Catalog excerpts

THERMOFORMING MACHINES Individual packaging solutions for unique products.

Open the catalog to page 1

For trade, craft and industry. Although today WEBOMATIC is a multinational family business, we have not forgotten our roots and traditions. Since 1958 WEBOMATIC is the ideal partner for small, medium and industrial sized companies. Whether you want to pack food products (e.g., fresh and processed meat, dairy products, convenience meals, fresh or pickled vegetables, pasta, fish, frozen foods, etc.) or non-food products (e.g., sterile pharma goods or cosmetics), WEBOMATIC offers a wide range to pack your product in thermoforming machines. Our thermoforming machines are individually tailored...

Open the catalog to page 2

Available range Thermoforming Machines Food, Non-Food Food, Non-Food Food, Non-Food Food, Non-Food Size / capacity Packaging shape variants freely definable freely definable freely definable Packaging style Protrude-skin, Form shrink, 2pack (max. 300 mm also with pre-heating) Index/Repeat length § Draw depth Bottom film width Bottom film: Flexible film Rigid film Flexible film Rigid film

Open the catalog to page 4

WEBOMATIC CleanDesign® WEBOMATIC Sealing Technology Forming procedures Optional: compressed airand vacuum, plug assist forming vacuum, plug assist forming vacuum, plug assist forming vacuum, plug assist forming Optional: Zigzag cut, Perforation cut, Optional: Zigzag cut, Perforation Optional: Zigzag cut, Perforation Optional: Zigzag cut, Perforation Round corners, Squeezing knife cut, Round corners, Squeezing cut, Round corners, Squeezing cut, Round corners, Squeezing knife, Strip punch, Contour or knife, Strip punch, Contour or knife, Strip punch, Contour or Film rewinding with dancer arms...

Open the catalog to page 5

Thermoforming Machines

Open the catalog to page 6

WEBOMATIC thermoforming machines are based upon four models that are individually designed for each customer’s needs and products. They reflect state-of-the-art technology in material, constructions, equipment and design so that with the modular machine system, the thermoformers can be tailored to specific customer requirements. This modularity applies to the outer dimensions, the variable infeed zone as well as specialised equipment and complex automation options. Adjustable infeed zones for manual or fully automatic loading, variable discharge modules for the optional use of coding and/or...

Open the catalog to page 7

Our industrial thermoforming machines are ideally suited for the multi-shift operation and offer stateof-the-art technology while being durable and robust. The consistent WEBOMATIC CleanDesign® ensures all requirements of a time-saving hygienic cleaning in-between productions shifts and afterwards. Further, no end is set to distinctive packaging designs with WEBOMATIC thermoforming machines. On demand, our machines can produce vacuum, MAP, shrink or skin packaging, which can be adapted to the product through various packaging options. So there are e.g. options for optimal placement on...

Open the catalog to page 8

In the forming station the bottom ready for further transport transported forward film is heated and formed and optionally enhanced by metal detectors, labelers, or others. The filled packages are: ● evacuated and sealed ● evacuated, map treated and sealed Longitudinal cutting of the package

Open the catalog to page 9

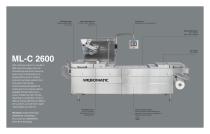

Compact entry machine Low space requirements and full-line compatibility Flexible and rigid films Films up to 422 mm of width, repeat length up to 300 mm J^VKOaBJl »3«acrs^ *ibdn"5^ ■IU'NI’^« -'LTVHOlISy, «W3"s^

Open the catalog to page 10

Packaging types: Sealing, vacuum, MAP, skin, shrink Control unit: Mitsubishi PLC, touch screen 8,4 Repeat length/Index: 120 - 300 mm (also with pre-heating) < ML-C 2600 With a total size of just 3.7 m, the ML-C 2600 marks the compact entry into thermoforming and fits into nearly any place of use. This thermoformer is ideally suited for small or medium production and allows operation from both sides of the machine. Should preheating be applied, the loading zone is not reduced, optional pluggable forming inserts allow a product change-over within minutes. Depending on specification, the ML-C...

Open the catalog to page 11

ML-C 3600 Modular design with length up to 15 m to fulfill starting automatization requirements Flexible and rigid films, even optional top film forming Films up to 462 mm of width, repeat length up to 400 mm Labels optionally on both top and bottom film Support jumbo rolls for the bottom film in straight line or at 90° angle

Open the catalog to page 12

Packaging types: Sealing, vacuum, MAP, skin, shrink Machine dimensions: Length: 4.500 – 15.000 mm Width: 1.130 – 1.190 mm Height: 1.980 mm (± 35 mm) Control unit: Mitsubishi PLC, touch screen 8,4" Repeat length/Index: 120 – 400 mm (400 mm pre-heated) precisely according to your packaging specifications and is perfectly fit for medium productions and prepared for plenty of extra options. The machine length can be extended from an economic 4.5 m up to a stately 15 m. Depending on specification, the ML-C 3600 can process rigid films up to 600 µm with a width of up to 462 mm in repeat lengths...

Open the catalog to page 13

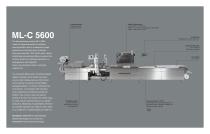

ML-C 5600 Industrial capacities and modular design with extendable length up to 20 m Flexible and rigid films, even optional top film forming Processes film width up to 562 mm, repeat length up to 600 mm Optimal distribution of power and grip by double knee lever system High degree of customization

Open the catalog to page 14

Packaging types: Sealing, vacuum, MAP, skin, shrink Machine dimensions: Length: 5.260 – 19.500 mm Width: max. 1.290 mm (depending on film width) Height: 1.980 mm (± 35 mm) Control unit: Mitsubishi PLC, touch screen 12" meets the highest demands for industrial Repeat length/Index: 220 – 600 mm (600 mm pre-heated) sized production while it is designed for large production environments and is suited for high-speed operation. With its film width, repeat length/index and optimized lifting movement, the machine is ideal for automated operation in a packaging line with integrated slicers,...

Open the catalog to page 15

ML-C 5600-skin Protrude-Skin packaging by full-surface sealing without modifying the shape or color of the product High puncture-safety guarantees the best possible protection against external influences (depending on film quality) Reduced use of materials for less resource consumption Max. draw depth of 70 mm for flat an exclusively looking packagings

Open the catalog to page 16All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

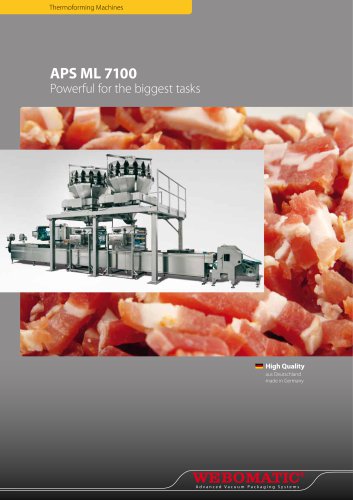

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages