Catalog excerpts

Lubrication Filtration climate control process control sealing & shielding ENGINEERING YOUR SUCCESS.

Open the catalog to page 1

Lubrication Filtration Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 2

Lubrication Filtration Top-Load Filters A permanent assembly houses Racor top-load oil filter. The top-load filters meet the requirements of today's oil-controlled, high pressure fuel injection systems. Racor media meets the variable geometry and variable nozzle turbocharger requirements. An uncompromising, high level of fluid cleanliness is needed to achieve operating efficiency and reach service cartridge oil filters are crushable, replace. Filter service is from the top of the module and skin contact is minimal due to the unique screw top permanent assembly is customized with a patented...

Open the catalog to page 3

Lubrication Filtration Environmental Responsibility Designing products that help protect at Racor Division. Thousands of engineering hours are invested to meet OEM specifications with environmentally-friendly products. Racor top-load oil filters are metal free and crushable, taking less disposal space and incinerable, leaving only a Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 4

Lubrication Filtration Top-loading filter friendly - cleaner, easier, quicker than servicing under-engine mounted High performance, high efficiency engineered filter media. incinerable element. integral into the system. The filter element and screw top design that minimizes skin contact during service. System patents ensure that equipment owners receive genuine OEM replacement filters. Patented center tube filter design includes chamber, contaminants aluminum housing. from engine mounting base. Auto drain Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 5

Lubrication Filtration The Racor LFS 300 Series Retrofit Kits allow the conversion from a standard metal spin-on disposable canister to a premium cartridge oil filter. These revolutionary systems feature a crushable, burnable replacement cartridge element that offers increased The Racor 300 Series Lubrication Filtration Systems are unique in their configuration. They feature a spin- on die-cast aluminum canister that mounts directly to the engine in place of the existing spin-on filter. The engineered design of the Racor cellulose filter element provides for an environmentally clean and...

Open the catalog to page 6

Lubrication Filtration Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 7

Lubrication Filtration Replacement Parts Part Number Description Replacement Elements Additional Parts (not shown) Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 8

Lubrication Filtration The Racor Bypass Oil Series removes dirt, varnish, ash, tar, soot and other moisture that full-flow filters cannot remove from your engine's oil. The system also removes condensed water, which forms component- damaging acids if left in the oil. The Racor Bypass Oil Series removes contaminants down to one micron, which minimizes wear and extends engine component life. The polishing effect of the Racor Bypass Oil Series system will allow the engine oil service intervals to be extended. By reducing the disposal of waste oil, the system also contributes to preserving The...

Open the catalog to page 9

Lubrication Filtration • For accurate engine flow rates, consult your engine or equipment manual, manufacturer's agent or a Racor distributor. •The only accredited way to extend your oil change interval is through a formal lube analysis program. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 10

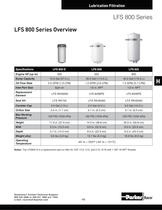

Lubrication Filtration Notes:The LFS802-S is a replacement spin-on filter for CAT: C10, C12, and C15, 3176 with 1 3/8"-16 NPT threads. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 11

Lubrication Filtration Mounting Information Back View Top View Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 12

Lubrication Filtration LFS 801 Mounting Information 5.4 in. (13.7 cm) 3.8 in. (9.7 cm) ) 6.0 in. (15.2 cm) 1.5 in. (3.8 cm) 2x 1/4-18 NPT 7.6 in. (19.3 cm) 5.7 in. (14.5 cm) 1/8-27 Questions? Contact Technical Support: 800 344 3286 or 209 521 7860 ext. 7555 e-mail: racortech@parker.com H H11

Open the catalog to page 13

Lubrication Filtration Mounting Information Back View Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 14

Lubrication Filtration LFS 802-S Spin-on Filter Mounting Information 5.4 in. (13.7 cm) (1-3/8-16 UN-2B) H 11.2 in. (28.4 cm) Questions? Contact Technical Support: 800 344 3286 or 209 521 7860 ext. 7555 e-mail: racortech@parker.com H13

Open the catalog to page 15

Lubrication Filtration Mounting Information Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 16

Lubrication Filtration Bypass Filter Test Data Disposable Filter Racor Bypass (after) Racor Bypass Filter Partical Size (micron) At 1,549 miles on the oil,an oil sample is taken, then the bypass filter is change interval. Sample taken bypass filter 'ISO code after 4,319 miles with a Racor Bypass filter. After 8,674 miles with a cleaner than with a Base Sample Standard Drain Interval Extended Drain Interval Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 17

Lubrication Filtration Customer Interface Drawing CUSTOMER INTERFACE DRAWING Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 18

Lubrication Filtration Customer Interface Drawing —S TAMP DATE CODE NOTES: UNLESS OTHERWISE SPECIFIED- HEAD: BLACK ANODI ZED ALUHIMUM. CANISTER: WHITE POWDER COATED STEEL. BRACKET: PLATED STEEL. FASTENERS: PLATED STEEL. CUSTOMER INTERFACE DRAWING THIS PRINT SUPERSEDES ANY EARLIER DATE, DESTROY SAME MADE PUBLIC CE COPIED UNLESS FILTER ASSEMBLY. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 19

Lubrication Filtration Customer Interface Drawing NOTES : UNLESS OTHERWISE SPECIFIED- HEAD: BLACK ANODI ZED ALUMINUM CANISTER: WHITE POWDER COATED STEEL. BRACKET: PLATED STEEL FASTENERS: PLATED STEEL. ELEMENT: UTILIZE 46595 CARTRIDGE WITH END CAPS. CUSTOMER INTERFACE DRAW ING REVISE ONLY ON ProE SYSTEM THIS PRINT SUPERSEDES ANÏ EARLIER DATE: DESTROY SAME FILTER ASSEMBLY. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 20All Watts Fluid Air catalogs and technical brochures

-

QUBE Modular FRLs

56 Pages

-

QIX Modular FRLs

20 Pages

-

Injection Lubricators

20 Pages

-

Airline Accessories

144 Pages

-

High Pressure Filters

28 Pages

-

Section: M Hydraulic Filtration

16 Pages

-

Section: G Crankcase Filtration

28 Pages

-

Section: D Alternative Fuel

16 Pages

-

Section: F Air Filtration

130 Pages

-

Compressed Air Dryers

16 Pages

-

Stainless Steel FRLs

25 Pages

-

Miniature FRL Series

28 Pages

-

Dryer Products

32 Pages

Archived catalogs

-

Air Preparation Units

90 Pages

-

Airline Accessories

225 Pages

-

Injection Lubricators

17 Pages

-

Miniature FRL Series

44 Pages

-

Stainless Steel FRLs

25 Pages