Website:

Watter

Website:

Watter

Catalog excerpts

About process water Guarantee the optimum microbiological quality of your process water Contamination of the water can lead to a loss of quality and undesirable odours and tastes, among other things, with possible consequences. In addition to cleaning, disinfection measures are also necessary. In this white paper you will find explanations and tips for clean and reliable water in your company. From microbiologists Reinoud Homan and Eva Dankers - 2024

Open the catalog to page 1

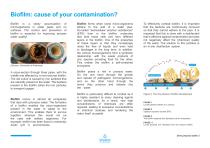

Biofilm is a sticky accumulation of microorganisms in water pipes and on surfaces. The control and prevention of biofilm is essential for improving process water quality! A cross-section through three pipes, with the middle one affected by a red-coloured biofilm. The red colour is caused by iron particles that are naturally present in the water. The bacteria present in the biofilm utilise the iron particles to transport oxygen. Biofilm occurs in almost all companies that deal with (process) water. The formation of a biofilm enables the micro-organisms present in the water to adapt to the...

Open the catalog to page 2

Bulging packaging, unpleasant odours after opening or visible mould on the product: all signs that something is wrong with the contents. Waste is a hot topic: shelf life is linked to expectations and therefore poses a potential risk to customer satisfaction. But it's hard to predict how well a product will leave the factory. Laws and regulations mean that almost every company records, manages and controls all processes to ensure the quality of the process water. In particular, the introduction of the clean-in-place process in the 1960s played an important role in automating these hygiene...

Open the catalog to page 3

Over process water 4 In-situ, the future of disinfection The applications of in-situ disinfection are at the centre of interest. With in-situ disinfection, the disinfectant is produced and applied on site. This eliminates production, transport and storage in one go. In addition, the disinfectant is ready to use and always fresh, so there is less risk of harmful residues forming. In-situ production is carried out by electrolysis of salt and water, resulting in a disinfectant with HOCl as the active ingredient. This means a very broad effectiveness and therefore significantly better results....

Open the catalog to page 4

In order to improve the regulation of disinfectants in the European Union, the Biocidal Product Registration (BPR) was established, which is managed by the European Chemicals Agency (ECHA). A disinfectant must be registered for the application for which it is used. To ensure uniformity and safety, a transition from national to European legislation is taking place. Current legislation has recognised in-situ technology for disinfection, a major step towards more sustainable forms of disinfection. There are various possible applications for Watter's in-situ technology. The legislator has...

Open the catalog to page 5

How does the Watter-system work? Customisation: Our team of scientists and technologists work together to ensure the production of clean water through the best product and service quality. Every customer receives personalised support and all findings are scientifically validated. This keeps us close to our customers' needs and increases our impact. Every day, this brings us one step closer to our vision for the future: A world without harmful chemicals. Effectiveness: The effectiveness of the agent has been proven by EN tests for a wide range of applications, including against bacteria (EN...

Open the catalog to page 6

AMERICOL COLLALL' lAdhesives & Paints since 1949 "Over the years, a biofilm had formed in our pipework. After a disinfection measure, the contamination receded, but it kept coming back. We therefore switched to an almost fully automatic disinfection system. Since then, the bacterial count has always been zero." "With the Watter system, we only dose 4 ppm hypochlorous acid all year round. Due to its enormous effectiveness, we have not detected a single germ since its introduction." "Through structural disinfection, we have optimised our production process, resulting in hardly any loss of...

Open the catalog to page 7

<f> Watte c Sustainable Disinfection E-Mail: info@watter.nl

Open the catalog to page 8