Catalog excerpts

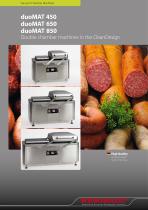

Vacuum Chamber Machines duoMAT 450 duoMAT 650 duoMAT 850 Double chamber machines in the CleanDesign Advanced Vacuum Packaging Systems

Open the catalog to page 1

Vacuum Chamber Machines Clear forms. Clear functions. The duoMAT is a semi-automatic doublechamber machine of our CleanDesign generation. It appeals by its clear forms and functions. All surfaces are made of stainless steel. The shape of the lid prevents water pools. The machine is easy to operate, servicefriendly and designed for full wash down. Clear as glass is also the menu navigation in the IGT (“Innovate Glass Touch”) control. We manufacture the duoMAT in three sizes matching your product: with sealing bars in 450, 650 or 850 mm in length. The duoMAT is designed for evacuation and...

Open the catalog to page 2

Simple operation: The lid forms the vacuum chamber. The operator places the product on one side of the flat deck and swivels the lid so that it closes atop the product. Closing the lid triggers the auto matic vacuum packaging process. The flat deck design (shown here without filler plates), allows easier access and cleaning from all sides of the machine. hygienic high-quality stainless steel WEBOMATIC CleanDesign: enables hygienic wet cleaning flat deck-style design working area open to all sides service-friendly construction tool-less sealing bar removal, no wiring in the way food-grade...

Open the catalog to page 3

Vacuum Chamber Machines Convenient operation and servicing with an innovative control and the WEBOMATIC CleanDesign Innovative control: The TFT screen provides a clear overview. With the glass touch slider wheel control, the operator can intuitively touch the wheel’s edge and center to select machine functions. Adjustable feet or wheels: We manufacture each of the three duoMAT models either with adjustable stainless steel feet or on wheels with brakes. The glass sensor control IGT (“Innovative Glass Touch”) allows controlling the machine via a touch sensitive slider wheel. The graphic TFT...

Open the catalog to page 4

Tidy: Even the lid‘s interior has been designed in the best order and is clearly arranged. The CleanDesign concept is realized here, too. Convenient servicing: The sealing bars inside the lid can be released tool-less with one hand movement. Re-assembly is just as easy. CleanDesign: All surfaces are made of stainless steel. The machine can be fully washed down. When the lid is in cleaning position, the positively controlled vacuum valves are hermetically closed. MAP nozzles: Optional equipment for packaging under modified atmosphere (protective gas) is also available. nterval vacuum: gentle...

Open the catalog to page 5

Vacuum Chamber Machines Technical data Semi-automatic double chamber machine duoMAT duoMAT 450 Width x depth: Height upper edge of the table: Height upper edge of the open lid: Chamber inside dimensions: Max. product size: Sealing bar length: Arrangement of the sealing bars: standard: optionally against surcharge: Pump size: standard: optionally against surcharge: Technical changes reserved. All WEBOMATIC machines comply with the valid European regulations according to CE, EMC, EAC. 1.375 x 850 mm 880 mm 1.335 mm 450 x 500 x 180 mm (W x D x H) 450 x 500 x 130 mm or 350 x 500 x 180 mm (L x W...

Open the catalog to page 6

duoMAT 850 Standard equipment Control IGT-premium with the following features hi-resolution colour screen 4.3” (appx. 94 x 54 mm) touch-sensitive slider wheel control vacuum processes: best-vac, ultimate value, time select; interval vacuum absolute measuring vacuum sensor for vacuum, MAP, soft-air Positively controlled vacuum valves with cleaning mode Filler plates: 8 pcs. (4 pcs. per side) 2.135 x 980 mm 880 mm 1.540 mm 850 x 645 x 200 mm (W x D x H) 850 x 645 x 150 mm or 750 x 645 x 200 mm (L x W x H). Due to the movement radius of the lid the max. product size depends on the product...

Open the catalog to page 7

Packaging is our passion We have been developing vacuum packaging machines. For 55 years. High-quality technology from Germany WEBOMATIC machines have proven best practice in almost all areas of vacuum packaging – be it perishable food, sterile cosmetic and medical products or sensitive industrial products. More than 100,000 sold machines prove our excellence. Vacuum Chamber Machines Tray Packaging Machines Shrinking and drying Thermoforming Machines Components Maschinenfabrik GmbH Hansastr. 119 D-44866 Bochum Telephone +49 (0) 2327-3099-0 Telefax +49 (0) 2327-3099-29 info@webomatic.de...

Open the catalog to page 8All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages