Website:

WANGEN PUMPEN

Website:

WANGEN PUMPEN

Group: Atlas Copco Group

Catalog excerpts

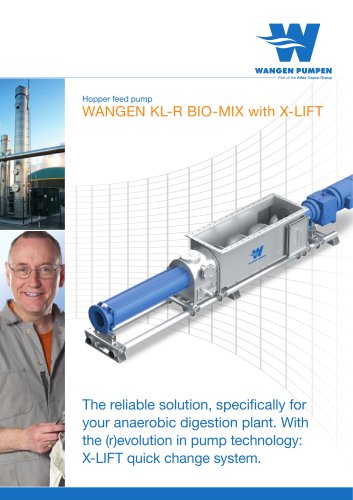

Part of the Atlas Copco Group Hopper feed pump The reliable solution, specifically for your biogas system

Open the catalog to page 1

Hopper feed pump KL-R BIO-MIX The WANGEN BIO-MIX pumps have been integrated in the process of energy production for years and have been constantly developed and optimized. They are suitable for corn and grass silage, solid and liquid manure, as well as waste and are mixed with fluids in the pump. The KL-R BIO-MIX is able to cope with long dis- Technical highlights: tances and height differences. The wear-protected cardan joints, in conjunction with the worm pre-con- veyor are extremely resistant to foreign bodies and contribute to the long lifetime of the pumps. High solids content of up to...

Open the catalog to page 2

Conveying Materials With the hopper pump KL-R BIO-MIX, the following media types are typically conveyed: • Fruit, such as apples or pears • Fish waste • Slaughterhouse waste • Food waste • Whole plant silage • Cereal shreds • Grass • Corn silage • Recirculated products • Pomace • Sugar beets • Liquid manure, also chi

Open the catalog to page 3

Construction Characteristics Simple filling of the hopper due to the generous dimensions Separation of foreign bodies and removal of such via large inspection openings Large inspection flaps for easy access to the tunnel area Supports right and left for variable connection of fluid feed for mashing Large inspection flap or cleaning lid with supports for rinsing, cleaning of draining of fluids. Integrated stone collection container shows that they have consistently been designed for performance and reliability. In this way, the stone catching container is extended across the entire hopper...

Open the catalog to page 4

We always have the overall process in mind We see ourselves not just as a supplier of individual components. Our objective is rather to find the best solution for the entire production process. We achieve this by exact observation and analysis of the overall process, not just a part of it. You receive a solution that has been precisely assessed and prepared by the WANGEN PUMPEN specialists. Whether complex or simple, we guarantee the best possible integration of our machines into your existing or new plant system. You will not only profit from our expertise in mechanical engineering, but...

Open the catalog to page 5

Maximum Variability WANGEN progressing cavity pumps have a modular We offer the optimum solution for your applica- design. A multitude of standardised construction tion and can provide a maximum efficient pumping parts is available for each series and enables each solution for your business, regardless of the industry pump to be adapted to meet your specific pumping requirements. Maximum variability means • Various construction sizes and rotor/ stator sizes mean more than 100 models of the compact pump with a delivery rate ranging from 20 m3/h up to large pumps, which can handle flowrates...

Open the catalog to page 6

Low Life Cycle Costs When purchasing a pump, we recommend that you carefully consider the operating costs as well as the costs for the initial outlay. Because maintenance costs, production downtimes and energy costs make up a considerable share of the total costs over the life-cycle of a pump. In this case, a decisive advantage of our philosophy becomes apparent: in order to keep total costs as low as possible over the entire life-cycle of the pump, our approach is to restrict the frequency of maintenance to a minimum. This can be achieved thanks to the robust construction of our pumps, the...

Open the catalog to page 7

Technical Data Models and Materials There is a large selection of standardised construction parts available for the design of your standard suction pump. We provide economical and optimised pumping solutions that are tailor-made for your branch of industry and operating conditions. • Casing, pressure and suction flange: Stainless steel 1.4301, stainless steel 1.4571 • Joints: stainless steel cardan joints • Seals: single and double-effect mechanical seals • Stators: diverse NBR materials, FPM, silicon, EPDM, pressure-stable 'even wall' designs, solid substance stators made of POM • Rotors...

Open the catalog to page 8

Technical Data Models and Materials WANGEN PUMPEN only uses the best materials and components to ensure high operating safety. Due to our many years of experience in this industry, we guarantee a design that meets modern requirements. The standard version HDS of the KL-R BIO-MIX is supplied with a round hopper and stone collection container after the feed screw. The HD version is fitted with a square hopper. The advantage of this method of construction is that the entire length of the hopper is used as a stone coll- HDS version with round hopper (standard) ector and the foreign bodies...

Open the catalog to page 9

Technical Data Options and Accessories We offer a large selection of accessories which are perfectly matched to our product range, providing the ideal complement or adaptation to your individual requirements and allowing you to create your own customized solutions. We would be happy to assist you with customised solutions. . • Hoppers available in a variety of sizes • Hoppers in stainless steel • Feed screws in steel or stainless steel • Optionally with base plate • Special versions possible for adaptation to existing systems • and much more Hopper round, stainless steel Easy Maintenance...

Open the catalog to page 10

Technical Data Performance Data KL-R BIO-MIX Pump size Maximum free ball passage (mm) Maximum differential pressure (bar) Large inspection and cleaning openings KL-R BIO-MIX on galvanised steel tube frame

Open the catalog to page 11

Part of the Atlas Copco Group WANGEN PUMPEN is certified to: ISO 9001 (Quality management) Nr. ED607 Your contact: Pumpenfabrik Wangen GmbH Simoniusstrasse 17 88239 Wangen im Allgäu Service hotline: Spare parts: © 2024 Pumpenfabrik Wangen GmbH. We reserve the right to error and technical changes. ISO 45001 (Occupational safety and health protection)

Open the catalog to page 12All WANGEN PUMPEN catalogs and technical brochures

-

WANGEN Hygienic

2 Pages

-

WANGEN Product overview

24 Pages

-

WANGEN A/ GL-F/ GL-S

12 Pages

-

WANGEN VarioTwin NG

4 Pages

-

WANGEN Twin NG

12 Pages

-

WANGEN HYLINE

4 Pages

-

WANGEN KB-S/ KL-S

12 Pages

-

WANGEN KB22S

2 Pages

-

WANGEN KL-R

8 Pages

-

WANGEN KL-T / KB-T

8 Pages

-

WANGEN Xpress

12 Pages

-

WANGEN BIO-FEED

4 Pages