Website:

Waukesha Cherry-Burrell

Website:

Waukesha Cherry-Burrell

Group: SPX FLOW

Catalog excerpts

Users of Waukesha Cherry-Burrell® PD pumps benefit from decades of continuing product improvement. Steady advances in design, metallurgy and fabrication techniques have yielded progressively higher levels of performance and service life. THE UNIVERSAL® 2 SERIES of pumps is the latest expression of this tradition. They combine 3-way mounting versatility introduced by the Universal 1 with new features that extend pump life and improve sanitary performance. Pump is available in CIPable configurations. SPX FLOW, Inc. (NYSE:FLOW) is a leading manufacturer of innovative flow technologies, many of...

Open the catalog to page 2

Installation Features • Bidirectional flow. Rotors, locked with belleville washers and torqued nuts, rotate securely in either direction. No more flow direction/shaft position specifications. Typical product applications • Interchangeable installation dimensions with Universal 1 and Universal Lobe PD pumps. (Except for 320 and 324 sizes) • Versatile 3-Way mounting of gear case, including vertical alignment of ports. • pper or lower shaft position. U • Jacketed or vented cover optional. Soups, Stews. Tomato Paste • Non-galling Waukesha “88” alloy rotors standard; permits running at tighter...

Open the catalog to page 3

Time-tested Waukesha Cherry-Burrell® rotary pump; circumferential-piston operating principle T H E O RY O F O P E R AT I O N In the Waukesha Cherry-Burrell design, arc-shaped “pistons” (rotor wings) travel in annular-shaped cylinders machined in the pump body; the resulting long sealing path reduces slippage and produces a smooth flow of product without destructive pulses or pressure peaks and without valves or complex parts. Rotors, made of Waukesha “88” alloy, can be run with close clearance to the 316L stainless steel fluid head, without galling or seizing should inadvertent pressure...

Open the catalog to page 4

*For capacities above 830 to 935 GPM (189 to 212 m3/hr), see bulletin FH-1725 on 420/520 UHC (ECP Rotors). **Contact application engineering for higher pressure or higher temperature applications.

Open the catalog to page 5

Performance and Long Life Through Engineering. Th e Wa u ke s h a C h e r r y - B u r r e l l U n i v e r s a l 2 S e r i e s g i v e s y o u . . . High pressure capability, up to 500 psi/34.5 bar, for more demanding jobs. Longer service life, resulting from fresh engineering approach and high capacity components. The right seal, for every application, plus interchangeability when needed. Metal rotor: Waukesha “88” non-galling alloy, for close running clearance. Design conforms, to 3-A, USDA, EHEDG Type EL Class 1, SO 9001:2000 and CE standards*. timing gears mounting gear *Not all versions...

Open the catalog to page 6

Double Concentric Field Interchangeable Mechanical Seal* Used with flushing fluid to cool, lubricate, flush away residue. Best arrangement for severe service. Single Mechanical Seal* Carbon-to-ceramic faces standard. Alternate materials available for abrasive service. Elastomer choices for “O” rings: • Buna-N • Fluoroelastomer (FKM) • EPDM • Silicone • Perfluoroelastomer (FFKM) • PTFE Encapsulated *Mechanical seal material options: • Carbon • Ceramic • Silicon Carbide • Tungsten Carbide Front bearing fixed; rear

Open the catalog to page 7

Standard & Options Ports S t a n d a r d S a n i t a r y C l a m p Ty p e Is available in a variety of Bevel Seat styles including S-Line, I-Line Male NPT and 150 lb. flanges optional on Models 006 through 220 size. 150 lb. flanges standard on Model 320. Contact factory for available rectangular flange inlets. Twin Wing Single Wing on fluids with discrete most applications. particles, such as diced tomato products. Rotor Clearance Standard for most applications up to 180°F (82°C). Hot clearance rotors option for applications up to 300°F (149°C). Other special clearances available. Buna-N...

Open the catalog to page 8

Shaft Position Standard left hand shaft position shown (right hand optional) Optional Side Mount Gear Case for vertical fluid entry and free draining of body Flat plate, epoxy painted, with adjustable feet, SS coupling guard, and Lovejoy or Woods coupling standard. Options: • 304 SS unpolished plate base with adjustable feet. • Portable base with rubber wheels. • SS tubular bases. WCB ISR Integral Speed Reducer Sizes 49, 79 and 239. Direct connected gear motors. Mechanical and Electronic Variable Speed Drives. Hydraulic Motor Drives. Close coupled Tru-Fit® pump mounted on Epoxy-painted open...

Open the catalog to page 9

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings on Models 006 through 220. Dimension "2X" applies for 6" 150 lb. RF Flange on Model 320. Consult factory for available rectangular flange inlets. NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Open the catalog to page 10

UNIVERSAL 2 MODELS - RECTANGULAR FLANGE NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed. *Optional Pedestal sizes are available please contact factory for more details. UNIVERSAL 2 MODELS - TRU-FIT® NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Open the catalog to page 11

When it is time to repair ... SPX FLOW offers the following options – you pick the one that meets your needs. Fa c to r y Reman u f ac t u ri n g Progra m • No need to return your pump until you • Return your pump for extensive factory • Local distributors with factory trained and receive your new replacement pump. certified service technicians. • Substantial savings over new pump. • Cost effective options to match your • Quick local response. • All remanufactured pumps must pass a performance/budget needs. 25 point inspection process and undergo • Your pump body may be remachined up to 6 •...

Open the catalog to page 12All Waukesha Cherry-Burrell catalogs and technical brochures

-

Universal TS Series

8 Pages

-

Manual Valves

12 Pages

-

C-Series

8 Pages

-

Universal® 1 Series

12 Pages

-

Universal 1 PD Pump Seals

1 Pages

-

Universal 2 Pump Seal

1 Pages

-

Universal 3 Pump Seal

1 Pages

-

WCB Control Tops

2 Pages

-

Scraped Surface Heat Exchangers

12 Pages

-

Filters And Strainers

4 Pages

-

Universal 3 Series

12 Pages

-

Votator® I

12 Pages

-

CR Mixer

2 Pages

-

DTL Blender

26 Pages

-

Colloid Mill

2 Pages

-

Shear Pump

2 Pages

-

WFI Centrifugal Pump

2 Pages

-

Universal 420/520 High Capacity

12 Pages

-

Postive Displacement Pumps

12 Pages

-

Shear Pumps

2 Pages

-

Colloid Mills

2 Pages

-

Rising Stem Valve Sensor

1 Pages

-

Butterfly Valves 200 Series

4 Pages

-

Manual Ball Valve Key

4 Pages

-

Over-Pressure Valves

12 Pages

-

W75 Series PMO Mix Proof Valves

12 Pages

-

W68 Series Control Valves

16 Pages

-

FH-1723 - Universal II Series

12 Pages

-

FH-1702 - 200 Centrifugal Pump

12 Pages

-

BPE Fittings

32 Pages

-

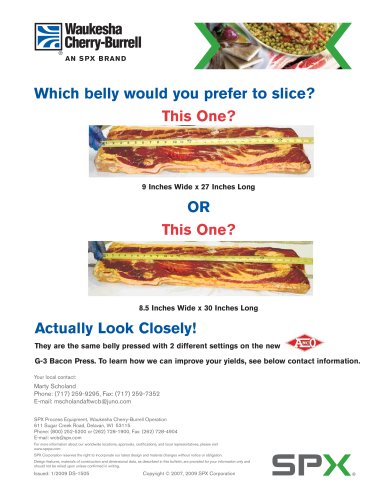

We Know Bacon - Flyer

1 Pages

-

Self-Priming Pump Flyer

2 Pages

-

Close Coupled Pump Drive

1 Pages

-

Sanitary Fittings & Clamps

68 Pages

-

Filters/Strainers

4 Pages

Archived catalogs

-

CR Mixer

2 Pages

-

Mix Proof Valve Key

8 Pages

-

420/520 UHC (EHP)

12 Pages

-

Pump Remanufacturing Program

8 Pages

-

Universal Lobe Product Line

12 Pages

-

Pumps “C” Series

4 Pages

-

Manual Valves (WCB-1858)

12 Pages

-

Single Seat Valve Key

8 Pages

-

W72 RS Mix Proof Valves

4 Pages

-

W45 Check Valves

2 Pages