Website:

WANGEN PUMPEN

Website:

WANGEN PUMPEN

Group: Atlas Copco Group

Catalog excerpts

Part of the Atlas Copco Group Twin screw pump The new generation WANGEN Twin.

Open the catalog to page 1

The latest WANGEN Twin generation Perfect form and technology Maximum service friendliness • Spindle replacement without the need to re-synchronise the spindle shafts, thanks to fast-X-change® technology, developed by WANGEN PUMPEN (see pages 4 - 5). • Cartridge design for simple and quick seal replacement (see pages 6 - 7). • Coupling alignment by self-centring flange housing (lantern optionally available). Therefore no need for re-alignment of the coupling, for instance after service work. Large pressure range 16 - 25 bar operating pressure (depending on the pump size and design)....

Open the catalog to page 2

Pump media (examples) Food: Beverages: pure juice, concentrate, mash, pulp, yeast. Dairy products: yoghurt, quark, cheese, custard, butter. ketchup, mayonnaise, mustard, soup, salad dressings. chocolate, fondant, liquid sugar, rework, sugar, dough. strawberries, blueberries, cherries. minced meat, roast, animal feed. Cosmetics: Care products: creams, ointments, lotions. Cleaning products: soaps, shampoos, shower gels. Chemical products: Coatings: paints, varnishes. Bonding products: adhesives, glues, binders. suspensions, solutions, additives.

Open the catalog to page 3

Pioneering user-friendliness The WANGEN fast-X-change® system Changing spindles has always involved lengthy and stressful work with conventional industry solutions, associated with time-consuming and relatively high-cost service work, as the spindles always needed to be re-synchronised. This is now a thing of the past, thanks to fast-X-change® technology, developed by WANGEN PUMPEN. 80% time savings over conventional technologies Massively reduced working time and downtime alone Massive savings in the event of a service. Ultra-simple spindle replacement Spindles can now be replaced without...

Open the catalog to page 4

Exposed model: Twin NG 104

Open the catalog to page 5

Seal in real cartridge design Ultra-fast seal replacement It couldn’t be simpler: old seal cartridge out, new seal cartridge in. The superior design concept of the new generation WANGEN Twin is also visible here. The functionality of the seal can optionally also be restored using the WANGEN PUMPEN spare parts kit. Maximum service friendliness The ultimate aim with the design of the Twin NG was to achieve absolute ease of service, based on the “one step ahead” slogan. It also goes without saying that the WANGEN Twin NG simultaneously needs to meet WANGEN PUMPEN’s traditionally high quality...

Open the catalog to page 6

Exploded view of the WANGEN Twin NG cartridge seal

Open the catalog to page 7

Two pumps in one As with twins, you also have twice the joy with the WANGEN Twin NG: it can be used as both a product and CIP pump. You therefore have no additional costs for a separate centrifugal pump, bypass line, valves and measuring, control and regulation technology. water Product Pumping and cleaning with one pump: WANGEN Twin NG 130 Cleaning: 1460 rpm, 2 bar and 36 m³/h Tomato paste: 380 rpm, 8 bar and 10 m³/h Pumping with a displacement pump and CIP cleaning with a centrifugal pump Pumping and CIP cleaning with the WANGEN Twin NG With the WANGEN Twin NG, you can add the water...

Open the catalog to page 8

Hygienic highlights Top hygienic values Other highlights The WANGEN Twin NG achieves top marks with • Pump can be installed independently SIP and CIP cleaning. This is due, above all, to the following characteristics of the WANGEN Twin NG, unique in this combination: • 100% backward compatible with the previous WANGEN Twin generation. • Grey cast iron bearing housing (galvanised • Extremely high speed range enables either product or cleaning fluid to be pumped • High speeds in cleaning mode ensure selfcleaning success in the pump • Lines, equipment and fittings filled with product with a...

Open the catalog to page 9

Technical data Characteristics High suction lift Axial pumping and the slow acceleration of the Axial pumping and slow acceleration in the pump product in the pump ensure excellent suction also ensure low pulsation. Any pulsation produced is quickly eliminated by high speeds • Emptying tanks • Minimal shearing forces retain the structure and • In the event of minimal feed height to the pump • For the pumping of viscous or slightly simmering products appearance of the products • Ensures the gentle pumping of sensitive media • Extension of the pump line by connection of pumps in series...

Open the catalog to page 10

Technical data WANGEN Twin NG performance data Pump size Maximum free passage (mm) Max. pump volume (m³/h) at a viscosity of 1 mPa·s Maximum peak pressure (bar) Twin NG 104 with lantern Twin NG 130 with lantern Twin NG 70, with stainless steel cover Twin NG 180 with standard coupling protection *) 3A applies to WANGEN Twin NG 70 3-A, 104 3-A, 130 3-A. EHEDG applies to WANGEN Twin NG 70, 104, 130, 180.

Open the catalog to page 11

Part of the Atlas Copco Group WANGEN Twin NG 104, on baseplate with adjustable feet WANGEN Twin NG technical details: Max. pump capacity: 200 m3/h Viscosity: WANGEN PUMPEN is certified to: ISO 9001 (Quality management) No. ED602 ISO 14001 (Environmental management) ISO 45001 (Occupational safety and health protection) Pumpenfabrik Wangen GmbH Simoniusstrasse 17 88239 Wangen im Allgäu Technical advice: Service hotline: Spare parts: © 2023 Pumpenfabrik Wangen GmbH. Subject to errors and technical modification. Your contact

Open the catalog to page 12All WANGEN PUMPEN catalogs and technical brochures

-

WANGEN Hygienic

2 Pages

-

WANGEN Product overview

24 Pages

-

WANGEN A/ GL-F/ GL-S

12 Pages

-

WANGEN VarioTwin NG

4 Pages

-

WANGEN HYLINE

4 Pages

-

WANGEN KB-S/ KL-S

12 Pages

-

WANGEN KB22S

2 Pages

-

WANGEN KL-R

8 Pages

-

WANGEN KL-T / KB-T

8 Pages

-

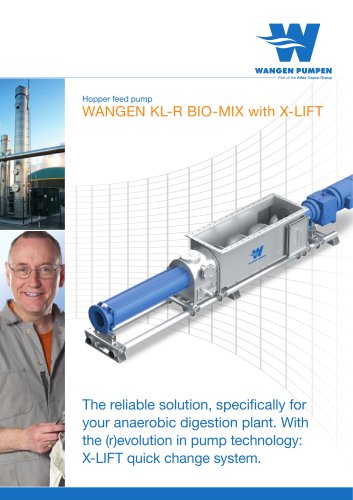

WANGEN KL-R BIO-MIX

12 Pages

-

WANGEN Xpress

12 Pages

-

WANGEN BIO-FEED

4 Pages