Catalog excerpts

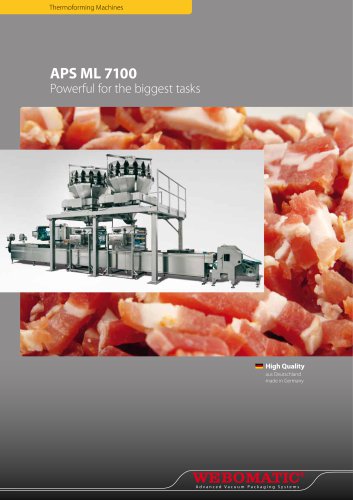

Thermoforming Machines Powerful for the biggest tasks Advanced Vacuum Packaging Systems

Open the catalog to page 1

Thermoforming Machines Reliable in the packaging process This thermoforming machine is our solution for your heaviest packaging Our thermoforming machine APS ML 7100 Our best practice APS ML 7100 is capable was built for heavy-duty, industrial-sized of mastering a 3-shift operation throughout demands. With its solid stainless steel the whole year. It ensures process stability frame construction, this high-performance and offers the optimum for maximum system will stand up even in the harshest production capacities. operating conditions. In addition, this machine is adaptable for The...

Open the catalog to page 2

From automatic filling on a very grand scale – as shown in the title page – to meticulous manual loading: This machine comes without any restrictions. Large industry packs and piece goods are typical products to be packed by the APS ML 7100. Depending on the application, our industrial-friendly power packer processes all commercial film materials (flexible films, rigid films, top and bottom printed film) p to 622 mm of width, u ith a repeat index of up to 800 mm in w length, ith a draw depth up to 190 mm. w Our APS ML 7100 will perform up 20 cycles per minute (depending on equipment and...

Open the catalog to page 3

Thermoforming Machines Sound and solid basis for intelligent details Jumbo roll: Should the floor space not allow for loading of the roll in a straight line, operators may simply load from the side with a roll support at a 90° angle. The WEBOMATIC thermoformer APS ML 7100 provides a stable basis for a variety of special equipment and accessories. For instance, the jumbo roll: The machine processes rolls with a diameter of up to 1,200 mm. With the roll trolley (included in the scope of delivery) which, of course, smoothly docks to the machine, operators can move the heavy rolls safely and...

Open the catalog to page 4

Top film forming: Useful for the creation of lids for reclosable packs. Employing a roller belt that is adjustable in height prevents heavy products from sagging. To avoid machine downtime, simply place an almost used up roll to a second support and pre-load a new roll. It is also possible to unlock the left carrier and fold it to the side, so that you can change the film roll even in limited spaces. Synchronize the APS ML 7100 with automatic filling systems or scales to achieve the highest grade of automation. Use a strip punch to create special contours. This advanced cross cutting...

Open the catalog to page 5

Thermoforming Machines Technical data Thermoforming Machine APS ML 7100 General Drive Vacuum pump Packing performance Control Monitor Measurements Length Width Height Repeat length / Index Draw depth Packing materials Film width Bottom film Thermoformable and sealable flexible film Thermoformable and sealable rigid film Roll diameter Roll core diameter Top film Sealable flexible film Roll diameter Roll core diameter Forming procedures Compressed air Compressed air and vacuum Plug assist forming Top film forming Pre-heating Standard heating in forming station from top Simple preheating from...

Open the catalog to page 6

Further options MAP, optionally also oxygen (O2) Gas mixer and/or analysis device Jumbo roll support (bottom film), also in an angle of 90° Knee-free loading zone Support rolls in the loading zone Film strip rewinding Water cooling system Lifting limit via SPS Sychronisation with automatic supply system Vibrating unit Packs with peel corners are even easier to open when the underside of the peel corner is pre-cut. The slotting device was constructed as such. The travelling punch is costefficient and saves time with format changes. Parallel buildups, such as a double complete cutting punch...

Open the catalog to page 7

Packaging is our passion We have been developing vacuum packaging machines. For 55 years. High-quality technology from Germany WEBOMATIC machines have proven best practice in almost all areas of vacuum packaging – be it perishable food, sterile cosmetic and medical products or sensitive industrial products. More than 100,000 sold machines prove our excellence. Vacuum Chamber Machines Tray Packaging Machines Shrinking and drying Thermoforming Machines Components Maschinenfabrik GmbH Hansastr. 119 D-44866 Bochum Telephone +49 (0) 2327-3099-0 Telefax +49 (0) 2327-3099-29 info@webomatic.de...

Open the catalog to page 8All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

APS ML 2000 / APS ML 3300

12 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages