bonding, also read our technical information "Testing and evaluation of PVC-bonding with STP/MS adhesives of the product series COSMO® HD". Our user instructions, processing guidelines, product- and performance data, and other technical statements are only general directives; they describe only the condition of our products (values, determination of values on the date of completion) and the performances do not represent a warranty in the sense of § 443 BGB. Because of the wide variety of applications of the individual product and the relevant...

Open the catalog to page 3All Weiss Chemie catalogs and technical brochures

-

COSMO®CL-300.140 SPECIAL

1 Pages

-

COSMO®HD-200.121

4 Pages

-

COSMO®HD-100.800

3 Pages

-

COSMO®HD-100.500

3 Pages

-

COSMO Adhesives

9 Pages

-

COSMOPU-190.110

3 Pages

-

COSMOPU-180.150

3 Pages

-

COSMOPU-100.200

3 Pages

-

COSMOPU-100.250

3 Pages

-

COSMOPU-100.110

3 Pages

-

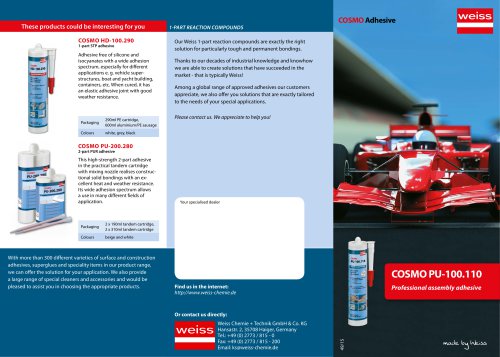

COSMO PU-100.110

2 Pages

-

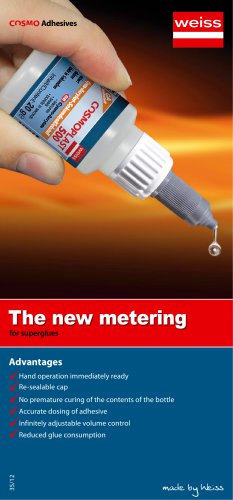

Cyanoacrylate Instant Glues

2 Pages

-

Airtight Bonding

20 Pages

-

COSMO ENERGY

2 Pages

-

COSMO Composite panels

2 Pages

-

Focus on Weiss

17 Pages

-

facade_elements

8 Pages

-

film lamination technology

2 Pages

-

COSMO Sandwich elements

2 Pages

-

beidseitig ALU, XPS-Kern

1 Pages

-

COSMO SL-660.110

3 Pages

-

COSMO CA-500.200

3 Pages

-

COSMO CA-500.170

3 Pages

-

COSMO CA-500.140

3 Pages

-

COSMO-ENERGY

2 Pages

-

Composite panels

2 Pages

-

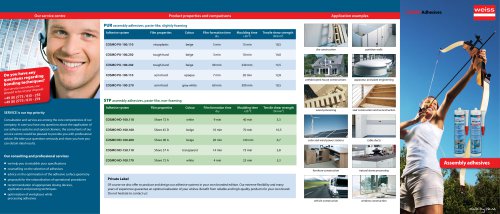

Assembly adhesives

2 Pages

-

COSMO FOAM - Composite panel

2 Pages

-

COSMO PU-100.200

2 Pages

-

PUR adhesives (1-part)

2 Pages

-

Adhesives for airproof bonding

16 Pages

-

CA adhesives

2 Pages

-

Facade elements

8 Pages

-

COSMO CA-500.120

3 Pages

-

COSMO CA-500.110

3 Pages

-

Composite panel

2 Pages

-

COSMOPLAN S

2 Pages

-

Window - Door - Façade

2 Pages

-

Cleaning & Care Service Sets

2 Pages

Archived catalogs

-

COSMO Sandwich elements 2018

2 Pages