Catalog excerpts

Vacuum Chamber Machines Chamber Belt Machine Ideal for any Size Operation Advanced Vacuum Packaging Systems

Open the catalog to page 1

Vacuum Chamber Machines Clearly Advantageous: The Chamber Belt Machine Advanced Vacuum Packaging Systems

Open the catalog to page 2

Highly versatile Flexibility is key when vacuum packaging food and non-food products. Our vacuum chamber packaging machine is highly versatile and handles a wide variety of product sizes and shapes. Vacuum packaging not only results in a nice retail appearance, but also improves your profitability. Our Chamber Belt Machine WBM 1350-II is the ideal solution for any size production plant where a broad range of products are being packaged under vacuum. No matter what you’re packaging, you can count on perfect side seal seams when using our WBM 1350-II. And, it’s an ideal tool for those wanting...

Open the catalog to page 3

Vacuum Chamber Machines The WBM 1350-11: One machine serves multiple uses. Advanced Vacuum Packaging Systems

Open the catalog to page 4

Inline or stand-alone vacuum packaging. More capacity, more flexibility, more security. Our automatic Chamber Belt Machine WBM 1350-II is engineered to the highest quality standards, including corrosion resistant materials, a rapid final vacuum, high sealing pressure, strong performance and an especially spacious chamber. Highlights of the new machine version: The TCH-II sealing system regulates the sealing temperature for precise, absolute sealing strength. Overheating is avoided due to the machine’s precise temperature control mechanism. No cooling water required. The bi-active sealing...

Open the catalog to page 5

Vacuum Chamber Machines Secure seals: Our intelligent Thermo Controlled Heat Sealing System (TCH-II) guarantees secure sealing results. Optimum sealing temperatures are reached through constant and precise control. Overheating of the seal bars and the packaging material is avoided due to the precise temperature regulation. Sealing parameters for the TCH-II and reliable bi-active sealing can be adjusted according to the packaging material. Powerful performance: Two temperaturecontrolled sealing transformers supply the exact energy required. The transformers provide the right and left sealing...

Open the catalog to page 6

Waste handling: An optional trim removal and collection system rounds out our vacuum chamber packaging machine. It features an automatic cutting system that trims the excess material while the product is held tightly in place (via flexible expanders and spring powered pins) and then disposes the material into a 120-liter stainless steel container. Solid construction: Hardened stainless steel shafts and ball bearings result in an absolute zero clearance lid guide of the chamber along with solid construction for a long life. Conveyor belt loosens with the push of a button: When it comes time...

Open the catalog to page 7

Vacuum Chamber Machines Inline Efficiency: Compatible with any production line: Our high-capacity WBM 1350-11 is the ideal packaging machine for any shrink packaging application. completes any shrink packaging line, featuring ourShrinkTunnel STCW, Dryer DU, variable Conveyor Belts CB, Product Depot PD or It is also possible to integrate the chamber belt machine and other shrink line components into your production flow and to adjust the machines to the level of desired production. Based on your production reguirements, our shrink line can also be designed for those layouts that reguire a...

Open the catalog to page 8

Above: Inline shrink packaging, featuring our Chamber Belt Machine WBM 1 350-II, Conveyor Belt CB 80, ShrinkTunnel At Left: Product guide in 90° angle, featuring our Chamber Belt Machine WBM 1350-II, Conveyor Belt CB, ShrinkTunnel STCW, Dryer DU and Product Depot PD. Also available with a right-angled installation are smaller units with 60 cm wide conveyor belts.

Open the catalog to page 9

Vacuum Chamber Machines WBM 1350-II Chamber Belt Machine Technical Data Drive: Control: Touch screen: External dimensions: Chamber dimensions: Weight: Seal bar length: Cooling water: Max. product length: Max. product height: Electric: Fuse: Compressed air: Packaging capacity: Stainless steel drum motor, 0.63 or 1.0 m/s (depending on the requirement), IP 67 PLC Mitsubishi FX (with optional remote diagnosis) 12" full-colour touch screen, high resolution, IP 67 3,748 x 1,540 x 2,400 mm (W x D x H) 1,400 x 1,050 x 250 (W x D x H) 2,200 kg 1,350 mm each side not needed 750 mm 250 mm 400 V, 50...

Open the catalog to page 10

WEBOMATIC has been developing vacuum packaging machinery for more than 50 years. High-quality technology made in Germany WEBOMATIC machines have successfully proven their values worldwide in almost all areas of packaging, especially if the optimum vacuum packaging of easily perishable food, sterile cosmetic and medical equipment or high sensible industrial products is concerned. Convincing product features first-class processing high-quality materials and components easy operation longevity reliability servicefriendly Small and big solutions. For workshops and industry, for the food and...

Open the catalog to page 11

Maschinenfabrik GmbH Hansastr. 119 44866 Bochum/Germany © WEBOMATIC 03/2009. All rights reserved.

Open the catalog to page 12All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

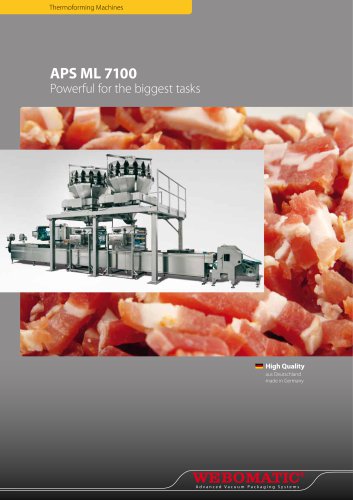

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages