Catalog excerpts

Robot Sword Brush Laura 160.. Brief description The Robot Sword Brush Laura 160..cleans complex geometrical surfaces such as car bodies, support structures or plastic moulded parts prior to painting or coating. It features two parallel linear brushes that are mounted on a flexible contact area. They have micro-moistened filament tips that allow them to remove very fine dust particles without dampening the subject surface. Between the two linear brushes, there are rotating Tornado nozzles that use a jet of compressed air to remove particles from recesses. The combination of brushes and nozzles provides for an excellent cleaning result and allows fast cycle times. Technical details - 2 x linear brush Quadro L with flexible pressure buffer that is controlled pneumatically - Ingromat®-System - Rotating Tornado nozzles TEN 50 D with speed control - Crash sensors, standstill monitor, flow meter - Fieldbus system (e.g. Profibus) - Compact hub drive - Robot flange with quick change system Flexible working area Pmax* = A - 310 = 690 (for convex surfaces) Pmax* = A - 160 = 840 (for concave surfaces) A = 1000 (Nominal width) 1326 * Pmax = maximum cleaning width Values

Open the catalog to page 1

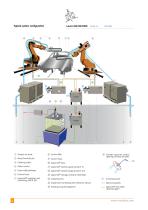

© Subject car body (2) Robot Sword Brush (3) Cleaning robot (4) Motor control (5) Hose cable package @ Suction hose (7) Ingromat® regulator and monitoring unit IR 160 (8) Suction filter (9) Suction hose ® Ingromat® hose CD) Ingromat® central supply pump IS 14 ® Ingromat® central supply pump IS 12-2 @ Ingromat® storage container 1000 litres (0) Collecting tray ® Liquid level monitoring with ultrasonic sensor ® Isolating module Vegatrenn ® Tornado nozzle for cyclical cleaning of linear brushes O— Compressed air Electrical signals — Ingromat® anti-static cleaning agent

Open the catalog to page 2

Ingromat® sprayer Robot flange to micro-moisten linear with quick change system Two linear brushes type Quadro L Tornado nozzles TEN 50 D with speed control Flexible pressure buffer (Approx. 700-800 rpm) Crash sensor Hub drive Self-cleaning mechanism flexible adjustment to wavy surfaces Ingromat® system CD Micro-moistening of brush filaments with antistatic cleaning agent Ingromat® (D Brush cleaning of product surface: Particles cling to brush filaments and are transported towards suction system (D Mechanical self-cleaning of circulating linear brush: Particles are detached from brush...

Open the catalog to page 3

Laura 160.. Electrical details Drive Voltage Output Protection Pneumatic details Compressed air consumption Compressed air quality Compressed air connection Suction Suction connection Suction capacity Acoustic emission Hub drive; stabilised 10 A power supply unit necessary 48 V DC 0.13 kW IP 55 250 l/min, (without Tornado nozzles), 1550 l/min (with Tornado nozzles) filtered (particle size < 40pm), oil free (residual oil < 1.5 mg/m3 at 24° C) 6 bar,; 1 x 0 10 mm (Linear brushes); 1 x 0 16 mm (Tornado nozzles) 1 x 0 80 mm 8 m3/min (at recommended flow velocity 25 m/s) Approx. 75 dB (A)...

Open the catalog to page 4All Wandres GmbH micro-cleaning catalogs and technical brochures

-

Tornado Nozzle Janus 50 D

2 Pages

-

Sword Brush BIX 51

4 Pages

-

PCL-Cleaner 121

4 Pages

-

Cevomat TM CVOC 17

4 Pages

-

Cevomat TM CVO 17

4 Pages

-

Evomat™ EVO 500

2 Pages

-

Robot Sword Brush

4 Pages