Catalog excerpts

Thermoforming Machines Compact High-Quality Packaging Machines for small to medium-sized enterprises Advanced Vacuum Packaging Systems

Open the catalog to page 1

Thermoforming Machines Function diagram of the thermoforming procedure: Longitudinal cutting transported forward. the bottom film is heated In the sealing area the package is put under vacuum and, if necessary, modified gases (MAP) are added. The top film is now sealed to the bottom film by heat and pressure. unwound from the roll. Advanced Vacuum Packaging Systems

Open the catalog to page 2

Strong solutions in heavily restricted operating areas and APS ML 3300 are despite their minimal requirements for operating space real high- quality solutions for the vacuum and MAP- packaging of food and non-food products. Therefore they are the ideal tool for small and medium-sized enterprises and it is possible to use flexible soft-film or rigid packages - quick Due to their solid and high-quality construction in stainless steel, the exclusive use of first-class components by well-known manufacturers, the high dynamic servo-drive and the safe control compact Thermoforming Machines APS ML...

Open the catalog to page 3

Thermoforming Machines 2000 is the ideal tool to handle big things reguiring vacuum or MAP packaging for small and medium-sized production capacities - either in workshops, laboratories, supermarkets or large kitchens: The compact thermoforming machine does not need much space due to its front-sided construction and can be located just Depending on the product and the client's flexible film material, but also semi-rigid film material with the following widths: 280, 300, 320, 360 or 420 mm in three repeat lengths (200, 240 or 280 mm). For each basic model it is possible to choose between ten...

Open the catalog to page 4

The high-capacity APS ML 2000 is able to realize up to 10 cycles/min. depending on the pump size and the desired vacuum value correspon- ding to a capacity of up to 100 packages per minute (with die set 5.2). In order to obtain an optimum design of the packaging either pre-printed film material can be used which will exactly be positioned onto the package via the print mark control system. In addition, it is possible to realize completely free designs of packaging forms by using semi-rigid film material. Also the name of the company, the company's logo, date or number of the charge can be...

Open the catalog to page 5

Thermoforming Machines Botton film pre-unwinding-system with integrated film brake With its compact total length of only 3,5 m, the APS ML 3300 can also be located almost everywhere. Regardless, whether the professio- nally packaging of easily perishable food, sterile cosmetic or medical articles or high-sensible industrial products is concerned:The flexible thermoforming machine is able to realize high- guality vacuum and MAP packages on most restricted areas - guick and in an economical The high-capacity model convinces with a remarkable packaging capacity of up to 10 cycles per minute...

Open the catalog to page 6

Versatile cutting possibilities: Punches, guillotine or zigzag Professional packaging design by means of pre-printed top film, coder and/or labelling systems, cutting for the cross cutting as well as rotative or sgueezing knives for longitudinal cutting. For processing special film materials, such as PS or PP, a preheating system from beneath, sandwich pre-heating as well as an additional plug-assist forming system are available as options. For each basic model it is possible to choose between 12 different plug-in standard die sets, enabling a guick change of the machine within a few...

Open the catalog to page 7

Thermoforming Machines Thermoforming Machine Technical data: Technical data: Mitsubishi servo-drive, high-dynamic, electronically controlled PLC Mitsubishi FX with optional remote diagnosis approx. 36 l/cycle, max. humidity 7g/m3, pressure 7 bar min. cooling water: vacuum pump: film transport: approx. 60 l/h, pressure 3 bar, entry temperature max. 15 °C Packing material and capacity: bottom film: packing capacity: thermoformable and sealable flexible and semi-rigid film, e.g. PA/PE, A-PET, PVC roll core diameter: 76 mm/3" sealable flexible film, e.g. PA/PE, Tyvec roll core diameter: 76...

Open the catalog to page 8

Thermofornning Machine Technical data: Technical data: Mitsubishi servo-drive, high-dynamic, electronically controlled cooling water: vacuum pump: film transport: PLC Mitsubishi FX with optional remote diagnosis approx. 60 l/cycle, max. humidity 7g/m3, pressure 7 bar min. approx. 60 l/h, pressure 3 bar, entry temperature max. 15 °C Packing material and capacity: bottom film: thermoformable and sealable flexible and rigid film, e.g. PA/PE, A-PET, PS, PVC, roll core diameter: 76 mm/3" sealable flexible film, e.g. PA/PE,Tyvec roll core diameter: 76 mm/3" depending on eguipment and product, up...

Open the catalog to page 9

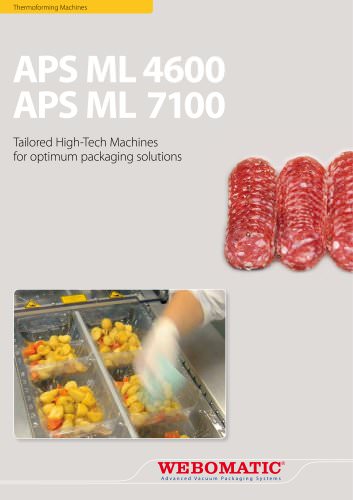

Thermoforming Machines Tailored thermoformed packages to suit each customers requirement APS ML 2000 PA/PE, Tyvec films ● ●● — — up to 400 µm APS ML 3300 APS ML 4600* APS ML 7100* ● ● ● ●●●● ●●●● ●●●● up to 600 µm up to 800 µm up to 1.200 µm standard heating in forming station from top ● ● ● ● simple pre-heating from beneath — ● ● ● sandwich pre-heating — ● ● ● 1x 2x 3x plug assist forming — ● ● ● pre-printed top film ● ● ● ● stamp-coder — ● ● ● — — ● — ● ● ● ● standard guillotine cut ● ● ● ● zigzag cut ● ● ● ● cutting punch for round corners ● ● ● ● perforation cut — ● ● ● stripe punch — —...

Open the catalog to page 10

vacuum packaging machines. High-quality technique from Germany WEBOMATIC machines have successfully proven their values worldwide in almost all areas of packaging. Regardless, if the optimum vacuum packaging of easily perishable food, sterile cosmetic and medical eguipment or high sensible industrial products is concerned. Convincing product features • first-class processing • high-guality materials and components • easy operation Vacuum packaging machines for workshops and industry, for the food and non-food area From the WEBOMATIC location in Bochum everything is realized from the...

Open the catalog to page 11All WEBOMATIC catalogs and technical brochures

-

SHRINKING AND DRYING UNITS

5 Pages

-

THERMOFORMING MACHINES

37 Pages

-

VACUUMPACKAGING MACHINES

35 Pages

-

TRAY SEALER

33 Pages

-

TL 250

1 Pages

-

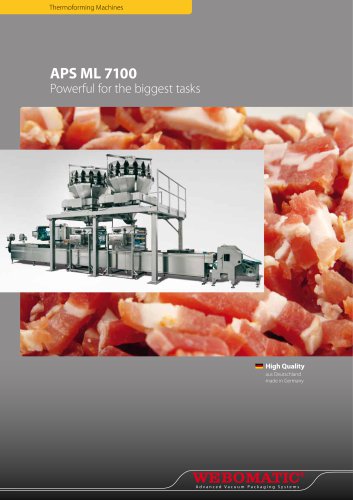

APS ML 7100_2013

8 Pages

-

ML-C 2600/3600/5600

13 Pages

-

WBM 1350-II

12 Pages

-

Double Chamber Machines

4 Pages

-

duoMAT 450/650/850

8 Pages

-

Shrinking Drying Transporting

12 Pages

-

ST 40/60-II ST 60/80-II

4 Pages

-

TL 500/TL 500-duo/TL 1100

12 Pages

-

Brochure TL 300

6 Pages

-

Brochure Table machines

4 Pages

Archived catalogs

-

APS ML 7100_2008

12 Pages