Website:

WANGEN PUMPEN

Website:

WANGEN PUMPEN

Group: Atlas Copco Group

Catalog excerpts

Part of the Atlas Copco Group Immersion pumps For conveying media from containers and vats

Open the catalog to page 1

Immersion pumps KL-T, KB-T In order to ensure the highest operating safety as possible, WANGEN PUMPEN only uses the best materials and components for the intended purpose. Our many years of experience in the conveyance of a variety of mediums ensures a design that meets modern requirements. Thanks to the vertical construction form, the WANGEN Technical highlights: KL-T / KB-T has only a small space requirement. The consistent diameter of the joint connections ensures constant flow speeds and reduces the Maximum differential pressure 12 bar, sensitivity to foreign materials. The...

Open the catalog to page 2

Conveying Materials Amongst other things, the following media can be typically pumped using the hygienic or standard versions of the KL-T immersion pump: • Fruit juices • Honey and jams • Dairy products such as milk or yoghurt • Food products such as chili sauce, olive paste, tomato paste, proteins, chocolate or bisquit dough • Soup spices, soy oil, mustard, ketchup, mayonnaise • Biogas substrates from mines • Paints and laquers • Calcium carbonate, chromium hydroxide and hydrogen peroxide • Paper pulp • Glycerin, vaseline and soap • Pomace • Sewage, coal flotation and refined sludge •...

Open the catalog to page 3

Low Life-Cycle Costs When purchasing a pump, we recommend that you carefully consider the operating costs as well as the costs for the initial outlay. Maintenance costs, production downtimes and energy costs make up a considerable share of the total costs over the life-cycle of a pump. In this case, a decisive advantage of our philosophy becomes apparent: in order to keep total costs as low as possible over the entire life-cycle of the pump, our approach is to restrict the frequency of maintenance to a minimum. This can be achieved due to the robust construction of our pumps, the use of...

Open the catalog to page 4

Technical Data Options and Accessories We offer a large selection of accessories, which are perfectly matched to our product range, providing the ideal complement or adaptation to your individual requirements and allowing you to create your own customized solutions. We would be also happy to assist you with special solutions. • Homogeniser for mixing • Fugator for deterring foreign bodies • Mounting flange • Mounting bracket • Three-point set up KL-T in operation with mounting bracket and three-point set up Spare Parts By using spare parts from WANGEN PUMPEN, we guarantee that the...

Open the catalog to page 5

Technical Data Models and Materials In order to ensure the highest operating safety as possible, WANGEN PUMPEN only uses the best materials and components for the intended purpose. Our many years of experience in the conveyance of a variety of mediums ensures a design that meets modern requirements. • Casing, pressure and suction flange: Grey cast iron, construction steel 1.0038, stainless steel 1.4301, stainless steel 1.4571 • Joints: stainless steel cardan joints, optionally with sleeve • Seals: Mechanical face seals, shaft seals, stuffing box packing, single and double-effect mechanical...

Open the catalog to page 6

Technical Data Performance Data KL-T The KL-T series has a robust bearing pedestral with For optimal filling of the pumping chamber, the sta- a direct flanging and self-centering drive. In this way, tor has a funnel-shaped input. The specially tested sufficient reserve forces are available, also in the sealing system of Wangen Pumpen contributes to the case more sophisticated media. high operational safety. Pump size Maximum free ball passage (mm) Maximum differential pressure (bar) KL-T stainless steel version

Open the catalog to page 7

Part of the Atlas Copco Group WANGEN PUMPEN is certified to: Nr. ED609 ISO 9001 (Quality management) ISO 14001 (Environmental management) Your contact: Pumpenfabrik Wangen GmbH Simoniusstrasse 17 88239 Wangen im Allgäu Service hotline: Spare parts: © 2023 Pumpenfabrik Wangen GmbH. We reserve the right to error and technical changes. ISO 45001 (Occupational safety and health protection)

Open the catalog to page 8All WANGEN PUMPEN catalogs and technical brochures

-

WANGEN Hygienic

2 Pages

-

WANGEN Product overview

24 Pages

-

WANGEN A/ GL-F/ GL-S

12 Pages

-

WANGEN VarioTwin NG

4 Pages

-

WANGEN Twin NG

12 Pages

-

WANGEN HYLINE

4 Pages

-

WANGEN KB-S/ KL-S

12 Pages

-

WANGEN KB22S

2 Pages

-

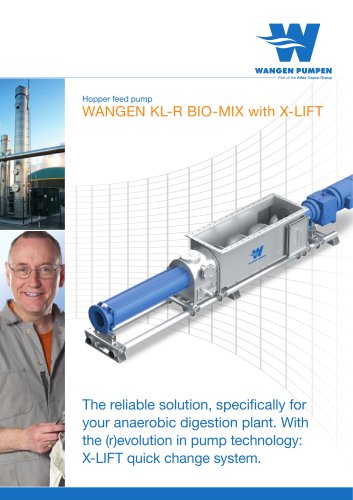

WANGEN KL-R

8 Pages

-

WANGEN KL-R BIO-MIX

12 Pages

-

WANGEN Xpress

12 Pages

-

WANGEN BIO-FEED

4 Pages