Website:

WANGEN PUMPEN

Website:

WANGEN PUMPEN

Group: Atlas Copco Group

Catalog excerpts

Part of the Atlas Copco Group The robust solution for the conveyance of manure, sludge, and fermenter substrate

Open the catalog to page 1

WANGEN progressing cavity pumps PTO shaft pumps A, GL-F, GL-S WANGEN pumps can be driven via power take-off Technical highlights: as well as via electrical, hydraulic or diesel motor. According to requirements, they can be designed wagons. Alongside the three-point bracket mount, High solids content of up to 18% they may also be mounted directly to the manure tanker, for example, for the distribution of water, slurry, and thick mediums, such as manure or sludge. Then, they are driven directly via the power take-off profile connection of the tractor. Numerous versions, sizes, as well as...

Open the catalog to page 2

Conveying Materials With the power take-off pumps A, GL-F and GL-S, The power take-off pumps A, GL-F and GL-S the following mediums are typically convoyed: • Manure, from cattle or chickens • Sewage sludge • Fermenter substrate • Loading, unloading, transferring

Open the catalog to page 3

Construction Characteristics Main sealing in cartridge construction, quick and easy to replace. Large cleaning and inspection openings Cardan shaft and joints by default in GL-F. Lifelong permanently lubricated needle bearing. Wear and maintenance-free. Our aim is to produce the best pumps for the job in hand. For The robust rotor is produced in the highest quality at our own plant. It can be manufactured in various shapes. this reason, WANGEN pumps are consistently designed for the highest possible performance and reliability. This can be clearly seen by the construction and the and the...

Open the catalog to page 4

Maximum Reliability In agricultural operations, a medium is often conveyed with a high ratio of foreign objects, which often occurs at high pressure or continuous operation. This heavy load often leads to damages with traditional pumps, such as a breaking joints. For this reason, we only use robust components of the best-possible quality for our pumps. In this way, WANGEN pumps need less maintenance and enable an interruptionfree operation. • The bearing block takes the pressure off the joint shaft and prevents damage when used for continuous operation. • A non-clogging operation is ensured...

Open the catalog to page 5

Low Life-Cycle Costs When purchasing a pump, we recommend that you carefully consider the operating costs as well as the costs for the initial purchase. Maintenance costs, production downtimes, and energy costs make up a considerable share of the total costs over the lifecycle of a pump. Our philosophy is to keep the total costs of the entire pump life-cycle as low as possible by reducing needed maintenance to a minimum. This is possible due to our robust pump construction, the use of high quality wearing parts, and a wear-resistant design of the pumps. Every avoided breakdown saves you...

Open the catalog to page 6

Technical Data Models and Materials There is a large selection of parts available for the design of our standard suction pump. We provide economical and optimized pumping solutions that are customized for your industry and operating conditions. • Housing, pressure and suction flange: Grey cast iron, construction steel 1.0038, galvanised • Joints: stainless steel cardan joints, optionally with sleeve • Seals: Drive seals • Rotor: Hardened tool steel, stainless steel 1.4301 (A304), stainless steel 1.4571 (A314Ti), both available with chromium or chromium carbide coating • Stators: diverse NBR...

Open the catalog to page 7

Technical data Options and Accessories We offer a large selection of accessories, which are perfectly matched to our product range, providing the ideal complement or adaptation to your individual requirements and allowing you to create your own customized solutions. If you need a special solution, we would be happy to assist you. In order to increase the safety and flexibility, additional WANGEN pump accessories are available: • Pneumatic overflow unit • Hanging bar (GL-F) • Bypass • Optional equipment with multiple path slider • and much more Spare Parts By using spare parts from WANGEN...

Open the catalog to page 8

Technical Data Performance Data GL-F The WANGEN processing cavity pump of type GL-F The pump drive is provided by a power take-off is compactly built. It can be used to achieve high or a drive shaft with a feather key. The integrated conveyance volumes and counter pressures. At- winding protection mechanism prevents fibers from tached to tank trailers, slurry tankers and umbilical winding around the joint and joint connections. The hose systems, it is equally suited for mediums with large inspection and cleaning openings on the suc- different properties, such as fluid or slow-moving, tion...

Open the catalog to page 9

Technical Data Performance Data A Attached to slurry tankers, the WANGEN progres- tion chamber that switch the pump from suction to sing cavity pump of type A is suitable for distribu- pump mode. The pump is not sensitive to foreign ting water, slurry, and thick fluids, such as manu- objects and the deposition of foreign objects in re. The drive is implemented via a power take off the suction housing is not possible. In addition, profile that enables the pump to be easily coupled hollow rotors ensure quiet operation. to the tanker. It has swivel pushers inside the suc- Pump size Maximum...

Open the catalog to page 10

Technical Data Performance Data GL-S The WANGEN progressing cavity pump of type GL-S They carry watery or thick media, as well as media is particularly well suited to umbilical hose systems. loaded with solids just as well. WANGEN pumps of Large distances and height differences are maste- type GL-S are primarily used in agriculture. red easily. It may be used as a stationary pump or mobile pump, attached to a slurry tanker or chassis. The comprehensive range of pumps available make them a product for universal use. Pump size Maximum completely free passage (mm) Maximum differential pressure...

Open the catalog to page 11

Part of the Atlas Copco Group WANGEN PUMPEN is certified to: Nr. ED608 ISO 9001 (Quality management) ISO 14001 (Environmental management) Your contact: Pumpenfabrik Wangen GmbH Simoniusstrasse 17 88239 Wangen im Allg. Service hotline: Spare parts: © 2023 Pumpenfabrik Wangen GmbH. We reserve the right to error and technical changes. ISO 45001 (Occupational safety and health protection)

Open the catalog to page 12All WANGEN PUMPEN catalogs and technical brochures

-

WANGEN Hygienic

2 Pages

-

WANGEN Product overview

24 Pages

-

WANGEN VarioTwin NG

4 Pages

-

WANGEN Twin NG

12 Pages

-

WANGEN HYLINE

4 Pages

-

WANGEN KB-S/ KL-S

12 Pages

-

WANGEN KB22S

2 Pages

-

WANGEN KL-R

8 Pages

-

WANGEN KL-T / KB-T

8 Pages

-

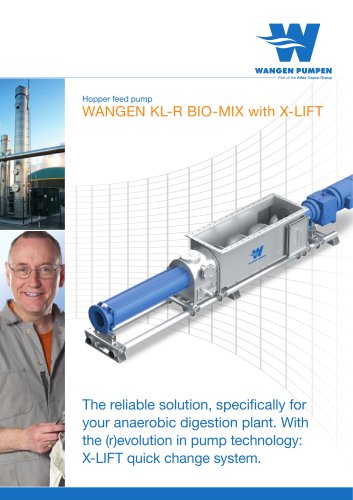

WANGEN KL-R BIO-MIX

12 Pages

-

WANGEN Xpress

12 Pages

-

WANGEN BIO-FEED

4 Pages