Website:

WANGEN PUMPEN

Website:

WANGEN PUMPEN

Group: Atlas Copco Group

Catalog excerpts

Part of the Atlas Copco Group Hygienic self priming and hopper feed pumps HYLINE, KB-SL, KL-SL, KL-RL, KL-RF, KL-TL / KB-TL / MX For hygienic pumping processes with low to extremely high viscosity media

Open the catalog to page 1

WANGEN hygienic self priming and hopper feed pumps HYLINE, KB-SL, KL-SL, KL-RL, KL-RF, KL-TL / KB-TL, A high degree of automation and fast product turn- As varied as the requirements, provisions, and areas over are characteristics of the modern meat proces- sing industry. Fruits and vegetables depend on fresh- lutions. However, one important point remains the ness and quality. The confectionery industry works same: satisfying the customers' highest quality re- with different kinds of ingredients, which vary from quirements and specifications, especially in terms of viscous to sticky, may...

Open the catalog to page 2

Conveying Materials The progressing cavity pumps of the series KB-SL, KL-SL, KL-RL, KL-RF and KL-TL/KB-TL are typically used to pump the following mediums: • Apples, pears, and other fruit • Vegetables • Grain and/or coarsely ground cereal • Pastes • Dairy products, such as butter, milk, yoghurt, ice cream, processed cheese • Meat varieties and tofu • Honey, caramel, gelatine, jam • Confection, such as chocolate, liquid sugar, marzipan or waffel mass • Beverages, such as fruit juices, beer • Mustard, ketchup, soy sauce, tomato paste or mayonnaise • Cosmetics, such as

Open the catalog to page 3

We always have the overall process in mind We see ourselves not just as a supplier of individual components. Our objective is rather to find the best solution for the entire production process. We achieve this by exact observation and analysis of the overall process. You receive a solution to match your requirements that was precisely assessed and prepared by the specialists from WANGEN PUMPEN. Whether complex or simple: We guarantee the best possible integration of our machines into your existing or new plant system. Here you will not only profit from our know-how in mechanical engineering...

Open the catalog to page 4

Highest standards of hygiene We take our responsibility towards humanity very se- We achieve this by using consistent and uncom- riously, especially when it comes to hygienic pumps. promising production according to the highest hy- For this reason, particular importance is placed on giene standards. This also includes the special de- the highest precision and care in the production pro- sign and surface characteristics of our pumps and cess at WANGEN PUMPEN. It is our goal to make their assemblies, which avoids producing deposits the entry of bacteria and germs into our pumps as forming in...

Open the catalog to page 5

Construction Characteristics Bearing pedestal with self-centering and direct flange-fitting of the drive unit. This avoids damage to the gearbox. Main sealing material washed optimally within the product room as a mechanical seal. Cardan shaft and joints in stainless steel, open design for ease of cleaning ability shows that they are consistently built for performance and reliability. For example, pumps of the KBSL series are manufactured as a block construction, which completely suffices Robust rotor of the highest quality from our own production available in various shapes for media which...

Open the catalog to page 6

Maximum Variability WANGEN progressing cavity pumps have a modu- work in, the medium to be pumped and your ope- lar design. A variety of standardized parts is availa- rational requirements: We offer the optimum solu- ble for each series and enables each pump to be tion for your application, regardless of the industry adapted to meet your specific pumping requirements. you work in, the medium to be pumped, and your Regardless of whatever branch of industry you operational requirements. Maximum variability: • Various construction sizes and rotor/ stator sizes mean more than 100 models of the...

Open the catalog to page 7

Low Life-Cycle Costs When purchasing a pump, we recommend that you carefully consider the operating costs as well as the costs for the initial outlay. Because maintenance costs, production downtimes and energy costs make up a considerable share of the total costs over the life-cycle of a pump. In this case, a decisive advantage of our philosophy becomes apparent: in order to keep total costs as low as possible over the entire life-cycle of the pump, our approach is to restrict the frequency of Because every breakdown that can be avoided sa- maintenance to a minimum. This can be achieved ves...

Open the catalog to page 8

Technical Data Versions and Materials There is a large selection of standardised construction parts available for the design of your standard suction pump. We provide economical and optimised pumping solutions that are tailor-made for your branch of industry and operating conditions. • Casing, pressure and suction flange: Stainless steel 1.4301, stainless steel 1.4571 • Joints: stainles steel cardan joints, optionally with sleeve • Seals: single and double-effect mechanical seals • Stators: diverse NBR materials, FPM, silicon, EPDM, pressure-stable 'even wall' designs, solid substance...

Open the catalog to page 9

Technical Data Performance Data HYLINE The WANGEN HYLINE is designed by WANGEN The flexible and maintenance-free joint is coated PUMPEN to ensure optimal performance and with elastomer and offers almost no weak operational reliability. The inner geometry of the spots for disposals of the media to be pumped. housing is designed fully hygienically and, as is In order to enable the conveyance of a wide usual with WANGEN PUMPEN, suited to long life. spectrum of media, a large selection of shaft seals are available for the HYLINE. Pump size Maximum free ball passage (mm) Maximum differential...

Open the catalog to page 10

Technical Data Performance Data KL-TL / KB-TL The WANGEN progressing cavity pump type KL-TL / pulsating and continuous pumping action of the KB-TL is suitable as an immersion pump for pum- media is independent of pressure and viscosity. A ping mediums out of tanks and basins. Regardless further benefit is the high level of operating safety. of the medium's consistency, it is convoyed as The configuration and length of the pump can be careful as possible without impairing its structure customized to meet the needs of the client. and quality. The joint connections retain an uniform diameter...

Open the catalog to page 11All WANGEN PUMPEN catalogs and technical brochures

-

WANGEN Hygienic

2 Pages

-

WANGEN Product overview

24 Pages

-

WANGEN A/ GL-F/ GL-S

12 Pages

-

WANGEN VarioTwin NG

4 Pages

-

WANGEN Twin NG

12 Pages

-

WANGEN HYLINE

4 Pages

-

WANGEN KB-S/ KL-S

12 Pages

-

WANGEN KB22S

2 Pages

-

WANGEN KL-R

8 Pages

-

WANGEN KL-T / KB-T

8 Pages

-

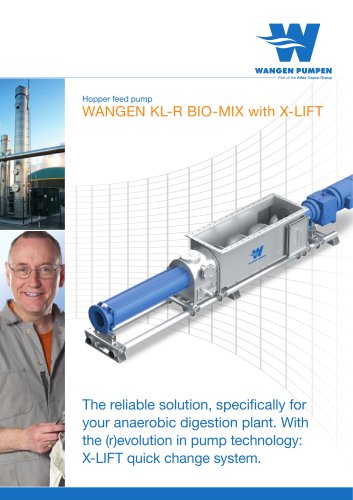

WANGEN KL-R BIO-MIX

12 Pages

-

WANGEN Xpress

12 Pages

-

WANGEN BIO-FEED

4 Pages