Catalog excerpts

Thermoforming Machines ML-C 2600 ML-C 3600 ML-C 5600 Thermoforming technology in the CleanDesign Advanced Vacuum Packaging Systems

Open the catalog to page 1

Thermoforming Machines How the thermoforming process works: 8 Longitudinal cutting of the package occurs. Top film is unwound from the roll. The formed packages are transported forward. The packages are filled in the filling area. In the forming station the bottom film is heated and formed. In the sealing area the package is put under vacuum and, if necessary, modified gases (MAP) are added. The top film is now sealed to the bottom film by heat and pressure. Cross cutting of the package occurs. 1 Bottom film is unwound from the roll. 9 The finished packages are ready for further transport....

Open the catalog to page 2

ML-C 2600 Efficiency for compact spaces Compact, but with high-quality thermoforming technology nonetheless: the ML-C 2600 does not require much space. Left: Built in the CleanDesign. The cleaning mode allows a full wash down with covers removed. With a total compact size of just 3.7 m, the ML-C 2600 fits into nearly any place of use. The machine will pack your products quickly and cost-effectively with full-fledged thermoforming technology. The machine is equipped with a swivelling monitor that allows operation from both sides of the machine. Should preheating be applied, the loading zone...

Open the catalog to page 3

Thermoforming Machines ML-C 3600 The versatile all-round solution Modular and thereby versatile: the ML-C 3600 adapts to your production. The ML-C 3600 is built precisely according to your packaging requirements and specifications. The machine length can be extended from an economic 4.5 m up to a stately 10 m. This enables a generous loading zone, for instance, or the integration of a filling unit, labelling or coding systems. It goes without saying that the ultra-modern control synchronizes external modules with the thermoforming machine.

Open the catalog to page 4

Safe handling, and tool-less as well: The knife shaft for the longitudinal cutting is hidden in a cassette for the safety of the operational staff. The knives are also protected in the cassette. Servo-driven, the drive chain conveys the film most precisely until the pack is finished. The chain’s high gripping power safely supports even heavy products. For creating tailor-made superior thermo formed packs in large quantities, this machine is prepared for plenty of extra options. Among them are an extended loading zone, also knee-free, and an extended discharge. Another very important...

Open the catalog to page 5

Thermoforming Machines ML-C 5600 Packaging high-tech brought to perfection Ready for large production: the ML-C 5600 shown here is equipped with an optional labelling station. The thermoforming machine ML-C 5600 meets the highest demands for industrialsized production while it is designed for medium and large production environ ments and is suited for high-speed operation. With its web width, repeat index and optimized lifting movement, the machine is ideal for automated operation in a packaging line with integrated slicers, pick-and-place robots, multi-head weighers etc. Important...

Open the catalog to page 6

Elaborate construction: the top film unwinding system. It is equipped with a spreader mandrel for fixing the roll, a positioning sled for guiding the film, and a dancer arm which keeps the film under tension. The whole uncoiling is thus under control. The vacuum valves of the ML-C 5600 are placed directly at the die. This means even shorter ways to create the vacuum and adds up to a quicker production. Exclusive special equipment: A ML-C 5600 with a thermo transfer printer for labelling production data. As its smaller siblings, the ML-C 5600 is also built in the CleanDesign. The cleaning...

Open the catalog to page 7

Thermoforming Machines Details and special equipment Jumbo roll: an important prerequisite for uninterrupted production. Connected in a straight line, those rolls with little film remaining can be moved to the top support as standard equipment. Theses pages show the following special equipment: jumbo roll support, connected in a straight line strip punch a roller belt adjustable in height a travelling punch a and EBOMATIC 2pack: a combination of W a skin and MAP pack

Open the catalog to page 8

A strip punch allows you to produce packs with even and smooth ridges. WEBOMATIC 2pack: Our own development is a thermoforming pack with several chambers, some of which are skinned and others injected with modified atmosphere (MAP). This combination of two packaging types is exclusively offered by WEBOMATIC and unique in the packaging industry. With the jumbo roll support, operators can unlock the left carrier and fold it to the side, so that they can change the film roll even in limited spaces. Employing a roller belt that is adjustable in height prevents heavy products from sagging. Our...

Open the catalog to page 9

Thermoforming Machines Technical data Thermoforming Machine Family ML-C ML-C 2600 General Drive Vacuum pump servo drive, highly dynamic, electronically controlled built in up to 140 m3/h; bigger volumes external up to 10 cycles/min. (depending on machine equipment and product) Mitsubishi 5.7“ colour touch screen, rotatable and swivelling Packing performance Control Monitor Remote diagnosis / Communication module Measurements Length Width Height Repeat length / Index Draw depth Packing materials Width bottom film Bottom film Thermoformable and sealable flexible film Thermoformable and...

Open the catalog to page 10

servo drive, highly dynamic, electronically controlled built in up to 250 m3/h; bigger volumes external; roots pump on request up to 16 cycles/min. (depending on machine equipment and product) Mitsubishi 8.4“ hi-res colour touch screen, rotatable and swivelling, USB port servo drive, highly dynamic, electronically controlled built in up to 250 m3/h; bigger volumes external; roots pump on request up to 20 cycles/min. (depending on machine equipment and product) Mitsubishi 12.1“ hi-res colour touch screen, rotatable and swivelling, USB port Modular: 4,550 –10,000 mm 1,130–1,190 mm (depending...

Open the catalog to page 11All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

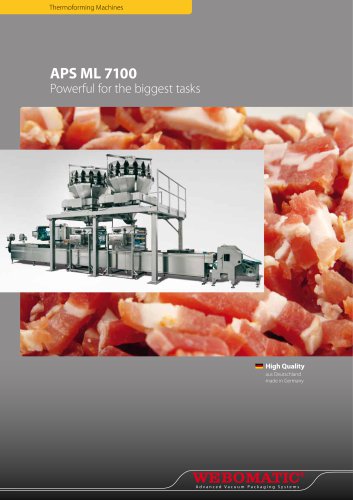

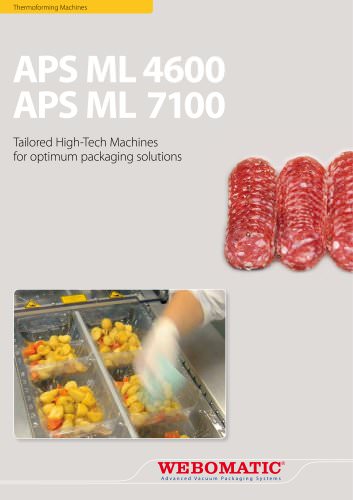

APS ML 7100_2013

8 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages