Catalog excerpts

FENCE & DECKING SPRAYER gft ORIGINAL-BETRIEBSANLEITUNG OWNERS MANUAL

Open the catalog to page 1

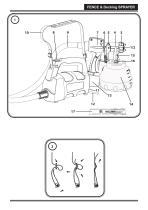

FENCE & Decking SPRAYER 1 8

Open the catalog to page 2

FENCE & Decking SPRAYER 4

Open the catalog to page 3

FENCE & Decking SPRAYER 6

Open the catalog to page 4

FENCE & Decking SPRAYER

Open the catalog to page 5

FENCE & Decking SPRAYER GB Fragen? · Questions? · Des questions? · V

Open the catalog to page 6

FENCE & Decking SPRAYER Translation of the original operating instructions MANY THANKS FOR PLACING YOUR TRUST IN US We would like to congratulate you on purchasing this brand product from Wagner; we are sure that you will enjoy working with it greatly. Please read the Operating Manual carefully and observe the safety information before starting the device. Store the Operating Manual in a safe place close to the product in case it needs to be used by someone else. We would be happy to be of assistance if you have any questions, suggestions or requests. Please contact us via the phone number...

Open the catalog to page 7

FENCE & Decking SPRAYER 2. General Safety Instructions WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference. The term "power tool" in the warnings refer to your mains-operated (corded) power tool or battery-operated (cordless) power tool. 1. Work area safety a) Keep work area clean and well lit. Cluttered or dark areas invite accidents. b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable...

Open the catalog to page 8

FENCE & Decking SPRAYER c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock. d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock. e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock. f) If operating a power tool in a damp location is...

Open the catalog to page 9

FENCE & Decking SPRAYER b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired. c) Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally. d) Store idle power tools out of reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power...

Open the catalog to page 10

FENCE & Decking SPRAYER • Do not spray any liquid of unknown hazard potential. • The device may not be used in workplaces covered by the explosion-protection regulations. • To avoid the hazard of explosion when spraying, provide for effective natural or artificial ventilation. • There must be no sources of ignition such as, for example, open fires, smoke of lit cigarettes, cigars and tobacco pipes, sparks, glowing wires, hot surfaces, etc. in the vicinity during spraying. • Ensure that no solvent vapors are sucked in by the unit. Do not spray onto the unit! • The spray gun is not a toy;...

Open the catalog to page 11

FENCE & Decking SPRAYER 6. Coating Materials Not Suitable for Use Wall paints without the red Perfect Spray logo. Materials that contain highly abrasive components, plaster, facade paint, caustic solutions and acidic coating substances. Flammable materials. 7. Preparation of the Coating Material The enclosed spray attachment can be used to spray paints, varnishes and glazes that are undiluted or slightly diluted. Detailed information is available in the technical data sheet of the manufacturer (^ Internet Download). 1. Stir the material up and put the required amount into the paint...

Open the catalog to page 12

FENCE & Decking SPRAYER • Put the machine down only on a level, clean surface. Otherwise, the gun may suck in dust, etc. • Sling on the carrying strap with the unit. • Remove the spray gun from the gun holder and point it at the object to be coated. • I t is advisable to test spray cardboard or a similar material in order to determine the material quantity and the spray pattern. • Press the ON/OFF switch at the device. 9. Adjusting the desired Spray Setting WARNING! Danger of injury! Never pull the trigger guard while adjusting the air cap. With the union nut (fig. 7, 1) slightly unscrewed,...

Open the catalog to page 13

FENCE & Decking SPRAYER • Move the spray gun evenly cross-wise or up-and-down, depending on the spray pattern setting. • An even movement of the spray gun results in an even surface quality. • When coating material builds up on the nozzle and air cap, clean both parts with a solvent or water. 12. Interruption of Work till 4 Hours • Turn the machine off. • Insert the spray gun into the gun holder. • When processing 2-component varnishes, clean the device immediately. 13. Taking Out of Operation and Cleaning Proper cleaning is the prerequisite for problem-free operation of the paint...

Open the catalog to page 14

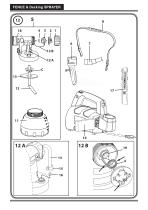

FENCE & Decking SPRAYER Assembly The unit may only be operated with an integer diaphragm (Fig. 12 A, 16). 1) Place the diaphragm (Fig. 12 A, 16) with the pin facing upwards on the bottom section of the valve. Also see the marking on the gun body. 2) Place on the valve cover (Fig. 12 A, 15) and screw it closed. 3) Place the ventilating hose (Fig. 12 A, 14) on the valve cover and on the nipple at the gun body. 4) Push the nozzle seal (fig. 12 B, 4) over the needle (19); the groove (slot) should point towards you. 5) Put the nozzle onto the gun body and find the correct position by turning it....

Open the catalog to page 15

FENCE & Decking SPRAYER

Open the catalog to page 16

FENCE & Decking SPRAYER Measured in accordance with EN 60745-1 Information about the oscillation level The specified oscillation level has been measured according to a standard test procedure and can be used to compare against electric tools. The oscillation level is also for determining an initial assessment of the vibrational strain. Attention! The vibration emission value can differ from the specified value when the electric tool is actually in use, depending on how the electric tool is being used. It is necessary to specify safety measures to protect the operating personnel. These...

Open the catalog to page 17All WAGNER catalogs and technical brochures

-

Brochure PEM-X1 CG

4 Pages

-

Brochure Manual application

3 Pages

-

Corona and Tribo Guns

10 Pages

-

Brochure Cobra

4 Pages

-

Press release IceBreaker

3 Pages

-

STATIONARY Wood- & Metalworking

11 Pages

-

Manual powder coating

3 Pages

-

PXS Powder Centers

2 Pages

-

TOPFINISH DD10

2 Pages

-

C-Line

6 Pages

-

WOOD- & METALWORKING

12 Pages

-

Unica AME

4 Pages

-

Flyer EvoMotion-Revers AME

2 Pages

-

WAG Datenblatt DD10 GER

2 Pages

-

BROSCHÜRE COBRA AME

8 Pages

-

DD10

2 Pages

-

Control Pro 350 R

144 Pages

-

Control Pro 350 M

144 Pages

-

Control Pro 250 M

140 Pages

-

W 990 FLEXiO

122 Pages

-

W 950 FLEXiO

130 Pages

-

FineCoat 9900

6 Pages

-

FineCoat 9900 PowerCart

52 Pages

-

Zip 52

68 Pages

-

FinishControl 5000

132 Pages

-

FinishControl 3500

132 Pages

-

Basic Booth Systems

2 Pages

-

SuperCube

4 Pages

-

Prima Cube

4 Pages

-

ID-Booth System LV

4 Pages

-

Profi Tech M

8 Pages

-

Profi Tech S

6 Pages

-

Prima Tech CCM

4 Pages

-

Facades and interior walls

12 Pages

-

SuperFinish

5 Pages

-

Finish Control 5000

2 Pages

-

PROTEC GM

2 Pages

-

WOOD & METAL APPLICATIONS

7 Pages

-

BO AIRSPRAY-MANUAL AME

8 Pages

-

BO GM 4000AC AME WEB

8 Pages

-

BO AIRSPRAY-AUTOMATIC AME

2 Pages

-

SuperFinish SF 27

8 Pages

-

Finish 270

6 Pages

-

EPG_SL_5

2 Pages

-

TempSpray

6 Pages

-

PS 3.21 Spraypack

8 Pages

-

Finish 230 Lacquer Spraypack

2 Pages

-

PrimaTechCCM

4 Pages

-

profitech S

6 Pages

-

PrimaCube automatic system

4 Pages

-

BO Modular Painting System

4 Pages

-

SuperTech

4 Pages

-

ProfiTech

2 Pages

-

VertiCube

1 Pages

-

C4 HiCoat

4 Pages

-

PrimaTech Control Technology

4 Pages

-

Wagner Comfort Powder Centre

1 Pages

-

The C4 generation of guns

6 Pages

-

Inline pump IP5000

2 Pages

-

EPG-DP 5 Multi Control

2 Pages

-

DigiTech

2 Pages

-

Wagner 3D Pro Coating

1 Pages

-

Unica 4-270

4 Pages

-

TwinControl

8 Pages

-

SupraCoat

4 Pages

-

RoboCoat

2 Pages

-

IceBreaker®

8 Pages

-

WAGNER Thermo-technology

2 Pages

-

The WAGNER Thermo-System

2 Pages

-

GA 3000 AC

4 Pages

-

Evobell

4 Pages

-

Electrostatic guns

8 Pages

-

AirCoat guns

4 Pages

Archived catalogs

-

Cobra® 40-10

8 Pages

-

SuperCube_en

4 Pages

-

C4_brochure

4 Pages