Catalog excerpts

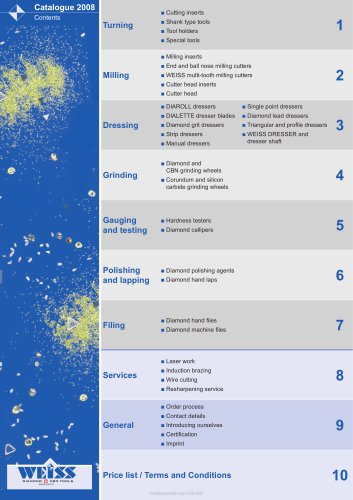

DIAROLL dressers Single point dressers DIALETTE dresser blades Diamond lead dressers Diamond grit dressers Triangular and prole dressers Strip dressers Manual dressers WEISS DRESSER and dresser shaft Diamond and CBN grinding wheels Corundum and silicon carbide grinding wheels Hardness testers Diamond callipers Diamond polishing agents Diamond hand laps Laser work Induction brazing Wire cutting Resharpening service Order process Contact details Introducing ourselves Cutter head Cutter head inserts WEISS multi-tooth milling cutters End and ball nose milling cutters Milling inserts Special tools Tool holders Shank type tools Cutting inserts Price list / Terms and Conditions Korrekturexemplar vom 14.08.2009

Open the catalog to page 1

Turning Chapter overview Overview and selection aid for cutting inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 Product selection by application / Cutting geometry / Cutting parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 Introduction to cutting materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Cutting inserts with BORAPACT (CBN) cutting edges Shank type tools overview . ....

Open the catalog to page 3

Cutting inserts Overview and selection aid Korrekturexemplar vom 14.08.2009 Overview of ISO indexable inserts with BORAPACT cutting edges Regrindable insert type Type in cutting edge design One way type — double-faced Solid insert Overview of ISO indexable inserts with diamond cutting edges Type in cutting edge design One way type — double-faced Regrindable insert type Solid insert Overview of Komet cutting inserts with diamond cutting edges Regrindable insert type Type in cutting edge design One way type — double-faced Solid insert © WEISS AG — Technical changes reserved

Open the catalog to page 4

Turning Selection by application | Cutting geometry | Cutting parameters Korrekturexemplar vom 14.08.2009 Grade overview High abrasion resistance, excellent impact resistance, exceptional quality and stability of cutting edges. Fine surface qualities, maximum heat resistance With carbide base, high abrasion resistance, good to very good cutting edge quality Without carbide base and without metallic binder phase, 99.9 % diamond content, notch-free cutting edges, maximum wear resistance, high thermal conductivity Synthetic, mono-crystalline diamond blanks, synthetic mono-crystal diamond,...

Open the catalog to page 5

Introduction to cutting materials Overview of cutting materials Korrekturexemplar vom 14.08.2009 Introduction Today's modern industrial society with its constant demand for increasingly newer and more progressive materials has made the metal machining industry reach new peaks. Improved production processes and the difculties resulting from the machining of new and progressive products lead to an increased demand for new shapes of cutting tools, which cannot be implemented by conventional materials, like highspeed steel, carbide, sintered metal and ceramic. Today, the manufacturing process...

Open the catalog to page 6

BORAPACT cutting edges BORAPACT (CBN) Korrekturexemplar vom 14.08.2009 BORAPACT (CBN) cutting materials Important notes for the use of BORAPACT (CBN) cutting materials Use only on machines with a high stability and sufcient drive power ■ Large cutting radius for increased impact resistance ■ Whenever possible, use negative cutting angles and a large tool setting angle ■ Fix tool holder as short as possible ■ Chamfered edges with additionally bevelled cutting edge increase edge stability for interrupted cut ■ Cutting inserts might break out if the machine is stopped during cutting or if the...

Open the catalog to page 7

Diamond cutting edges DIAPACT (PCD) Korrekturexemplar vom 14.08.2009 DIAPACT (PCD) cutting materials Important notes for the use of DIAPACT (PCD) cutting materials Do not measure cutting edges mechanically to avoid break-out risk ■ For interrupted cut, work with approx. half the cutting parameters ■ Intensive cooling with a light coolant emulsion will improve the cutting performance signicantly ■ For most applications, work with sharp cutting edges. Cutting edges should be bevelled by 0.025 mm for highly interrupted cuts and for roughing applications to prevent cutting edge break-out ■ A...

Open the catalog to page 8

Diamond cutting edges CVD diamond, MCD and natural diamond Korrekturexemplar vom 14.08.2009 CVD diamond cutting materials Important notes for the use of CVD diamond cutting materials Do not measure cutting edges mechanically to avoid break-out risk ■ For interrupted cut, work with approx. half the cutting parameters ■ Intensive cooling with a light coolant emulsion will improve the cutting performance signicantly ■ For most applications, work with sharp cutting edges. Cutting edges should be bevelled by 0.025 mm for highly interrupted cuts and for roughing applications to prevent cutting...

Open the catalog to page 9

ISO designation Indexable cutting inserts Korrekturexemplar vom 14.08.2009 Indexable cutting inserts ISO code Tolerance with- Incircle tolerance Ød out radius m [mm] [mm] Standard Clearance angle F Rhomboid 50° G Rhomboid 45° M Rhomboid 86° Other O clearance angles Clearance angle Hole with hole with hole with hole with hole with hole with hole with hole with hole with hole with hole with hole without hole without hole without hole Chip Hole conguration breaker Cylindrical hole + Countersink (40°~60°) Insert type Cylindrical hole + Countersink (40°~60°) without radius singlefaced...

Open the catalog to page 10

ISO designation Clamping tool holders and boring bars Korrekturexemplar vom 14.08.2009 Clamping tool holder ISO code C Clamping system Shank cross-section Height (h) and width (w) 60 Indexable cutting insert size 160 Insert clearance angle special design Tool type Insert shape Clamping tool holders Boring bars, ISO code A Tool holder with internal coolant supply, Steel shank Tool holder with internal coolant supply, Carbide shank Steel shank Shank design Boring bars Tool type Clamping system Indexable cutting insert size Incircle [mm] Insert clearance angle Insert shape Carbide shank ©...

Open the catalog to page 11All WEISS AG catalogs and technical brochures

-

Sommer June / July 2013

4 Pages

-

Newsletter 05/2012

2 Pages