Website:

Waukesha Cherry-Burrell

Website:

Waukesha Cherry-Burrell

Group: SPX FLOW

Catalog excerpts

611 Sugar Creek Road Delavan, WI 53115 USA Tel: (800) 252-5200 or (262) 728-1900 Fax: (800) 252-5012 or (262) 728-4904 E-mail: wcb@spx.com Web site: www.spx.com Information contained in this manual is subject to change without notice and does not represent a commitment on the part of SPX. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of SPX. Copyright © 2007 All Rights Reserved. Issued Date: December 22, 2000 Revised Date: February...

Open the catalog to page 2

Waukesha Cherry-Burrell Waukesha Cherry-Burrell Warranty Seller warrants its products to be free from defect in materials and workmanship for a period of one (1) year from the date of shipment. This warranty shall not apply to products which require repair or replacement due to normal wear and tear or to products which are subjected to accident, misuse or improper maintenance. This warranty extends only to the original Buyer. Products manufactured by others but furnished by Seller are exempted from this warranty and are limited to the original manufacturer’s warranty. Seller’s sole...

Open the catalog to page 4

Waukesha Cherry-Burrell Safety READ AND UNDERSTAND THIS MANUAL PRIOR TO INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT Waukesha Cherry-Burrell recommends users of our equipment and designs follow the latest Industrial Safety Standards. At a minimum, these should include the industrial safety requirements established by: 1. Occupational Safety and Health Administration (OSHA), Title 29 of the CFR Section 1910.212- General Requirements for all Machines National Fire Protection Association, ANSI/NFPA 79 ANSI/NFPA 79- Electrical Standards for Industrial Machinery National Electrical Code,...

Open the catalog to page 5

Waukesha Cherry-Burrell Introduction Description The DTL Blender is designed to introduce a dry material to a liquid and through a mechanical action provide a blended end product for a process. The DTL Blender has two sections, the dry material section and the liquid material section. The DTL Blender model WP3218MD is mounted on a base plate. The blender is driven by belts located under the base plate. These belts are driven by the drive motor mounted next to the blender assembly. A electrically controlled butterfly valve and control panel are standard equipment on model WP3218MD. The...

Open the catalog to page 6

Waukesha Cherry-Burrell Installation Unpacking The model WP3218MD DTL Blender is packed in two separate shipping containers, the hopper is in one crate, the Blender and its components are packaged in another crate. The blender and drive motor are mounted to the base plate which is secured to a wood pallet. For best performance locate DTL Blender unit within 3 feet of the liquid source and in a position where the supply piping will be short and direct with a minimum number of elbows and fittings. When installing the unit consider accessibility for future cleaning and inspection. The...

Open the catalog to page 7

Waukesha Cherry-Burrell Maintenance The DTL Blenders are relatively maintenance free, requiring normal cleaning and inspection to ensure optimum performance. Cleaning DANGER: ALWAYS turn off the electrical power supply and Lock Out, using a locking device for which only the person doing the work has the key, before performing service or maintenance. 10. Rinse with hot water to facilitate quick drying and to eliminate water spotting. WARNING: Hydrochloric acid, even with inhibitors added, is not recommended for cleaning stainless. (Inhibitors are specific compounds that are added to cleaning...

Open the catalog to page 8

Waukesha Cherry-Burrell DTL Blender Disassembly It is recommended that periodic inspection of all parts of the DTL Blender be made to prevent malfunctions caused by worn or broken parts. At this point, disassembly will vary, depending on the type of seal the blender has refer to the following procedures specific to your seal arrangement. The following disassembly procedures cover the WP2116MD and WP3218MD models. Portions of the disassembly are identical for all models, but where differences occur the procedure for each model will be indicated. External Balanced Type D, F. Dg Seals: 1....

Open the catalog to page 9

Waukesha Cherry-Burrell Deflector and Stub Shaft Removal 1. Loosen the two set screws and remove the drive collar. The remaining carbon seal, seal O-ring, cup and the follower may now be removed from the shaft. When removing the drive motor from the base plate, place a suitable block beneath the motor and turn the adjustable legs until the motor rests firmly on the block. To remove deflector, lift straight off. Remove the four nuts, bolts, and lock washers securing the motor to the base plate. With the motor resting on the blocks, lift the base plate off of the motor, leaving the stub shaft...

Open the catalog to page 10

Waukesha Cherry-Burrell Install the adjusting legs into the base. Install the bearing housing on top of the base plate. Install the ring adapter onto the base plate, place the base plate on top of the motor and install the motor. Tip the blender on end and install the adapter ring. Install the blender pulley key and bushing. Place the motor mounting screws (4) in position. Attach the nuts and washers, but do not tighten them securely at this time. The motor must remain loose enough to allow alignment of the motor stub shaft in the backplate. Place the pulley in position and be certain to...

Open the catalog to page 11

Waukesha Cherry-Burrell Disassembly of the Butterfly Valve Setting the Drive Collar In the event that repair or replacement becomes necessary, the following procedures are suggested: Blenders With D, F. Or DG Seals Install the deflector on the shaft. When the drive collar has been removed or the carbon seal has been replaced, the drive collar must be positioned on the shaft by one of two following methods: Drain and flush the piping surrounding the valve. To remove handle, remove the socket head capscrew found at the top of the valve handle with the proper sized allen wrench. Remove the...

Open the catalog to page 12

Waukesha Cherry-Burrell Blenders With E Seals 1. Install the backplate, gasket, and casing. 2. Install and tighten casing clamp. At a location behind the backplate scribe a mark on the shaft. See Figure C. Remove casing clamp, casing, and backplate. Slide the follower, one carbon seal, one seal O-ring, one seal cup, and drive collar onto the shaft. Locate drive collar in relation to the scribe mark as shown in Figure C and secure to the shaft with the set screws. NOTE: Drive collar location is critical. 6. Install the seal spring, seal cup, seal O-ring and carbon onto the shaft. Be sure the...

Open the catalog to page 13All Waukesha Cherry-Burrell catalogs and technical brochures

-

Universal TS Series

8 Pages

-

Manual Valves

12 Pages

-

C-Series

8 Pages

-

Universal® 2 Series

12 Pages

-

Universal® 1 Series

12 Pages

-

Universal 1 PD Pump Seals

1 Pages

-

Universal 2 Pump Seal

1 Pages

-

Universal 3 Pump Seal

1 Pages

-

WCB Control Tops

2 Pages

-

Scraped Surface Heat Exchangers

12 Pages

-

Filters And Strainers

4 Pages

-

Universal 3 Series

12 Pages

-

Votator® I

12 Pages

-

CR Mixer

2 Pages

-

Colloid Mill

2 Pages

-

Shear Pump

2 Pages

-

WFI Centrifugal Pump

2 Pages

-

Universal 420/520 High Capacity

12 Pages

-

Postive Displacement Pumps

12 Pages

-

Shear Pumps

2 Pages

-

Colloid Mills

2 Pages

-

Rising Stem Valve Sensor

1 Pages

-

Butterfly Valves 200 Series

4 Pages

-

Manual Ball Valve Key

4 Pages

-

Over-Pressure Valves

12 Pages

-

W75 Series PMO Mix Proof Valves

12 Pages

-

W68 Series Control Valves

16 Pages

-

FH-1723 - Universal II Series

12 Pages

-

FH-1702 - 200 Centrifugal Pump

12 Pages

-

BPE Fittings

32 Pages

-

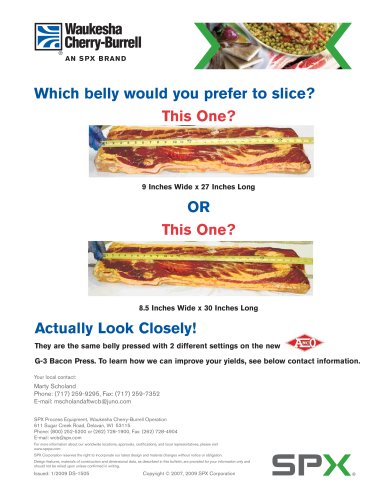

We Know Bacon - Flyer

1 Pages

-

Self-Priming Pump Flyer

2 Pages

-

Close Coupled Pump Drive

1 Pages

-

Sanitary Fittings & Clamps

68 Pages

-

Filters/Strainers

4 Pages

Archived catalogs

-

CR Mixer

2 Pages

-

Mix Proof Valve Key

8 Pages

-

420/520 UHC (EHP)

12 Pages

-

Pump Remanufacturing Program

8 Pages

-

Universal Lobe Product Line

12 Pages

-

Pumps “C” Series

4 Pages

-

Manual Valves (WCB-1858)

12 Pages

-

Single Seat Valve Key

8 Pages

-

W72 RS Mix Proof Valves

4 Pages

-

W45 Check Valves

2 Pages