Catalog excerpts

Automatic, Flexible and Highly Efficient Advanced Vacuum Packaging Systems

Open the catalog to page 1

Function diagram traysealers: automatic tray liguid products unwinding system inside the sealing station the trays are b) MAP packaged under vacuum or c) vacuum skin packaged. A cut-off knife then separates the package from the film. with a snap lid oran easy-to-peel label Advanced Vacuum Packaging Systems

Open the catalog to page 2

Enormous versatility. Enhanced product appearance! variables for protection and keeping shelf-life - MAP packaging under vacuum or - vacuum skin packaging individual preference: can utilize all hot sealable top films and trays consumer convenience: easy opening by means of optional peel flap or corner Fit for (non-)food: sealed trays The versatility of tray packaging is enormous. Trays are always a first choice in the market- place to safely present fresh products using a method that maintains freshness and extends Consumers prefer attractive, well-presented tray-packed products along with...

Open the catalog to page 3

Traysealers Flexible Traysealers! optional lidding applicator for easy accessible chamber area simplifies reclosable packages positioning of film, tooling change overs and enables thorough cleaning

Open the catalog to page 4

Our fully automatic traysealers offer an all-around highly flexible solution for variety of tray formats, materials, and production capacities. With our broad line, we surely have the appropriately sized machine and accessories for any tray packaging need. consequent CleanDesign Due to the modular design and a variety of optional features our fully automated traysealers can be adapted over time to meet future needs. With upgrades such as a denester, filling system, dosing system, coding or inline labeling systems, or a lid applicator, one can achieve higher production capacities with a...

Open the catalog to page 5

Fully automated traysealer Advanced Vacuum Packaging Systems

Open the catalog to page 6

Perfect for small formats Our fully automated industrial-sized TL500/ TL500-duo is designed for high production capacities and is engineered to handle a wide variety of food packaging applications and volumes. Depending on the tray size, ourTL500 models can seal up to 60 trays per minute (duo-version: more than 100) and can handle a variety of tray sizes up to 510 x 280 mm and maximum tray height of 120 mm. Most tray sealers in the industry are simply designed for MAP and basic vacuum packaging; however, ourTL500s feature our hygienic CleanDesign.This solid machine is perfectly designed for...

Open the catalog to page 7

Fully automated traysealer Advanced Vacuum Packaging Systems

Open the catalog to page 8

TL 1100 in cleaning position: open design featuring slidable and ti Ita ble covers precise tray positioning by fiber-optics reliable performance With its huge sealing chamber, ourTL 1100 offersan extreme amount of space and economically seals up to 5,000 trays per hour, TheTL 1100 also features our CleanDesign including angled surfaces to allow water run-off and prevent water and dirt from accumulating from the first day the machine enters produc- The unigue open design makes sanitation and maintenance guickand easy and is proven through our movable and tiltable protective covers on the...

Open the catalog to page 9

Fully automated traysealers TL500 Technical data: tray materials: possible tray configurations for standard trays (further die set configurations upon reguest) PP, PS, A-PET, C-PET, EPS, paper, cardboard, aluminum Sealing die set each complete with contour cutting (outside-cut) color touch-screen: cycle capacities: sealing variants: (compare photos external dimensions: film transport: film reel diameter: connected load: depending on eguipmentand product peeling flap wxdxh, closed depending on optional features special voltage optional 4 kW (plus vacuum pump) 4 kW (plus vacuum pump) vacuum...

Open the catalog to page 10

13 kW (plus vacuum pump) central vacuum » = standard equipment O = option ©WEBOMATIC 04/2010. All rights reserved. WEBOMATIC has been developing vacuum packaging machinery for more than 50 years. High-quality technology made in Germany WEBOMATIC machines have successfully proven their values worldwide in almost all areas of packaging, especially if the optimum vacuum packaging of easily perishable food, sterile cosmetic and medical eguipment or high sensible industrial products is concerned. Convincing product features • first-class processing • high-guality materials and components • easy...

Open the catalog to page 11

Maschinenfabrik GmbH ©WEBOMATIC 04/2010, All rights reserved WWW.WebomatiC.de

Open the catalog to page 12All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

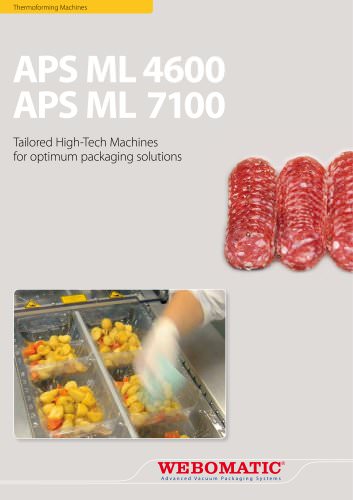

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

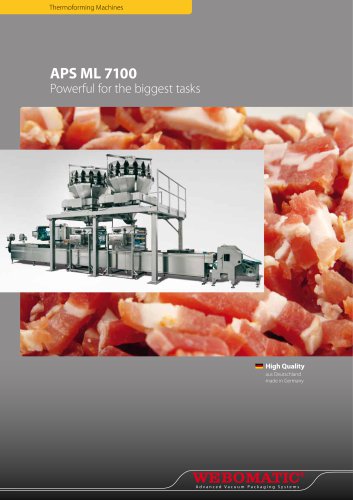

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages