Catalog excerpts

Stainless Steel Rotary Control Valve For hydraulics in a harsh environment. The 280 series of high-pressure stainless steel hydraulic rotary control valves are the ideal solution for control of hydraulic actuators used in arduous environments where internal leakage must be minimised. The valves utilise an optically flat rotary spool with pressure loaded seats, to ensure either zero or near zero leakage (depending on flow size). Maximum Pressure: Up to 700 bar Maximum Flow: Up to 38 lpm Operating Temperature: Ambient temperature -20 to 40’C Fluid temperature 20 to 80’C Porting: BSPP, NPTF, SAE, & Manifold (See Table 2, ordering codes) Material: Steel components in 316 Stainless Steel Body. NBR Seals. Weight: Typically 3.2 kg Mounting: Standard – 4 x 5/16” UNC holes to fasten screws into valve base Panel – 4 x 5/16” UNC studs to fasten valve into panel Manifold – 4 x 5/16” UNC through bolts to fasten valve onto manifold Milwaukee, WI 53235, USA Tel: +1 (414) 769-6400 sales-us@webtec.com St. Ives, Cambs. PE27 3LZ, UK Tel: +44 (0) 1480 397 400 sales-uk@webtec.com Features l Over 4000 possible configurations l 3 position / 2 position l 4 port / 3 port l Zero leakage (15 lpm version) l Standard documentation: l Manual l Certificate of Conformity l Performance test Certificate l Declaration of Conformity to ‘ATEX’ l BS EN13463-1:2009 (ATEX) rating of ‘II 3G TX’ l CETOP 03 / NFPA D03 / DIN NG06 / mounting adaptor l Option of manufacture to EN10204-3.1 Hydraulic measurement and control

Open the catalog to page 1

Ordering Codes Typical Code Valve Model (Table 1) Porting (Table 2) Flow Size (Table 3) Valve Options (Table 4) Position Type (Table 5) Port Type (Table 6) Code Symbol Port size Manifold mount BS ISO 3601 (AS568A) 014 O’ ring. *1 All NPTF threads are to ANSI B1.20.3 -1976 Class Typical Pressure Drop Curve # 1. As stated in the standard it is recommended that “sealing is accomplished by the means of a sealant applied to the thread”. NPT fittings may also be used to connect to NPTF ports (also with a sealant applied to the thread) Table 3: Flow Size Code Maximum Maximum Pressure Interflow...

Open the catalog to page 2

Leakage across paths of the 280 Series Valve. The 280 valve has been tested to ISO5208:2008(E) and been rated as follows Flow size 0 is rated at ‘A’ i.e. no visible leak for the duration of the test. Flow sizes 1 & 2 are rated at ‘B’ i.e. maximum allowable leakage 0.003ml/s (0.00018In3/s) equivalent to 1 drop of water every 10 minutes. Interflow is a transient effect that occurs on flow size 1 & 2. It occurs as the valve is operated between positions. During this time a small flow from ports A, B and P to port T is possible, which can cause the pressure of lines A, B or P to drop slightly....

Open the catalog to page 3

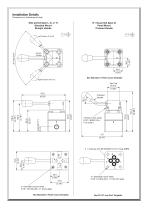

Installation Details Dimensions in millimetres (Inches) Side ported (type L, E, or T) Standard Mount Straight Handle O’ ring ported (type A) Panel Mount Cranked Handle Centre Position 35.0 (1.38”) See Standard / Panel mount template Cranked Handle 4 Panel mount studs. 5/16”-18UNC-2A x 14.2 (0.56”). 4 x C/bores with BS ISO3601-014 O’ rings (NBR) B 4 x Standard mount holes 5/16”-18 UNC-2B x 11 (0.43) deep See Standard / Panel mount template 4 x Standard mount holes 5/16”-18 UNC-2B x 11.0 (0.43”) deep See 014 O’ ring Port Template

Open the catalog to page 4

Installation Details Dimensions in millimetres (Inches) 280 port type C with 280-CETOP3 Kit O’ ring ported (type C) Manifold Mount Straight Handle Some dis assembly / assembly is required for installation. See manual for further details. 4 x 5/16”-18UNC, manifold mount through bolts A 4 x C/bores with BS ISO3601-011 O’ rings (NBR) See 014 O’ ring port template Standard / Panel Mount Template CETOP3 pattern Perimeter of valve with adaptor Standard or panel mount holes:: Ø8.2 (0.32”) x 4 Posn’s Equi-spaced on pitch circle diameter 67.3 (2.65”) 014 O’ ring Port Template A P Manifold Holes:...

Open the catalog to page 5All Webtec catalogs and technical brochures

-

HPM110Digital pressure gauge

3 Pages

-

HPM7000Hydraulic Data Logger

3 Pages

-

FDC140

3 Pages

-

GF series

3 Pages