Website:

WARREN RUPP

Website:

WARREN RUPP

Group: Idex Corporation

Catalog excerpts

For Ceramic Duty . Mixing Tanks . Gravity Casting . Casting Machines . Tank Transfer . Mold Cleaning . Glaze Spray . Waste Treatment . Utility Over 40 Years Ceramic Industry Experience!

Open the catalog to page 1

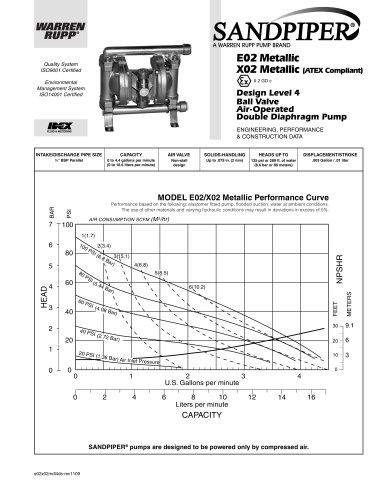

100 10(17) 20(34) 30(51) 40(68) 50(85) 60(101.9) 70(118.9) 80(135.9) 90 80 70 60 50 40 30 20 10 0 0 10 20 30 40 50 60 70 80 90 80 PSI 100 PSI 60 PSI 40 PSI 20 PSI Air Inlet Pressure 1½" PERFORMANCE CURVE Liters per minute U.S. Gallons per minute CAPACITY 0 100 150 200 250 350 AIR CONSUMPTION SCFM (M3/hr) BAR 50 300 HEAD 0 1 2 3 4 5 6 7 PSI 90(152.9) * 20(34) 40(68) 60(101.9) 80(135.9) 100(169.9) 120(203.9) 140 (237.9) 160(271.8) 180(305.8) 200(339.8) 90 80 70 60 50 40 30 20 10 0 0 20 40 60 80 100 120 140 160 180 200 220 240 260 100 PSI 80 PSI 60 PSI 40 PSI 20 PSI Air Inlet Pressure 100 3"...

Open the catalog to page 2

Process Map for Ceramic Rely on the field-proven experience ...to deliver the superior quality and performance Mixing Tanks below ground Mixing Tanks above ground Holding Tanks Tank Cars or Rail Cars Holding Tanks Ideal Pump Types for your HDF Raw Materials Raw Materials HDB HDB HDB HDF Best Dead Settling Suction Type Head Abrasives APPLICATIONS Ÿ Tank & Rail Cars Raw materials used in the manufacture of ceramic products are often delivered to the facility in slurry form. Sandpiper pumps are used to unload tank trucks and railway cars. Ÿ Holding Tanks Filtered fluids are often recirculated...

Open the catalog to page 3

Ceramic Manufacturing experience of SANDPIPER® performance needed for ceramic manufacturing Suction High Chemical Abrasives Lift Pressure Non-Metallic Resistance Other Considerations Choose a pump with high flow rates so that the time to unload the tank is minimized. Use a bottom ported Heavy Duty Ball Valve Pump to minimize settling while maximizing abrasion resistance. Use a bottom ported Heavy Duty Ball Valve Pump to minimize settling while maximizing abrasion resistance. A Heavy Duty Flap Valve Pump has unparralleld suction lift capabilty and is ideal for handling viscous and high...

Open the catalog to page 4

Warren Rupp Signature Design Platform An industry exclusive performance GUARANTEE! GUARANTEED not to yield under u Tension u Compression u Bending u Pump Operation Pressure Exhaust Stroke Pilot/Boost Cross-Drilled Pressure Pressure Port GUARANTEED NON-STALLING AIR VALVE PERFORMANCE If aWarrenRuppESADS+Plus®(ExternallyServiceable AirDistribution System) EVER* failstooperateorrestartaftershutdowndueto“centering”of themainairvalveorpilot valve,WarrenRupp will replace the air drive system free of charge. HavingsuppliedthisUPGRADED,FIELD PROVEN,RETROFITABLE,airdrivesystem since1996,the...

Open the catalog to page 5

Over 40 Years Ceramic Industry Experience! 800 North Main Street Mansfield, OH 44902-1568 USA 419-524-8388 • Fax: 419-522-7867 info.warrenrupp@idexcorp.com www.warrenrupp.com ®SANDPIPER and ESADS+Plus are registered trademarks of Warren Rupp, Inc. ©Copyright 2006. All rights reserved. SPCER-REV0107 Glaze Spray Gravity Casting Mixing Tanks

Open the catalog to page 6All WARREN RUPP catalogs and technical brochures

-

Versa-Matic Catalog

29 Pages

-

VERSA-MATIC

2 Pages

-

HDB3/HDB4 Metallic

9 Pages

-

HDB2 Metallic

6 Pages

-

S1F Metallic

7 Pages

-

S30 Non-Metallic

4 Pages

-

SA1 & SA25

7 Pages

-

E40 1-1/2" Metallic

4 Pages

-

E8 Non-Metallic

2 Pages

-

S15 Non-Metallic

6 Pages

-

S30 Metallic

7 Pages

-

PB1/4" Non-Metallic

7 Pages

-

HDF1 Metallic

6 Pages

-

ST1 / ST25 Metallic

6 Pages

-

E02 Metallic

2 Pages

-

U2 series

7 Pages

-

Air filter / regulAtor

2 Pages

-

W15 series

2 Pages

-

W09 -2 / W09-3

2 Pages

Archived catalogs

-

Company Brochure (2012 Edition)

36 Pages

-

B15_Stainless

2 Pages

-

B15_PTFE

2 Pages

-

B10_Non-Metallic

2 Pages

-

B06_X06_FDA

2 Pages

-

B06_Metallic

2 Pages

-

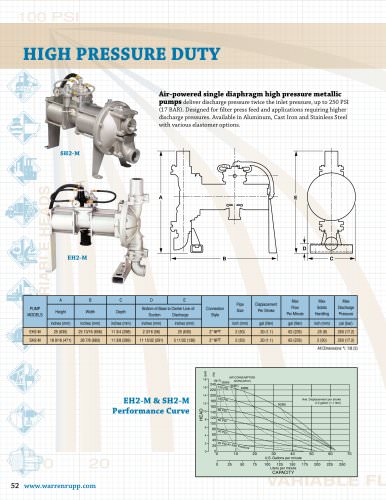

High Pressure Duty

3 Pages

-

Submersible Pumps

1 Pages

-

Standard Duty Metallic Pumps

2 Pages

-

Special Duty-UL Pumps

1 Pages

-

Natural Gas Operated Pumps

2 Pages

-

Special Duty-USDA Pumps

1 Pages

-

Mine/Construction Pumps

8 Pages

-

Heavy Duty Flap Pumps

2 Pages

-

Heavy Duty Ball Pumps

2 Pages

-

Duty Ball Pumps

2 Pages

-

Sandpiper Brochure

72 Pages

-

Marathon Brochure

16 Pages

-

Accessories and Controls

8 Pages