Catalog excerpts

Shrink Units Shrinking STCW 60 / STCW 80 Drying DU 60 / DU 80 Transporting CB 60 / CB 80 Inline Shrink Equipment for Large/Industrial Size Operations

Open the catalog to page 1

Advanced Vacuum Packaging Systems

Open the catalog to page 2

The ideal solution for large packaging operations/long products: ShrinkTunnel STCW, Dryer DU and Conveyor Belt CB. Improving product appearance with shrink packaging: Packaging your food products in transparent shrink film eliminates wrinkles, resulting in an attractive and eye-catching appearance on the display shelf Visually appealing and always in excellent form. By combining your packaging eguipment with automatic ShrinkTunnel STCW, Dryer DU, and variable Conveyor Belts CB, you'll have a modern WEBOMATIC shrink packaging line that runs like Our fully automatic shrink tunnel and the mat-...

Open the catalog to page 3

Distinctly Different - Inside and Out Advanced Vacuum Packaging Systems

Open the catalog to page 4

The WEBOMATIC ShiinkTunnel STCWis designed with clever details which are simply unique, making a positive impression with all along the production line by delivering perfect shrinking results. The efficient flow of the shrink packages through the hot water cascades inside the STCW provides a constant, equal and wrinkle- free shrinking result. Without interrupting opera- ting cycle breaks the tunnel can easily handle an enormous packaging volume. No problems arise even being fed by several packaging machines. By means of the water temperature regulation the shrinking process is adapted in a...

Open the catalog to page 5

Shrink Units All around powerful drying application Advanced Vacuum Packaging Systems

Open the catalog to page 6

WEBOMATIC CleanDesign also inside:The conveyor belt can be easily removed while the machine hood is latched in its top safe position. Operating either independently or with our ideal choice for shrink lines with high produc- tion volumes. Ideal for automated operations Just like our shrink tunnel, the dryer operates continuously without interrupting cycle times, delivering the best performance and results you can count on. Perfectly wrapped shrink packages that have been dried with care can move immediately into weighing, labelling and boxing operations without interruption. Ultimate drying...

Open the catalog to page 7

Always reliable WEBOMATIC CleanDesign: Sloped surfaces and rounded edges as well as the position of the product guide ensure the best possible hygienic cleaning. Our WEBOMATIC Conveyor Belts CB complete any inline packaging operation. Depending on the working width of your inline packaging configuration, we offer conveyor belts in widths of 60 or 80 cm. Various belt lengths (1.5 to 7 m; in 50 cm increments) can also be specified. Clean design for improved sanitation Further added special features of our Conveyor Belts CB are the hygienic and cleaning aspects: Our WEBOMATIC CleanDesign...

Open the catalog to page 8

Always flexible Thermoforming Machine h li ne system includes a thermoforming machine, conveyor belt, s h rink tun nel, dryer and turntable LS 150 at the exit area. Chamber Belt Machine CB 80-150 STCW 80 Inline system includes a chamber belt machine, conveyor belt, shrink tunnel, dryer and product depot. Double Chamber Machine Compact inline system features a double vacuum chamber packaging machine, transfer to the conveyor belt by exit rollers, a shrink tunnel, dryer and product depot. Various combinations - rarely a problem Our new shrink packaging machines are a perfect match for any...

Open the catalog to page 9

Shrink Units Touch screen of ShrinkTunnel STCW Touch screen of Dryer DU Clever Automation More intelligence through a PLC interface. We draw on the highly intelligent Mitsubishi PLC to control our shrink tunnel and dryer in seguence with the balance of your packaging line. The easy-to-read touch screen and pre- programmed parameters is child's play. Different languages and user-friendly icons and error indicators are also made possible for various language-speaking workforces. The control also features a supervisor setting for top security of your product programs. If that's not enough, we...

Open the catalog to page 10

Automatic Shrink Tunnel STCW 60 and STCW 80 Technical Data external dimensions max. conveyor electr. control electric inmm(wxdxh) product height product speed heating unit inmm(wxh) weight capacity Technical Data model external dimensions max. max. conveyor in mm (w X d X h) product height product speed inmm(wxh) weight electr. control Technical Data model belt width total width standard lengths conveyor electric CB 60 550 660 from 1,5 m up to 7 m in 0,5 m steps, special lengths optional 0,20 m/s CB 80 750 860 from 1,5 m up to 7 m in 0,5 m steps, special lengths optional 0,62 m/s E =...

Open the catalog to page 11

Maschinenfabrik GmbH Hansastr. 119 44866 Bochum/Germany © WEBOMATIC 03/2009. All rights reserved. Telephone +49 (0) 2327-3099-0 Telefax +49 (0) 2327-3099-29 info@webomatic.de www.webomatic.de

Open the catalog to page 12All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

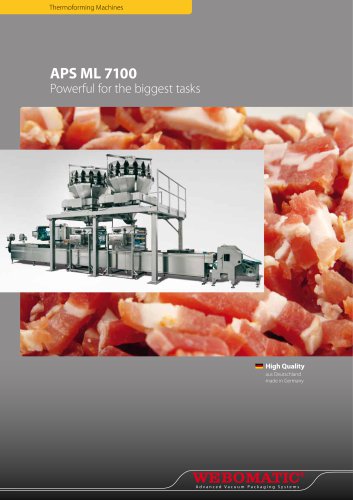

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages