Website:

Watts Fluid Air

Website:

Watts Fluid Air

Group: Parker

Catalog excerpts

Crankcase Filtration climate control process control sealing & shielding ENGINEERING YOUR SUCCESS.

Open the catalog to page 1

Crankcase Filtration Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 2

Crankcase Filtration Open Crankcase CV systems include a crankcase pressure regulator with Integral bypass valve that minimizes variation In crankcase pressure. Excessive variation In crankcase pressure can damage seals, cause loss of oil, and other problems. right-hand inlet. Stainless steel latches for tool-less filter change. Replaceable high- performance filter with depth-loading, micro-glass fiber coalescing media. Extended filter service Interval from the Vaporbloc™ element. Steel housing with epoxy powder coating. - Drain check valve allows crankcase. This eliminates frequent...

Open the catalog to page 3

Crankcase Filtration 'Units can be manifolded to handle higher flow rates. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 4

Crankcase Filtration ' Dimension "G" is the minimum filter removal clearance - allow more room if possible for ease of service. 2 Dimension "J" is not applicable on CV4501 assemblies because there are only two (2) mounting holes. All other units have four (4) mounting holes. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 5

(The diagram below illustrates how part numbers are constructed) Oil Return Back to Engine Flow of Crankcase Emissions / \ System Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 6

Crankcase Filtration CV Hose and Fitting Kits CCV55024 (1) %" fitting, (1)1" fitting, (1) %" ID x 4 foot long hose, (1) 1 " ID x 4 foot long hose, (4) clamps and (4) ties CCV55025 (2) 1 " fittings, (1) 1 " ID x 8 foot long hose, (4) clamps and (4) ties 4 foot long hose, (4) clamps and (4) ties CCV55038 (1) %" fitting, (1)1" fitting, (1) %" ID x 6 foot long hose, (1) %" Tee fit- ting, (1) 1 " ID x 4 foot long hose, (8) clamps and (8) ties Questions? Contact Technical Support: Hose and fitting kits include inlet and outlet fittings and enough hose assembly. CV assemblies require special...

Open the catalog to page 7

Crankcase Filtration Electronic Remote Filter Gauge designed to inform the user that the filter being monitored has become restricted. During normal vehicle operation, the green light stays illuminated indicating the filter is performing properly. The red light iluminates when the filter becomes restricted and stays on until the engine is shut down. The light box is reset when the engine is shut down and the red light will not illuminate until filter restriction is again seen Product Features: Constant monitoring of filter condition while engine is on 12Vdc operating supply voltage...

Open the catalog to page 8

Crankcase Filtration Hose Barbs Part Number: offers 60% additional media. applications where extra capacity is desired and immediate engine allows for increased efficiency and longer service intervals. Kit includes element, wear spacer, o-rings, and Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 9

Crankcase Filtration Questions? Contact Technical Support e-mail: racortech@parker.com

Open the catalog to page 10

Crankcase Filtration Closed Crankcase CCV systems integrate three distinct First is to provide coalescing and separation of oil mist particles, soot, and liquid volatiles created during combustion process. CCV systems employ a depth loading media that has a very low pressure drop through the filter, but increases the ability to coalesce particles out of the blow-by gas. With this, we are able to achieve very high efficiencies and maintain crankcase pressure between -4 to +4 inches of water on closed systems. Second is to provide a sump chamber and check valve which returns coalesced liquid...

Open the catalog to page 11

Crankcase Filtration Market Challenges and Overview Releasing Pollutants Through Unfiltered Breathers legislation to control crankcase emissions have increased significantly. To further reduce the total emissions of engines, in some applications it is becoming necessary to close the crankcase breather system, routing these gases into the air intake system. Crankcase blow-by is produced when combustion gases under high pressure are blown passed the piston rings into the crankcase. As these blow-by gases pass though the crankcase, they become contaminated. Racor's Crankcase Ventilation System...

Open the catalog to page 12

Crankcase Filtration Unique crankcase pressure regulator with integral bypass valve minimizes variation in crankcase pressure. Excessive variation in crankcase pressure can damage seals, cause loss of oil, and other problems Pop-up style indicator alerts of bypass condition and need for filter change right-hand inlet. Available with Stainless steel latches Replaceable high- performance filter — with depth-loading, micro-glass fiber coalescing media. Extended filter service Vaporbloc™ element. Steel housing with epoxy powder coating Drain check valve allows collected oil to return to...

Open the catalog to page 13

Crankcase Filtration auto draining. Note: Not all configurations are standard. See CCV Assemblies for a complete description of all assemblies offered. Oil Return Back to Engine Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 14

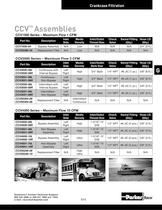

Crankcase Filtration CCV™ Assemblies CCV1500 Series - Maximum Flow 1 CFM CCV3500 Series - Maximum Flow 3 CFM CCV4500 Series - Maximum Flow 10 CFM Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 15

Crankcase Filtration CCV™ Assemblies CCV6000 Series - Maximum Flow 20 CFM CCV8000 Series - Maximum Flow 40 CFM CCV12000 Series - Maximum Flow 50 CFM Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 16

Crankcase Filtration Units can be manifolded to handle higher flow rates. Do not use CCV1500 in continuous duty applications. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 17

Crankcase Filtration ' Dimension "G" is the minimum filter removal clearance - allow more room if possible for ease of service. CCV1500 and CCV3500 Series filters are serviced from top. 2 Dimension "J" is not applicable on CCV1500, 3500, and 4500 assemblies because there are only two (2) mounting holes. All other units have four (4) mounting holes. Questions? Contact Technical Support: e-mail: racortech@parker.com

Open the catalog to page 18All Watts Fluid Air catalogs and technical brochures

-

QUBE Modular FRLs

56 Pages

-

QIX Modular FRLs

20 Pages

-

Injection Lubricators

20 Pages

-

Airline Accessories

144 Pages

-

High Pressure Filters

28 Pages

-

Section: M Hydraulic Filtration

16 Pages

-

Section: D Alternative Fuel

16 Pages

-

Section: F Air Filtration

130 Pages

-

Compressed Air Dryers

16 Pages

-

Stainless Steel FRLs

25 Pages

-

Miniature FRL Series

28 Pages

-

Dryer Products

32 Pages

Archived catalogs

-

Air Preparation Units

90 Pages

-

Airline Accessories

225 Pages

-

Injection Lubricators

17 Pages

-

Miniature FRL Series

44 Pages

-

Stainless Steel FRLs

25 Pages