Catalog excerpts

Traysealers TL 300 Compact Form, Efficient Performance High Quality aus Deutschland made in Germany

Open the catalog to page 1

Semi-automatic Traysealer Small footprint but powerful Reliable capacity, simple operation, solid stainless steel construction and an exceptional hygienic WEBOMATIC CleanDesign are all With its compact dimensions, ourTL300 requires very little floor space and can be placed in the most restricted operating areas. In addition, all of the machine's key components are easily accessible from the front-side of the machine and die sets and film are well pro- tected behind the machine's tiltable hood. Our solid TL300 is the ideal tray packaging solution for operations with a need for econo- mical...

Open the catalog to page 2

Simply (and) perfectly packed Our semi-automatic traysealer is comfortably controlled via the practical full-color touch- screen with its clear and easily understandable menu navigation. Even untrained personnel can operate the intuitive control panel by simply adjusting sealing time, temperature, gas flush and vacuum degree forali packaging configura- tions. Once the product program is entered, the operator simply chooses the desired program, loads the filled trays, closes the vacuum chamber and the remaining processes are fully automated! From the vacuum process to gas flushing and...

Open the catalog to page 4

Highly versatile packaging Do you prefer round, square, colored or transparent trays? Foam, cardboard, paper, or aluminium? Choose from reclosable film or a Our entry level TL300 tray sealer offers an enormous range of packaging options. The extra wide sealing area can accommodate tray Designed for modified atmosphere packaging and/or conventional tray sealing, theTL300 is engineered to handle a wide variety of food packaging applications including tray lidding only or those requiring MAP. OPTIONAL: For using pre-printed top film the TL 300 can be equipped with an optional print mark...

Open the catalog to page 5

Semi-automatic Traysealer Technical data: tray materials: PR PS, A-PET, C-PET, EPS, paper, cardboard, aluminium max. tray dimensions for various tray configurations: Further sealing die sets and forms upon request. Sealing die sets each complete with contour-cutting (outside-cut). control system: touch screen: production capacity: machine dimensions: working height: film transport: film reel diameter: connected load: Mitsubishi full-color touch screen, high resolution up to 7 cycles/min., depending on equipment and product approx. 995 x 795 x 1,600 mm (wxdxh, closed) approx. 375 kg...

Open the catalog to page 6All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

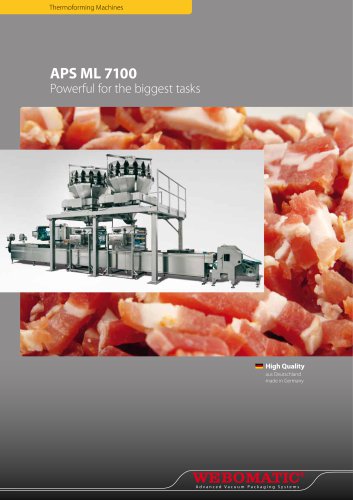

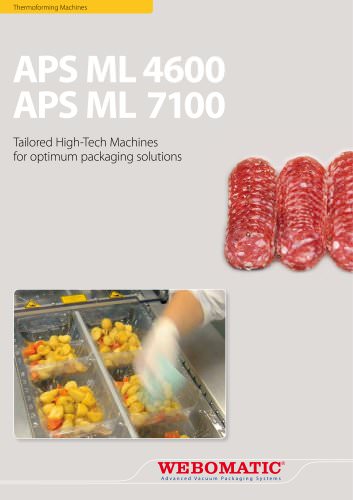

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages