Website:

WEIMA Maschinenbau GmbH

Website:

WEIMA Maschinenbau GmbH

Catalog excerpts

<§> HORIZONTAL SHREDDERS MULTI-SHAFT SHREDDERS GRANULATORS CRUSHERS

Open the catalog to page 1

Page 05 Page 06 Page 11 Page 16 Page 26 Page 42 Page 52 MISSION APPLICATIONS MACHINES Horizontal shredders Multi-shaft shredders Granulators Crushers SERVICE

Open the catalog to page 3

The family business. The young entrepreneur and visionary, Peter Rössler, recognized the potential of waste recycling early on and founded Weinsberg Maschinenfabrik – or WEIMA for short – in 1980. After the turn of the millennium, Martin Friz succeeded in bringing about the generation shift and has now been running the business since 2003. Global leader. WEIMA produces more than 1,200 shredders, briquetters and drainage presses per year on a production area of approx. 65,000 sqm with more than 300 employees worldwide. Since its foundation, about 40,000 machines have been delivered...

Open the catalog to page 5

REDUCE. REUSE. RECYCLE. WEIMA stands for active environmental protection and for robust shredding technology that’s “Made in Germany”. Our machines lay the foundation for a resource-saving future and are at the beginning of many recycling processes. AN APPRECIATION FOR WASTE MATERIALS As a recycling specialist, we see it as our duty to contribute to a clean planet. WEIMA shredders, granulators, briquetting and drainage presses are thus becoming ever more sophisticated, productive, and above all – energy-efficient. SUSTAINABLE FOR INDUSTRY AND TRADE The wide selection of machines and options...

Open the catalog to page 7

SHREDDING TECHNOLOGY At WEIMA you get everything from a single source: planning, design, machine, control cabinet, control, software, conveyor technology, support, maintenance, wear parts and spare parts. We make all this and much more possible with 40 YEARS OF RECYCLING KNOW-HOW.

Open the catalog to page 8

Plastics With many thousands of plastic shredders delivered, there are hardly any applications that we have not already processed. These include classic items such as purge, crates, pallets, pipes, containers, molded parts, and post-consumer waste such as PET bottles or packaging. But also particularly tear-resistant materials such as rubber or films made of BOPP, as well as fabrics and fibers made of aramid, Kevlar or carbon. “With the high volumes of plastic waste in the world, sustainable disposal concepts are particularly important, and shredding is the foundation for this.” Gunter...

Open the catalog to page 11

Wood If you want to generate energy from your waste in an environmentally friendly way, you can't do without wood as a raw material. The wood waste, which is shredded into chips, can be used for direct heat generation in wood burning oven or for the production of briquettes. Typical applications are all kinds of hard and soft woods, old wood, OSB and MDF scraps, veneer, plywood, stairs, doors, and pallets. And don't worry. Their nails and screws are simply shredded as well. Later they can be conveniently separated by means of a magnet. "The first WEIMA shredders of the 1980s were used for...

Open the catalog to page 12

50 Tons This is the throughput achieved by a WEIMA single-shaft shredder in the production of high-quality refuse-derived fuel. Waste and substitute fuel WEIMA is a full-range supplier for the single-stage as well as multi-stage processing of all types of waste. Robustly designed pre-shredders and secondary shredders effortlessly shred industrial and commercial waste, municipal waste, as well as bulky and household waste. The output material is ideal to produce highcalorific refuse-derived fuel (RDF). DID YOU KNOW? In Germany, the recycling rate for aluminum beverage cans is a whopping 99%....

Open the catalog to page 13

PORTFOLIO SHREDDERS When it comes to diversity, no one can beat us. With approx. 1,200 machine solutions delivered per year, we rely on a comprehensive shredding portfolio consisting of single-shaft shredders, multi-shaft shredders, granulators and primary crushers. We always have one goal in mind: to build the right machine for our customer. ONE SIZE FITS ALL? OFF-THE-SHELF MACHINES? NOT AT WEIMA.

Open the catalog to page 14

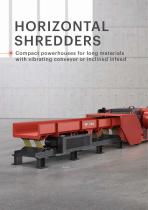

HORIZONTAL SHREDDERS <§) Compact powerhouses for long materials with vibrating conveyor or inclined infeed

Open the catalog to page 16

OPERATING PRINCIPLE HORIZONTAL SHREDDERS The biggest difference between classic shredders and horizontal shredders is the material infeed. Instead of a hydraulic ram, an extra-long vibrating conveyor is used – with a decisive advantage: It is ideal for feeding particularly long waste such as strips, battens, squared timber, profiles, pipe material, or other linear waste. While horizontal shredders are usually placed next to the machine and can be fed manually, they come with everything necessary for fully automated production operation. They are extremely compact and robustly built. These...

Open the catalog to page 18

Feeding of the material via inclined infeed (Beaver) or vibrating conveyor Feeding of the material to the rotor by means of an infeed roller Definition of particle size via screen Size reduction with rotor and counter knife Discharge of the shredded material by suction or screw auger

Open the catalog to page 19

<§) TECHNICAL HIGHLIGHTS Optimal shredding results with energy-efficient Siemens PLC control system The Siemens PLC control system installed in the separate control cabinet regulates all processes of a horizontal shredder and can be individually configured for each application. This guarantees consistently high-quality throughput material of homogeneous size - ideal for further processing. If required, horizontal shredders can of course also be integrated into a fully automatic production line. via electric motor and V-belt Oversized scrap? No problem. Extra-large shredders Long or wide...

Open the catalog to page 20

ROBUST MACHINE DESIGN including offset rotor bearings WEIMA horizontal shredders are not only particularly compact, but above all, robustly built. Rotor bearings that are offset from the machine frame are insensitive to dust, easy to maintain and durable.

Open the catalog to page 21

thanks to exchangeable screen with round holes Screwed underneath the rotor is a round hole screen, which can be replaced as required by a screen with a larger or smaller hole diameter in the range 10 - 80 mm. Material is shredded by the rotor until it fits through the hole openings, falls through, and is finally suctioned off. This guarantees a particularly homogeneous material for each individual requirement. Achieve high throughput rates with innovative V rotor and feed roller The cutting geometry of a shredder has a significant influence on the shredding result and the output quantity....

Open the catalog to page 22All WEIMA Maschinenbau GmbH catalogs and technical brochures

-

WEIMA Single-shaft shredders

76 Pages

-

WL 4 | Single-shaft shredder

8 Pages

-

C series | Briquette presses

8 Pages

-

WL 6 | Single-shaft shredder

8 Pages

-

WL 4 | Single-shaft shredder

8 Pages

-

WL 8 | Single-shaft shredder

8 Pages

-

WL 4 | Single-shaft shredder

8 Pages

-

HD 500 | HD 700K | HD 1500

4 Pages

-

TH 1500 | TH 2800 | TH 3400

5 Pages

-

TH 3400 – Briquette Press

5 Pages

-

C 140 – Briquette Press

4 Pages

-

SPIDER HRS-SERIES

8 Pages

-

Series WSM Granulators

2 Pages

-

WLK

5 Pages

-

Briquetting presses

8 Pages

-

Series WT

2 Pages

-

Granulator

2 Pages

-

Four-shaft shredder

2 Pages